Electrical

Scroll down for links with more details on :

– General Performance and Hazards

– Transformer

– Cable and Wiring

– Distribution Equipment

– Protective Device

– Lighting

– Standby/Emergency Power

– Grounding and Lightning Protection System (LPS)

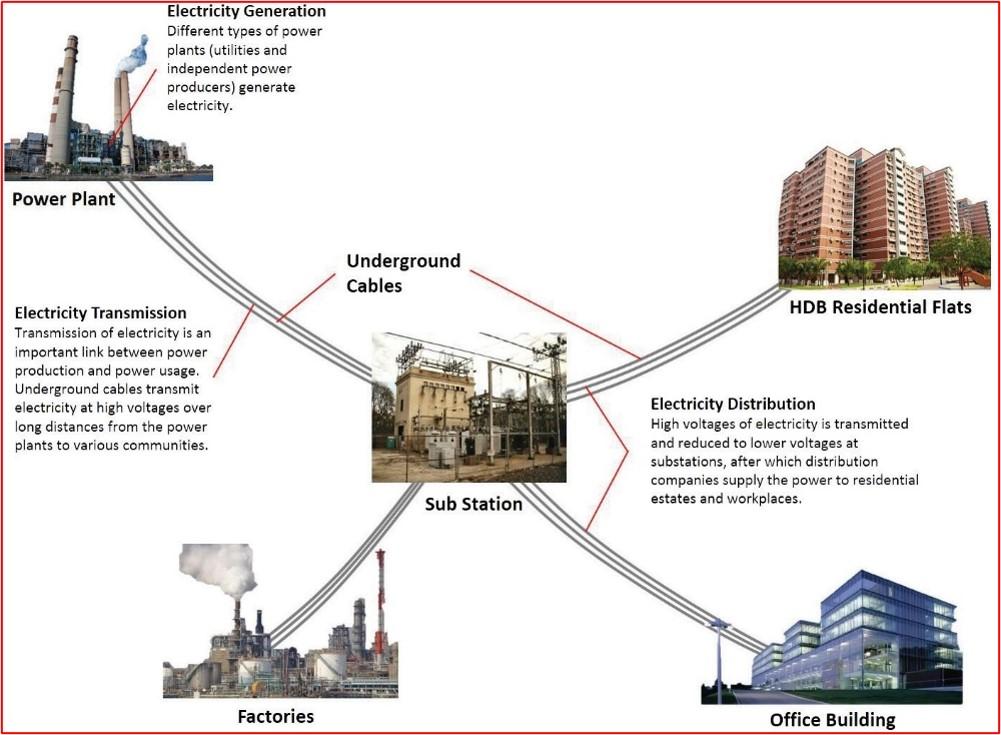

The electrical system plays an important role, particularly in modern commercial buildings, which demand for complex and sophisticated electrical systems to meet and support new innovation and technology in this fastchanging environment. The figure below shows the transmission and distribution grid structure within the power industry. A typical electrical system of an estate or a tall commercial building will start at the main services entrance where the incoming electrical supply from the service provider is located; the electrical energy will then go through a series of voltage step-down processes before being distributed to devices utilising the power at the end of the line.

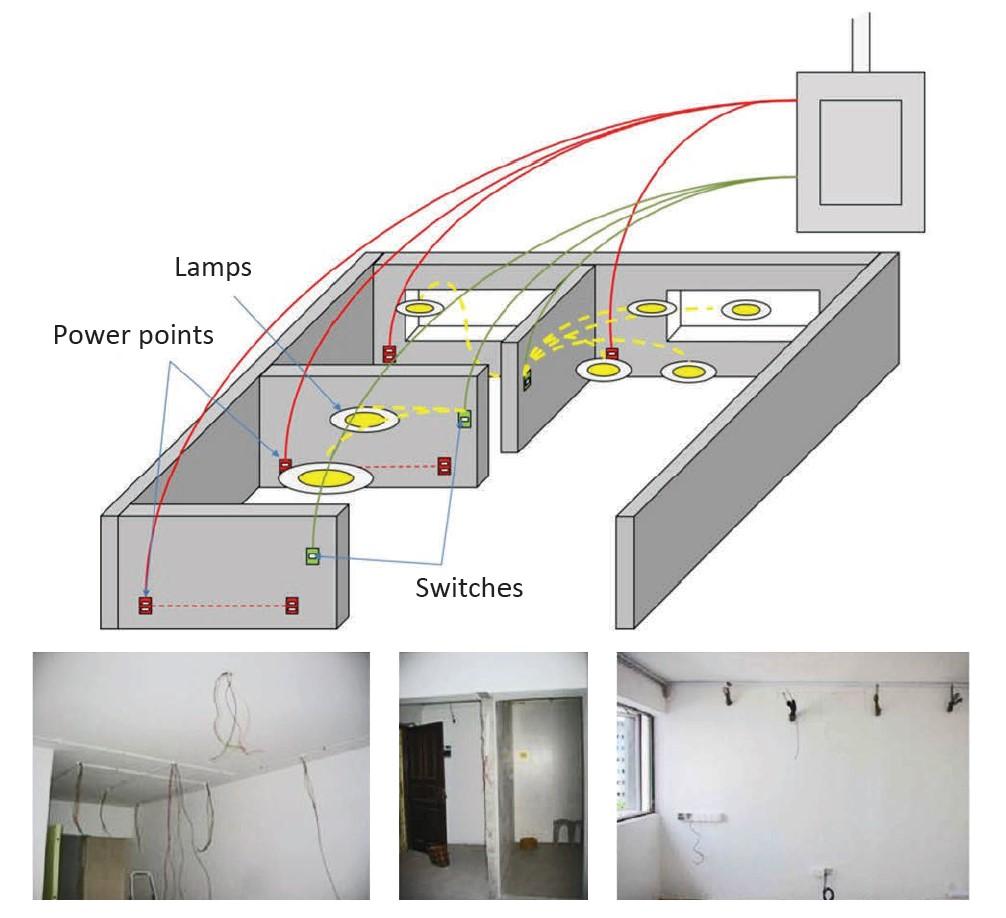

The figure below shows the electrical system of a typical residential building.

Conventionally, corrective and preventive maintenance has always been adopted in maintaining building systems and services. Regular inspection, testing, repair, and replacement formed a major part of the maintenance of building systems and services. However, in order to maximise the efficiency and effectiveness of electrical systems and avoid any circumstances that would affect their performance throughout a building’s life cycle, predictive maintenance incorporating maintainability issues should be taken into account from the design stage.

Maintainability of Electrical System

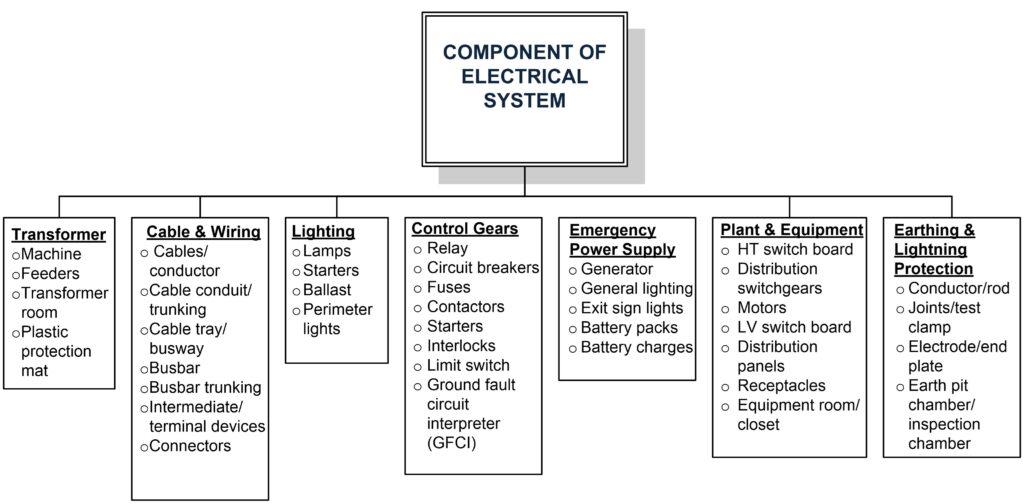

An electrical system consists of various components and subcomponents, such as transformer, cabling and wiring, plant and equipment, control gear, lighting, an emergency power supply, as well as earthing and lightning protection. Lack of proper maintenance will result in system unreliability, high hazard and shortened life spans of plants and equipment, resulting in the system requiring frequent and expensive repairs and replacements. In the worst case, fires, systems shutdowns, injuries, and deaths may occur.

Reference is made to:

Electrical Installation

- SS 638 — Code of practice for electrical installation

- NFPA 70 — National Electrical Code

- BS 7671 — Requirements for electrical installation

Lightning Protection

- SS 555 — Standard for protection against lightning

- NFPA 780 — Standard for installation of lightning protection system

- BS EN 62305 — Standard for protection against lightning

Maintenance

- SS 538 — Code of practice for maintenance of electrical equipment of electrical installations

- NFPA 70B — Standard for electrical equipment maintenance

- BS 6423 — Code of practice for maintenance of low-voltage switchgear and controlgear

- BS 6626 — Maintenance of electrical switchgear and controlgear for voltages above 1 kV and up to and including 36 kV

Earthing

- SS 551 — Code of practice for earthing

- NFPA 780 — Standard for the installation of lightning protection systems

- BS 7430 — Code of practice for protective earthing of electrical installations

Testing and Commissioning

The main tests for electrical works are:

- Insulation Resistance Test

- RCCB Trip Test

- Polarity & Continuity Test

- Earthing Test

The insulation resistance (IR) test or Megger test is a spot insulation test to assess the condition and reliability of an electrical equipment or circuit. Being portable, it is an adequate non-destructive test (NDT), especially for preventive maintenance for a facility with the electrical system exposed to harsh environments, e.g., temperature/humidity extremes, wetting/drying and chemical contamination.

Residual Current Circuit Breakers (RCCBs) refers to residual current circuit breakers, a “current” sensing device that contains a switch that will “trip” whenever a fault occurs in the connected circuit. The principle lies in the fact that the current in the live wire should be the same as the returning current in the neutral. In the case of a fault, the returning current from neutral is reduced. When this happens, the difference in current (residual current) is detected by the RCCB system and trips off the circuit. The functionality of RCCBs today can be easily tested by the use of the built-in test button on a regular basis.

A polarity and continuity tester are used to ensure that wiring connections to socket outlets and fittings are correct. An earthing test provides impedance measurements to ensure the reliable connection of the ground electrode between the electrical system and the Earth.

The design, installation and maintenance of electrical systems differ significantly based on power rating. In the Code of Practice for Electrical Installations, 600V is considered low voltage and is usually employed in commercial buildings in Singapore. The usual electrical system components are: transformer, wiring, distribution equipment, protective device, lighting, standby/emergency power supply, and grounding and lightning protection system.

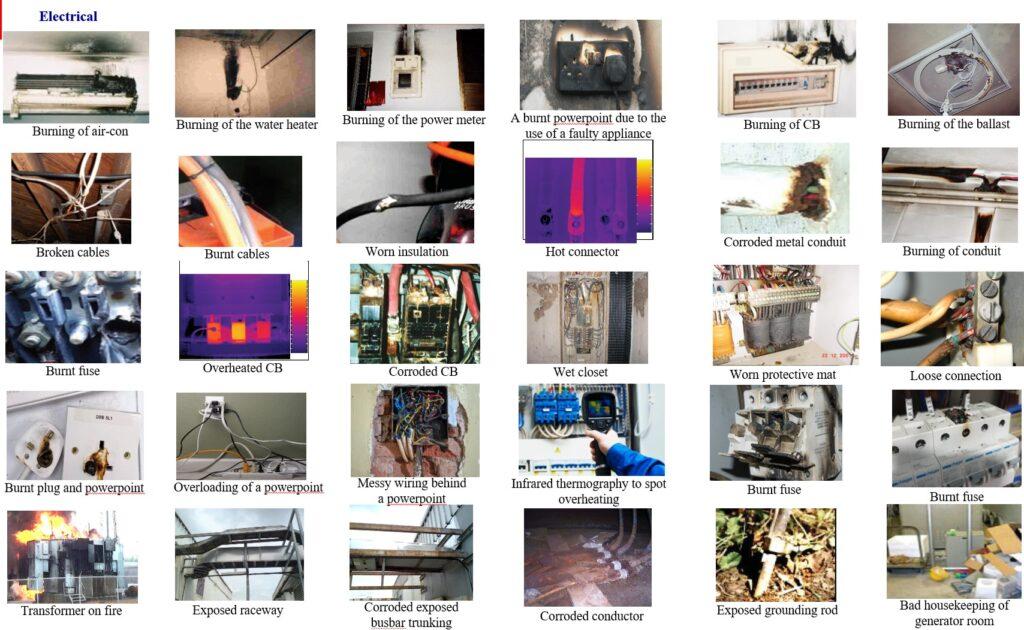

Common Defects

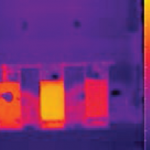

Electricity is notorious for claiming lives and causing injuries. It is also closely related to fire hazards, as it supplies the spark or arc — one of the components of the fire triangle — from overheated devices, loose connections or damaged insulation. Any accidental bridging of a gap between two conductors or a charred insulation can generate an arc.

IEC 60364 (the International Electrotechnical Commission’s Standard on Electrical Installation of Buildings) and BS 7671 (Requirements for Electrical Installation) lay out the protection measures for persons and

installations. For low-voltage electrical installations, protection against direct contact must be provided by (i) a complete covering with insulation corresponding to the minimum test voltage required for the primary circuit, and (ii) barriers or enclosures with a degree of protection against the insertion of a solid body that exceeds 12 mm in diameter and is up to 80 mm long (IP2X) or contact with a finger (IPXXB). For protection against indirect contact, IEC 60364-4-41 lays out several protection concepts to avoid the hazard from touch voltages (limit values 50V AC and 120V DC for normal fixed installations) in the event of a malfunction, with the most commonly used in switchgear installation design being (i) protection by an automatic tripping of the power supply, and (ii) protection by equipment of safety class II (double insulated equipment). Explosions within oil-insulated transformers and over-burnt dry transformers

have been reported. Apart from hazards, system performance is another area of concern.

Many defects of electrical system occur due to other services that share the same service spaces (e.g. seepage through building components, mismatch of lighting grid, etc.). Information regarding these critical aspects should be conveyed to the relevant professionals at the outset of the project. The identified electrical system defects refer to (a) general performance and hazards; (b) transformer; (c) cable wiring; (d) distribution equipment; (e) Protective device; (f) Lighting; g) Standby/Energy/Power; (h) Grounding and Lightning Protection System and Earthing defects. Integrating predictive maintenance and maintainability issues at the design stage could maximise the electrical systems’ efficiency as well as the effectiveness of its performance throughout a building’s life cycle.

General Performance and Hazards

Grounding and Lightning Protection System (LPS)