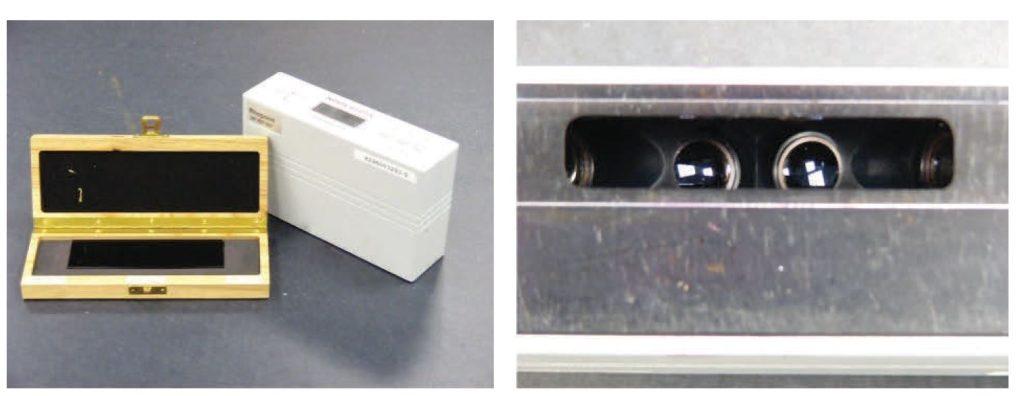

Glossmeter

A glossmeter measures specular reflection, or the capacity of a surface to reflect light. It is a scientific test internationally recognised to allow comparison of measurement values. As it is measuring the “gloss”

of the surface of a material, the more direct light that is reflected, the more obvious will be the impression of gloss. Hence, smooth and polished surfaces reflect more light than rough surfaces as the light is diffusely scattered in all directions.

The measurement results of a glossmeter are related to the amount of reflected light from a black glass standard with a defined refractive index. The measurement value for this defined standard is equal to 100 gloss units (calibration). Materials with a higher or lower refractive index can have a measurement value above and below this value accordingly (see Table below). By using reflectometers, the reflected light of a surface is measured in an angle range. The light source is projected over the sample surface onto the opening of an aperture. A photoelectronic detector then measures the light passing through the aperture. Common geometries and their performance indicators are shown in the table below. ISO 2813 describes the methodology for the determination of gloss value at 20°, 60° and 85° for paints and varnishes.

For glossmeter measurements of glass specimens, a black wrap may be used to minimise the reflected light from the second surface. Common application is the monitoring at various stages of the manufacturing process, construction, and operation of materials in a facility. Materials requiring such monitoring include:

– paints

– powder and anodised metals

– plastics

– glass

– polished stone