Plumbing and Sanitary

Scroll down for links with more details on :

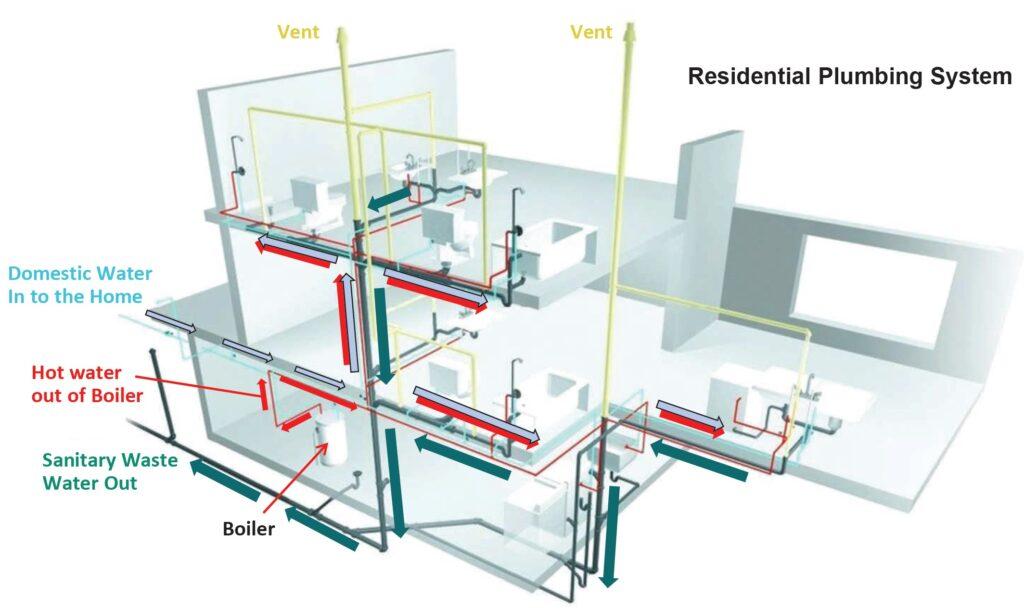

– Supply Pipes and Drainage

– Underground and Overhead Storage Tank

– General Pumps and Sewage Pumps

– Sanitary / Sewerage

Sanitary-plumbing systems form one of residential buildings’ most important building services. The breakdown of water service, sewerage and other sanitary-plumbing features is disruptive due to the inconvenience caused by the downtime and, more importantly, because of the possible safety and health concerns. Reported accidents include the consumption of contaminated water from faulty water service systems by users and the inhalation of poisonous gases by cleaners while cleaning the sewers.

Without proper design considerations and planning executed during the design stage, sanitary-plumbing systems will not be maintainable or operate efficiently. The results of ignoring preventive maintenance aspects are shorter service life, premature replacement of components, and increased operational costs due to problems such as leakages in piping, etc.

Maintainability of Sanitary-Plumbing System

For sanitary-plumbing systems, design changes are very costly and tedious to implement during the operation stage. Considering maintainability during the design stage ensures:

- longer lifespan of systems and components,

- lower operating costs by performing at high efficiency,

- lowering unscheduled downtime, by preventing failures, and

- lowering scheduled downtime, by decreasing the time required to perform a particular maintenance task.

Ignoring equipment availability and maintenance requirements and not taking the design of access for maintenance equipment into consideration are the main factors contributing to faulty designs in M&E services.

Inspections and adjustment tasks should be performed easily and comfortably if specific provisions for carrying out visual inspections and maintenance actions are incorporated into the original design. It is easier to lubricate assemblies and components quickly and effectively if such systems are readily available.

If standardised parts and assemblies are recommended and implemented at the design stage, repair time can be reduced to the minimum at the operation stage, which makes up the highest proportion of the LCC. Systems with simple and effective designs will assist in reducing redundancy. These, in turn, reduce failure rates, as the systems are customised to fit the surrounding environment, allowing possible causes of system failure to be more quickly understood, ascertained and detected.

Reference is made to:

- SS 636 — Code of practice for water services

- SS 375 — Suitability of non-metallic products for use in contact with water intended for human consumption with regard to their effect on the quality of the water

- PUB — Code of practice on sewerage and sanitary works

- SS 608 — Code of practice for gas installation

- BS EN 806 — Specifications for installations inside buildings conveying water for human consumption

- BS 8554 — Code of practice for the sampling and monitoring of hot and cold water services in buildings

- BS 8558 — Guide to the design, installation, testing and maintenance of services supplying water for domestic use within buildings and their curtilages

- ISO/DIS 24510 — Activities relating to drinking water and wastewater services — Guidelines for the assessment and for the improvement of the service to users.

Testing and Commissioning

The main tests for plumbing and sanitary are:

- Water sample test

- Water pressure test

The quality of drinking water is regulated by the Environmental Public Health (EPH) (Quality of Piped Drinking Water) Regulations, which are based on the WHO Guidelines for Drinking Water Quality. Water

samples are collected and analysed chemically and bacteriologically at an accredited water-testing laboratory.

All sewers below 600 mm in diameter must be tested before being surrounded and covered. This is done by filling said sewers with water. The pressure is measured from the highest point of the pipeline being tested and must be a 1.5 m head of water. Pipelines should not be accepted until they have withstood the required pressure for 30 minutes without a loss in excess of 1.5 L for 100 m, for each 300 mm in diameter. Sewers of 600 mm and above in diameter need not be hydraulically tested. They may be inspected via CCTV. For man-entry sewers, a manual inspection must be carried out.

All pumping mains of 600 mm or less in diameter must be tested hydraulically at convenient lengths before being covered up. Water must be forced into the pipes by means of a pump fitted with a pressure gauge, to indicate the pressure at the lowest point for the section being tested. The test pressure must be 1.2 N/mm2 for all classes of pipes. Pumping mains should not be accepted unless the loss of water is at a rate less than 10 cc per mm diameter per km of pipeline for 30 minutes.

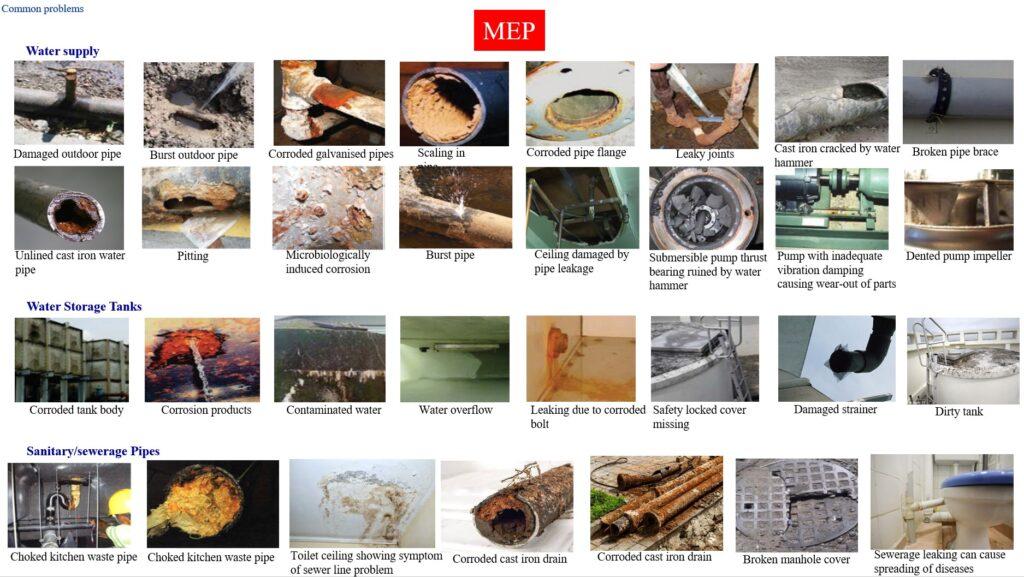

Common Defects

Apart from wasting precious energy and water, sanitary-plumbing systems can become a source of fatal contamination unless they are properly designed, constructed and maintained. Visible cleanliness of water alone cannot be considered satisfactory. Particularly in densely populated cities, waterborne diseases may spread quickly unless a high standard of public health is maintained.

Many codes of practice, standards and guides of design and operation handbooks, along with detailed consideration for major issues such as piping, valves, pumps, LLCs, etc., are available. Major problems all

around the world, such as leakage resulting in water scarcity and sewage contamination of potable water causing sickness and recurrent cases of Legionella, are reported frequently. The root causes of many of these problems are the corrosion and wearing out of metallic parts, which are common problems in pipelines, particularly in the consumer’s plumbing fittings. Corrosion favours bacterial growth, developing high concentrations of lead and copper components within the system, hence leading to dirty and contaminated water. Researchers have drawn attention to various problems related to sanitary-plumbing systems, such as lead contamination, biofilm formation, etc.

The sanitary and plumbing systems’ main functions are to provide hot and cold water and remove liquid waste or liquid borne solid waste. For any water supply, especially potable water, any pollution, obnoxious taste or odour and toxicity should be completely prevented. In order to ensure the health and safety of the public and cleaning personnel, it is mandatory to avoid any blockage or flooding of sewerage system by controlling the surcharge. The identified sanitary and plumbing systems’ defects pertain to (a) general plumbing issues (e.g. water supply general defects and leaky joints in inaccessible area); (b) Underground and overhead storage tank; (c) water supply system (e.g. corrosion and scaling of pipe/valve, damaged piping, water hammer and excessive vibration); (d) General pumps and sewage pumps; (e) Sanitary fixtures and fittings, (f) Sanitary piping; (g) Sewerage ejectors; and (h) Sewer and manhole. Design changes concerning sanitary and plumbing systems should not be encouraged since it is highly expensive and challenging to implement during the operation stage. Proper design, construction and maintenance of sanitary and plumbing systems should also put extra emphasis on ensuring a high standard of health of building users.

Underground and Overhead Storage Tank

General Pumps and Sewage Pumps