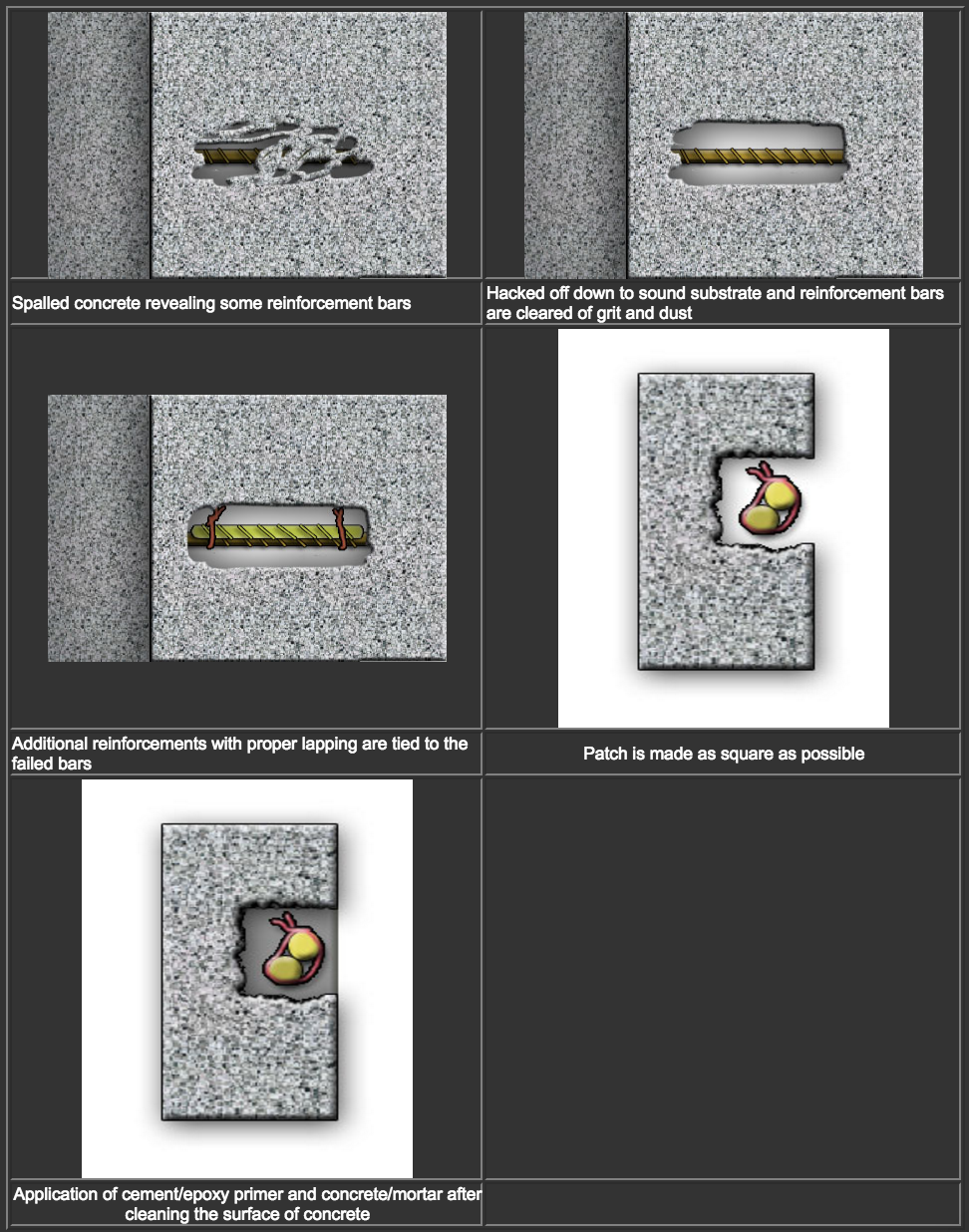

Conventional Patching Method

Removal of the salt-contaminated concrete, patching, and the application of waterproofing membranes, are some of the possible treatments that, alone or in combination, have been traditionally used to rehabilitate corrosion-damaged infrastructure. The application of waterproofing membranes is of great benefit on new structures. These membranes prevent, or at least retard, the ingress of chlorides to the reinforcement. But when the chloride content in the concrete in contact with the rebars equals or exceeds the corrosion threshold, membranes will have no significant impact on reducing the corrosion. In concrete heavily contaminated by chlorides, membranes could only reduce corrosion rates if they completely encapsulated the concrete, thereby preventing any access of oxygen to the steel reinforcement.

Source: Coventional patching for steel reinforcement by R. Brousseau, http://www.nrc.ca/irc/

Application

The process involves following steps

- remove all the weak and defective concrete with a hammer and chisel or other approval electronic tool

- remove all grit and dust in rebar. Wire brush can be then used to remove the rust at reinforcements. (If the rebar’s sectional area reduces more than 15%, additional rebar with proper lapping must be added).

- the patch should be cut out as square as practicable

- clean the surface of concrete and wire brush

- apply a prime coat using an approved rust inhibitor and a coating of approved “bonding aid” to the exposed rebar over the hacked surface to ensure the good adhesion with repair material

- wet the surface thoroughly

- apply concrete/mortar (polymer mortar or epoxy mortar) over a wet surface in a layer of no more than 20mm

- cure the mortar for four hours between layers