Escalator

Among many important functional decisions which must be taken by the designer of a multi-storey building, probably none is more than or as important as the proper selection of the mechanised transportation systems, which include escalators, elevators/lifts, and moving walkways. Not only

are these systems critical to the users, the quality of these systems also affects the tenant’s choice of space against competing buildings. Rising construction costs and the persistent demand for quality space increases the value of designing a mechanised transportation system to deliver the most effective way of moving traffic within the building. For maximum serviceability and economy, mechanised transportation must be planned to meet the requirements of each building and its users.

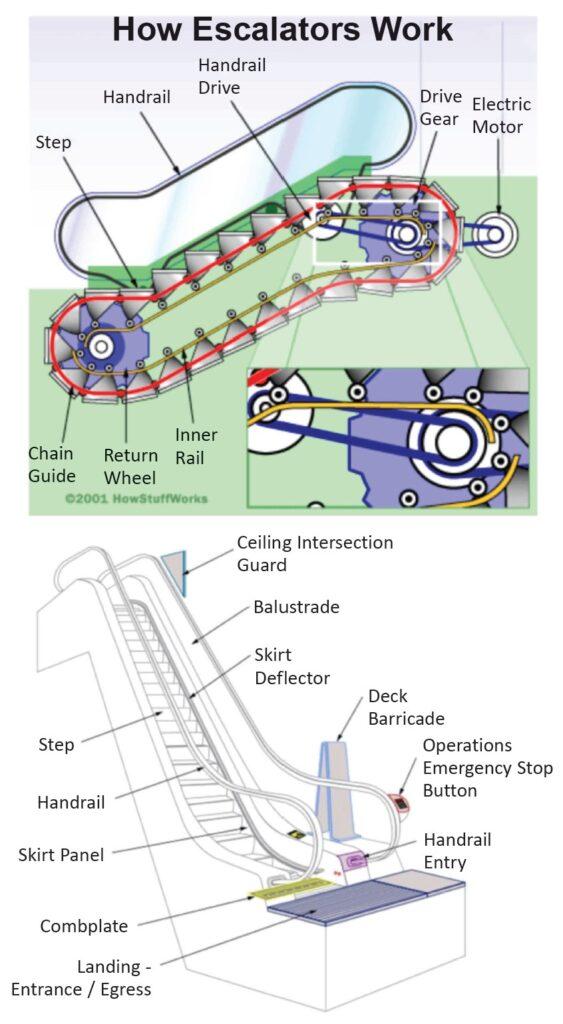

An escalator is a type of vertical transportation in the form of a moving staircase which carries people between floors of a building. It consists of a motor-driven chain of individually linked steps on a track which cycle on a pair of tracks which keep them horizontal. Considerations for maintainability when designing the escalator could ensure its optimal required performance while simultaneously minimising costs for maintenance and operations throughout the building’s life cycle.

An escalator is like a “moving staircase” designed to transport passengers, usually over a short vertical distance. It follows the basic principle of a conveyor belt, with each step attached to a pair of rotating chain loops, called step chains, which pulls the stairs in a constant cycle. The chains, in turn, are looped around two pairs of drive gears. A motor rotates the drive gears, which, sequentially, gets the entire system rotating.

Bottom: A schematic diagram of a typical escalator. (Courtesy of TSSA.)

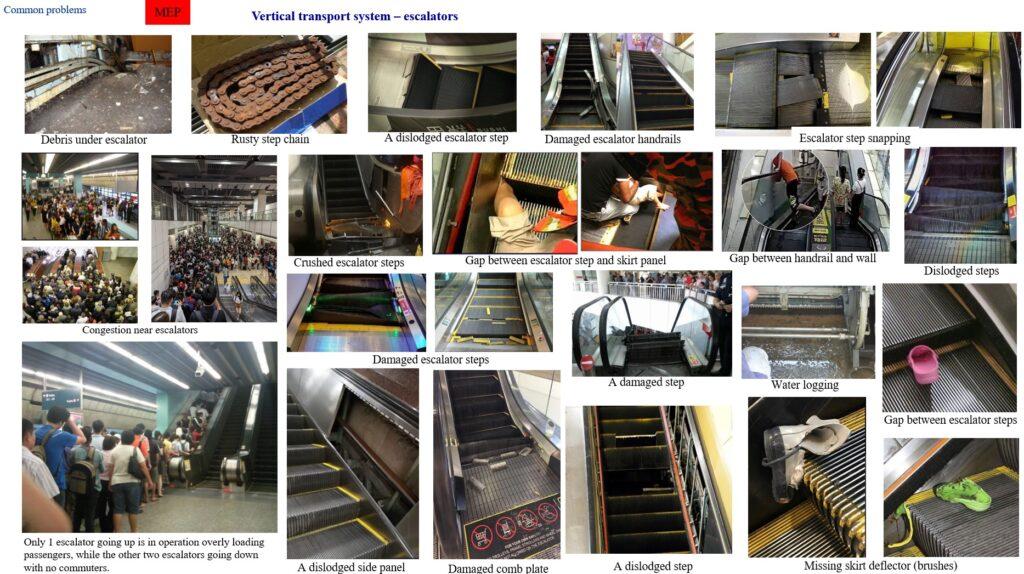

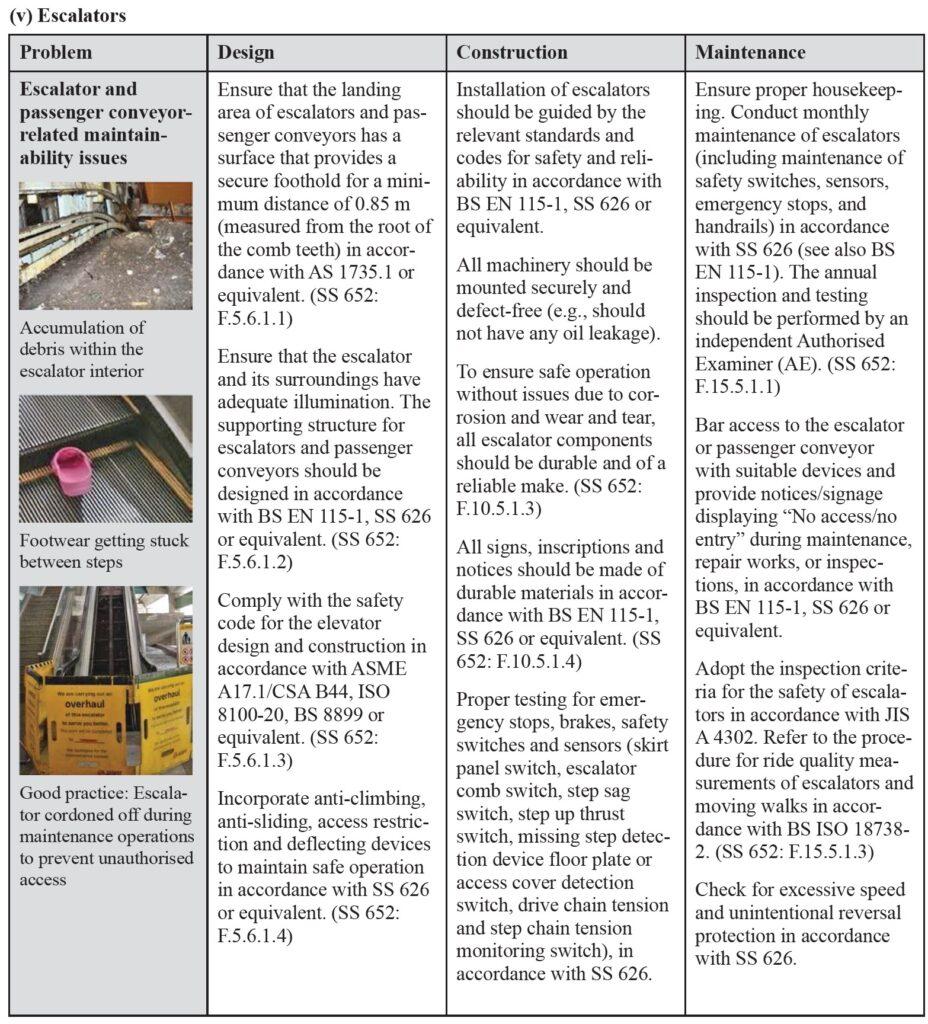

Although many escalator incidents are related to user behaviour, faults arising from the hardware are not uncommon :

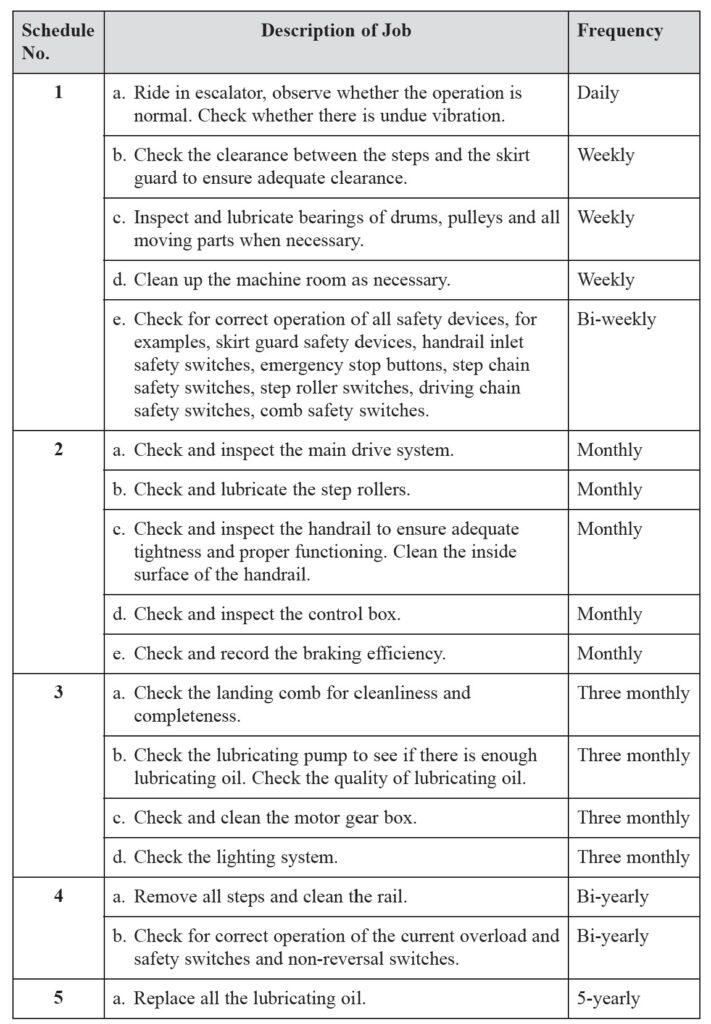

Hence a thorough maintenance schedule for the safe use of escalators is essential, especially for MRT stations and busy shopping malls. The table below shows an example of a maintenance schedule for escalators at a busy shopping centre.

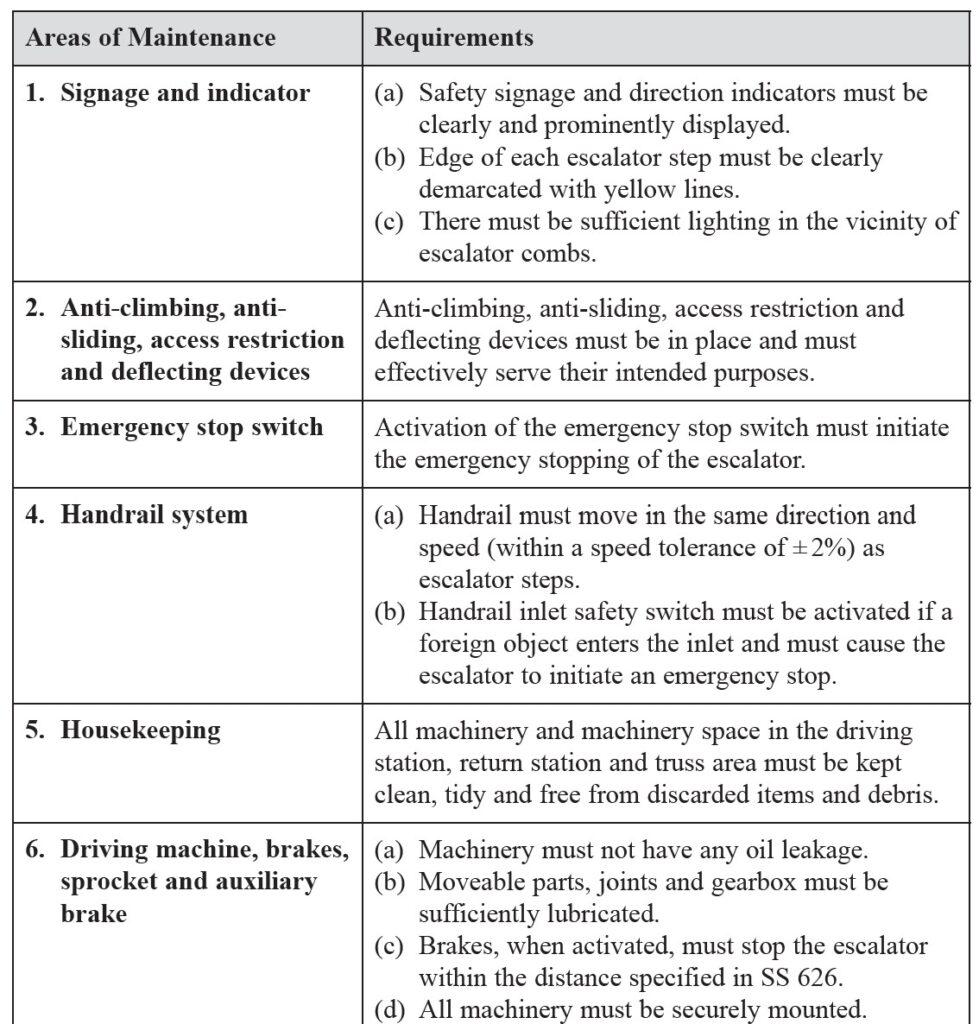

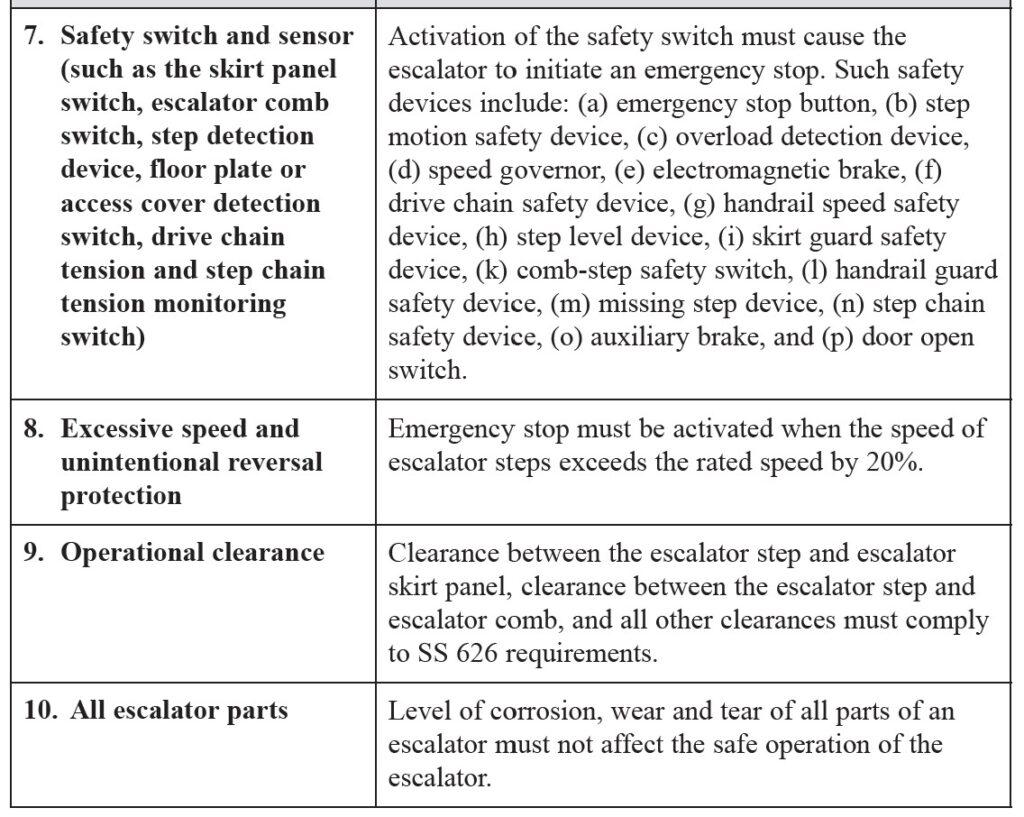

SS 626 (formerly CP 15) describes the good practices for the design, installation and maintenance of escalators and moving walks. In general, all escalator owners are required to engage an escalator contractor who is registered with BCA to maintain their escalators every month and in accordance with the requirements in the codes and standards as specified in SS 626. In addition, registered escalator contractors will have to maintain escalators according to 10 specific maintenance outcomes, as shown

in table below :

Maintainability of the Mechanised Transportation System

A mechanised transportation system is one of the most sophisticated and specialised systems in a facility, with an assembly of mechanical, electrical and hydraulics subsystems distributed from the basement to the roof. Although modern vertical transportation systems are designed and manufactured under tight quality control, once in service, like any other electro-mechanical device, it requires periodic maintenance. A systematic maintenance programme is essential for efficient performance throughout its useful service life whilst balancing customer satisfaction, corporate profit and environmental friendliness. It is important to bear in mind the importance for maintainability when designing the system, since the mechanised transport system is an essential building service for most high-rise buildings and is often difficult to replace.

The mechanised transport systems characteristically have a relatively long service life of 15–30 years. Therefore, it is important for designers and building owners to ensure that the design and quality of the product enable continuous and easy maintenance activities for safety and continued performance, and cleanliness, as well as an aesthetically pleasing appearance.

There is a need to identify shortcomings in a system’s design or a material’s function before it is placed into use, as it is crucial to construct a system component that is maintainable and that functions as it is intended to. Such a practice will be able to sustain its optimum desired performance while, at the same time, minimising maintenance and operation costs during the life cycle of building. The degree to which the design of a building embraces maintenance considerations has a major impact on its performance.

Reference is made to:

- SS 550 — Code of practice for installation, operation and maintenance

of electric passenger and goods lifts - BS EN 81 — Safety rules for the construction and installation of lifts.

Lifts for the transport of persons and goods - ISO/TR 11071 — Comparison of worldwide lift safety standards

- ISO 8100-20 — Lifts for the transport of persons and goods — Part 20:

Global essential safety requirements - Building maintenance and strata management (lift and building maintenance)

regulations - AS 1735 — Lifts, escalators and moving walks

- JIS A 4302 — Inspection standard of elevator, escalator and dumbwaiter

- ASTM A17.1 — Safety code for elevators and escalators

- ASTM A17.2 — Guide for inspection of elevators, escalators, and

moving walks