Concrete Spalling Repair

Removal of Rust Stains

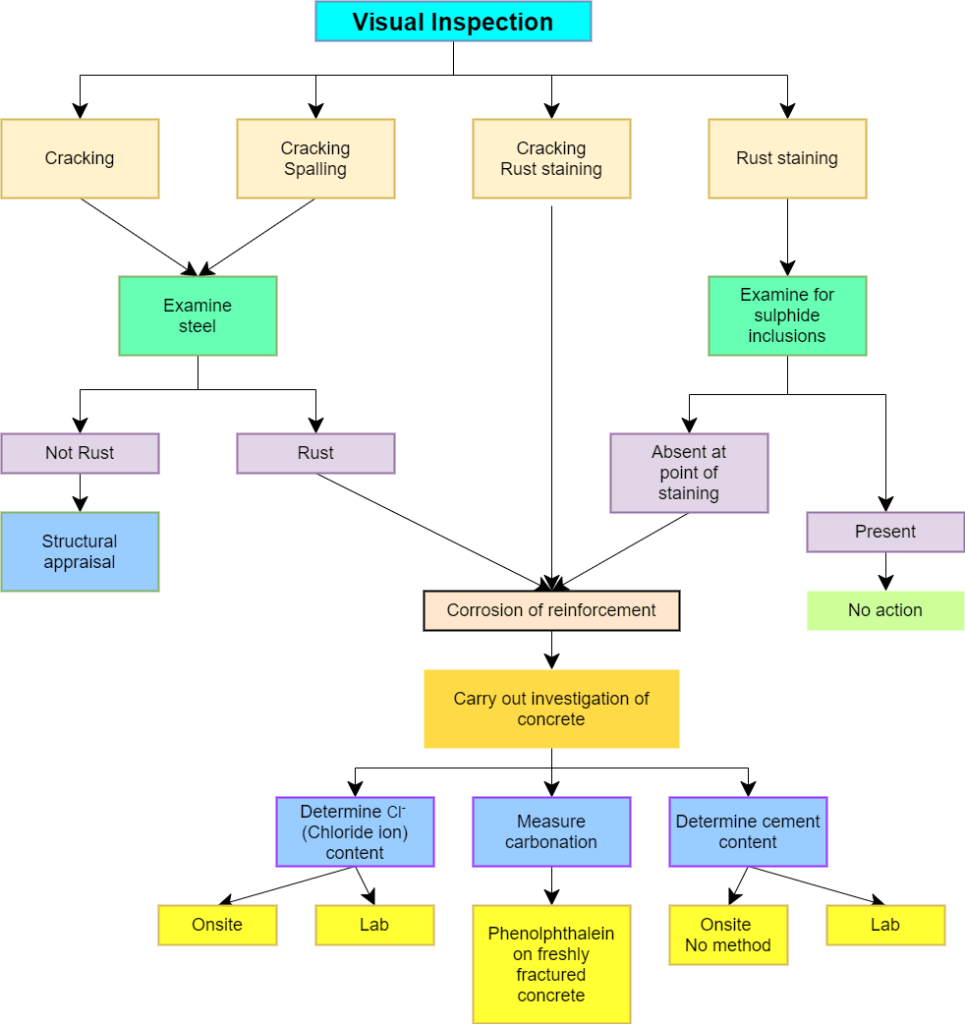

Stains of a rust colour on concrete can be caused by rusting of steel in or on concrete, either from the use of curing water containing iron, or from pyrites (iron sulfide) sometimes found in aggregates. Massive rust stains sometimes occur on the concrete supports of weathering steel structures.

Shallow rust stains yield to swabbing with a solution of 1 pound of oxalic acid in 1 gallon of water. This is a toxic solution and warnings on the label must be heeded. 2 or 3 hours after applying the solution to the concrete, scrub the surface with a stiff brush while rinsing with clear water. To speed the cleaning, add ½ pound ammonium acid fluoride to the solution. However, this makes the solution even more toxic and requires greater care in handling.

For removal of deeper rust stains, poultices or bandages containing sodium citrate or other chemicals may be required. Sandblasting and waterblasting sometimes are used on large stained surfaces, but can cause objectionable roughening of the concrete.

1. Repair of structural crack lines (Procedure of Surface Repair)

Surface repairs can be done on the floor slab if there are no signs of water seepage from underneath or widening of gap with time.

2. Polymer Modified Cementitious Grouting

This can be applied on the crack so that the final appearance of concrete structure closely resembles the concrete being repaired, in respect of strength and long term movement. Its characteristics are improved with regards to bonding, flexibility and time within which strength is gained.

3. Patching (Procedure of Patching)

This method is used to rehabilitate corrosion-damaged infrastructure, where the application of waterproofing membranes prevents, or at least retard, the ingress of chlorides to the reinforcement. However, when the chloride content in the concrete in contact with the rebars equals or exceeds the corrosion threshold, membranes will have no significant impact on reducing the level of corrosion.

The patching method is the most common repair method for minor concrete defects such as surface spalls. Two types of materials are commonly used for patching up by hand:

Cementitious mortars such as cement mortar and polyester-modified cementitious mortar.

Resin-based mortars such as epoxy resin mortar and polyester resin mortar.

4. Repair using epoxy injection (Procedure of Epoxy Injection)

One of the most versatile, crack repair method is epoxy injection. This method can be used to repair cracks which narrow more than 0.002in [4].