Case 3

- Introduction

- Causes of Defects

- Good Practices

- Standards

- Maintenance and Diagnostics

- Remedial

- Similar Cases

- References

Maintenance and Diagnostics

Maintenance

In general, good quality concrete does not require extensive maintenance. However, due to external factors it might have some defects even before reaching its design life.

Regular inspections and checking should be hence carried out periodically at regular intervals to detect these defects and to take remedial action to remove these defects. An efficient inspection system should be adopted to ensure the conduct of regular checks such as visual inspections periodically.

Suitable instruments and techniques should be used to diagnose defects properly. Diagnosis involves a process in which experts investigate the buildings’ conditions, carry out tests, evaluate, make recommendations for remedial actions where necessary and predict the future performance of a building.

The important factors to be noted for cracks are:

- width, direction and location

- whether live, dead or growing

- isolated or random

- widespread or confined to particular areas

- associated with other defects or rain entry

- surface erosion effects

Diagnostics of Defect (see also NDT)

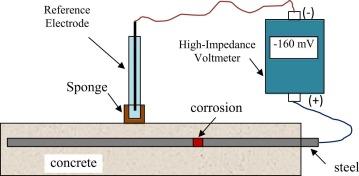

Half Cell Potential Measurement

The main application of Half cell measurement is to evaluate the probability of corrosion of the steel reinforcement embedded in the concrete members. This is measured in relation to the potential value readings.

Profometer (Covermeter) – rebar scanner

Profometers (covermeters), based on the principles of electromagnetism, are use to locate and to measure the depth of rebar (concrete cover).

Carbonation Test

The depth of carbonation in the freshly exposed surfaces of concrete can be determined by spraying with phenolphthalein indicator solution. In the case that pink colour appears, it means that the concrete still retains its alkaline nature and carbonation is minimal.

This test can be done in the laboratories as well as on sites.

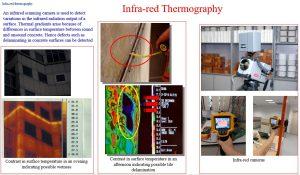

Thermography

Thermography can be used to identify the position of cracks. A range of crack widths, representing mechanical damage, has been induced under controlled laboratory conditions.

The method is based on the characteristics of heat flow phenomenon, in a conductive medium of specific geometry, which is intended to model predetermined boundary conditions. Thermo tracer is an advanced equipment used in thermograph technology.