Impact Echo Test

Principles

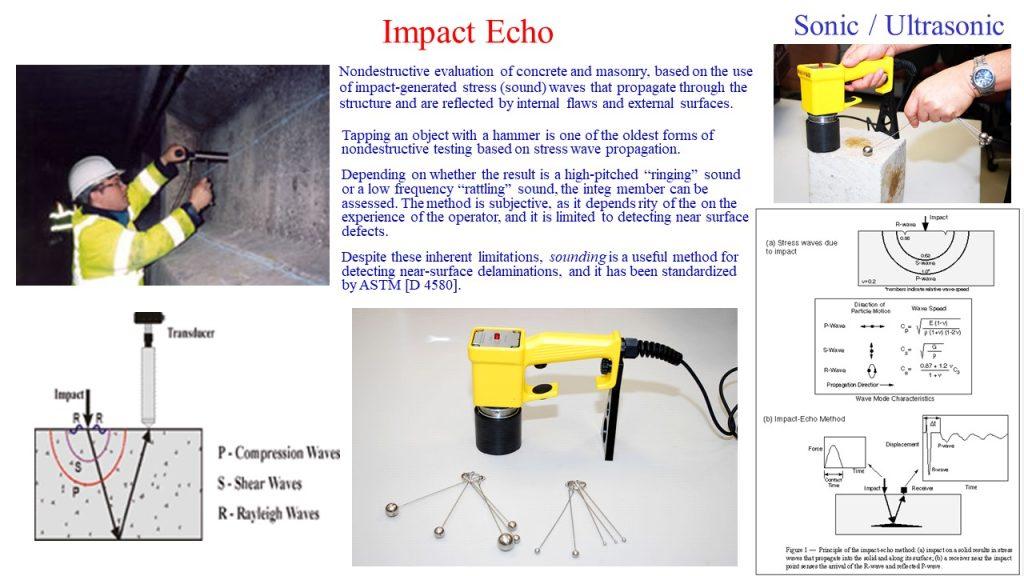

Impact echo is a non-destructive evaluation method for concrete and masonry based on the use of impact-generated compression waves that travel through the structure and are reflected by internal flaws and external surfaces. Tapping an object with a hammer is one of the oldest forms of non-destructive testing based on stress wave propagation. Depending on whether the result is a high-pitched “ringing” sound or a low-frequency “rattling” sound, the integrity of the member can be assessed. The method is subjective, as it depends on the experience of the operator, and it is limited to detecting near-surface defects.

Despite these inherent limitations, sounding is a useful method for detecting near-surface delaminations, and it has been standardised by ASTM D4580/D4580M-12.

It is used to determine:

– the location and extent of flaws such as cracks

– delaminations

– voids

– honeycombing

– voids in the subgrade directly beneath slabs and pavements

In the test, a short-duration mechanical impact is given to the tested path, produced by tapping a small steel sphere against the tested surface. The low-frequency stress waves that are generated propagate into the structure and are reflected by flaws and/or external surfaces. Surface displacements caused by reflections of these waves are recorded by a transducer located adjacent to the impact. The displacement versus time signal is transformed into the frequency domain, and plots of amplitude versus frequency (spectra) are obtained.