Strengthening

A cosmetic repair (filling and patching) does not work for a structural crack. The cause for the structural crack must first be evaluated before the most optimum repair method can be determined. This may involve stabilising the foundations such as underpinning, strengthening weakened elements such as reinforcing the structure with additional steel or other materials etc.

Underpinning

Underpinning is the process of strengthening and stabilising the foundation of an existing building. It involves excavating under an existing foundation and building up a new supporting structure from a lower level to the underside of the existing foundation, the objective is to transfer the load from the foundation to a new bearing at a lower level [1]. Examples of buildings that may require underpinning include:

– Buildings with existing foundation not large enough to carry their loads, leading to excessive settlement.

– Buildings overloaded due to change of use or partial reconstruction.

– Buildings affected by external works such as adjacent excavations or piling which lead to ground movements and vibrations.

– Buildings going for new extensions, e.g. higher storeys, new basements, etc..

– Buildings with new buried structures, e.g. service tunnels and pipelines in close proximity.

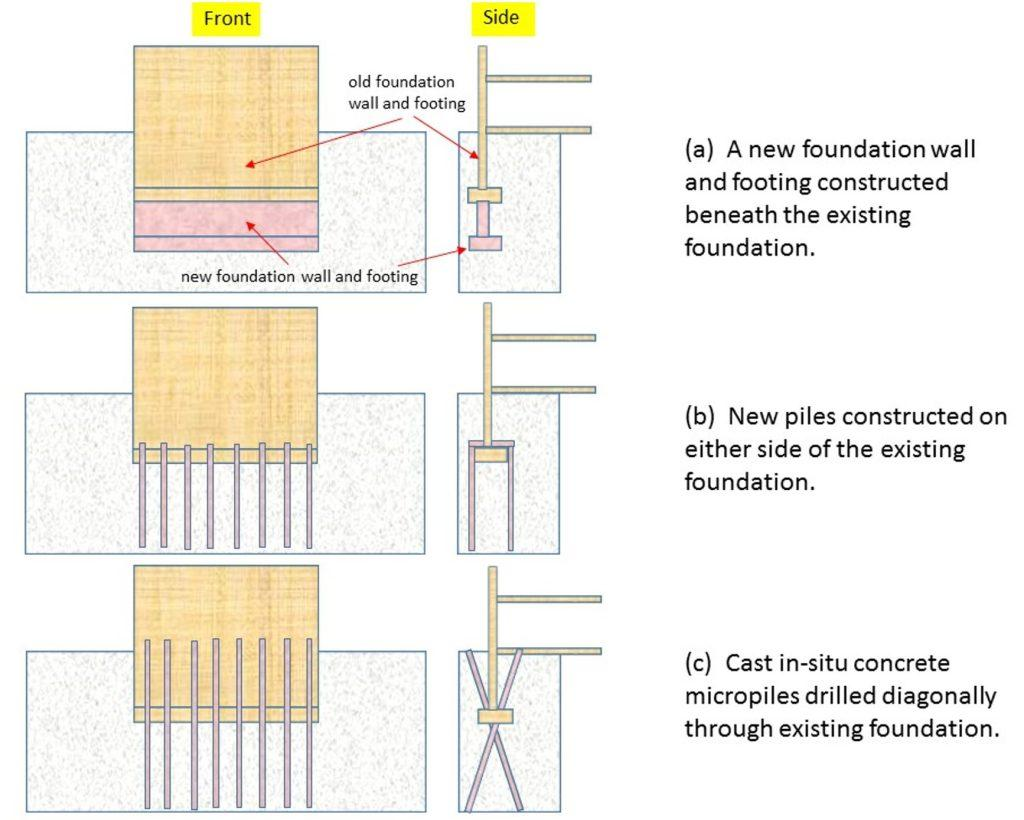

The capacity of an existing foundation may be increased by:

– Enlarging the existing foundations.

– Inserting new deep foundations under shallow ones to carry the load to a deeper, stronger stratum of soil.

– Strengthening the soil through grouting or chemical treatment.

A successful underpinning works relies heavily on an efficient temporary removal of load from the existing foundation before strengthening, and an efficient transfer of load back to the new foundation after the strengthening. The two common methods of supporting a building while carrying out underpinning work beneath its foundation are progressive and needling methods:

(a) Progressive method — Where the work is carried out in “discrete” or alternate bays so as to maintain sufficient support as work proceeds. Normally no more than 20% of the total wall length should be left unsupported. The bays are then joined together to form a continuous beam;

(b) Needling method — Where the foundation of an entire wall is exposed at once by needling, in which the wall is supported temporarily on needle beams threaded through holes cut in the wall. After underpinning has been accomplished, the jacks and needle beams are removed and the trench backfilled.

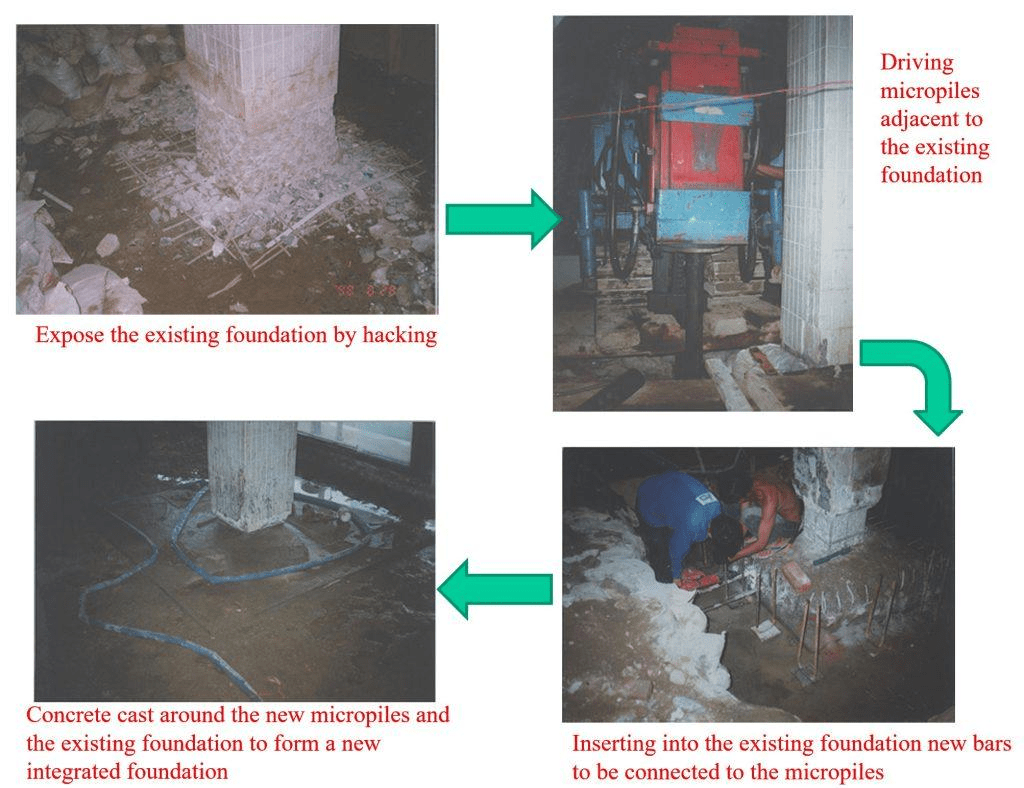

The use of micropiles for underpinning is suitable for locations with limited headroom, e.g. in a basement. Micropiles are small diameter (usually 100 mm to 300 mm) piles come in different lengths. An example

of underpinning using micropiles around an existing pad foundation is as follows:

- Expose the pad foundation by hacking away the slab, etc.

- Drive micropiles around the pad foundation.

- Join lengths of micropiles by welding or chemical methods.

- When the required depth is reached, grout the piles through a tremie pipe.

- Insert new bars into the pad foundation and connect to the micropiles.

- Cast concrete around the micropiles and the pad foundation as a new integrated foundation.

Fiber Wrap Strengthening

Fiber wrap or fiber-reinforced polymer (FRP) is one of the structural strengthening methods used to enhance the load-bearing capacity and structural integrity of an existing structures. The method involves applying or wrapping a high-strength fiber sheet (fabrics) made of carbon or glass fibers onto the surface of the structural element to be strengthened.

Procedure:

(1) Identify the locations for the strengthening.

(2) Surface preparation (cleaning, removal of loose materials, provide keys to enhance bonding etc.) according to the manufacturer’s instructions.

(3) Apply the bonding agent (adhesive or resin) if required by the proprietary system.

(4) Apply fiber wrap.

(5) Apply additional layers according to the manufacturer’s instruction, normally in a crisscross pattern to optimise load distribution.

(6) Provide curing for the material according to manufacturer’s instruction.

Carbon Fiber Strengthening

References

[1] M. Y. L. Chew, Construction Technology for Tall Buildings, 6th Edition, World Scientific, 2024.

[2] M. Y. L. Chew, Maintainability of Facilities – Sustainable FM for Building Professionals, 3rd Edition, World Scientific, 2024.