Case 1 – Structural Cracks

- Introduction

- Causes of Defects

- Good Practices

- Standards

- Maintenance and Diagnostics

- Remedial

- Similar Cases

- References

Maintenance and Diagnostics

Buildings require regular maintenance to continue to remain structurally safe for the intended users and occupants. Structural inspections are required to ensure that buildings are properly maintained, continue to be safe for its intended use and occupation, and do not pose a safety risk to the occupants and members of the public.

Frequency of inspection

Once every 5 years for non-residential building.

Once every 10 years for residential buildings (detached, semi-detached, terraced or linked houses that are used exclusively for residence, and temporary buildings are exempted from the inspection).

Period Structural Inspection (PSI) process

- The BCA serves the building owner a Notice for PSI of Buildings.

- The building owner shall appoint a Professional Engineer (PE) to inspect the building structures.

- The appointed PE shall conduct a structural inspection of the building.

- The appointed PE shall submit a visual inspection report to the BCA. The report shall include the necessary documents and recommended rectification work for any identified defects.

- The building owner shall engage a contractor to repair the defects as recommended by the appointed PE.

In general, good quality concrete does not require extensive maintenance. However, due to external factors, it may develop some defects even before reaching its design life. Regular inspections and checking should therefore be carried out periodically at regular intervals to detect these defects and to take remedial action to keep the structures in good condition. An efficient inspection system should be adopted to ensure that regular checks, such as visual inspections, are conducted periodically. Suitable instruments and techniques should be used to diagnose defects properly. Diagnosis involves a process in which experts investigate the buildings’ conditions, carry out tests, evaluate, make recommendations for remedial actions where necessary and predict the future performance of a building.

Diagnostics of Defect (see also NDT)

Vibration

Vibration may be (i) continuous (with magnitudes varying or remaining constant with time, e.g., machinery), (ii) impulsive (infrequent and occasional, e.g., heavy crane loading and unloading), or (iii) intermittent (with the magnitude of each event being either constant or varying with time, e.g., trains, impact pile driving, jackhammers). Common instrumentation used to measure such motions includes

gyroscopes, accelerometers and magnetometers.

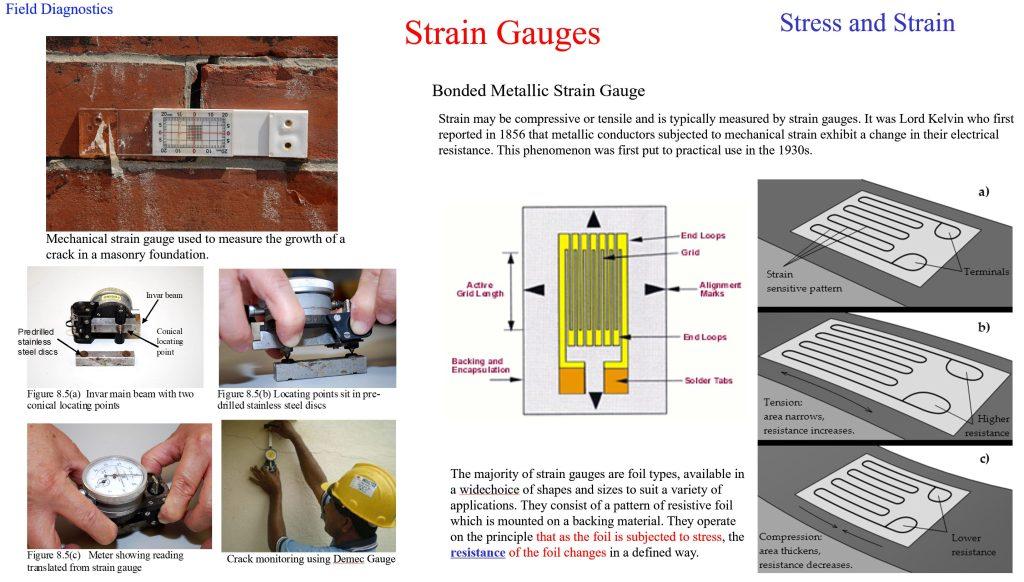

Strain Gauges

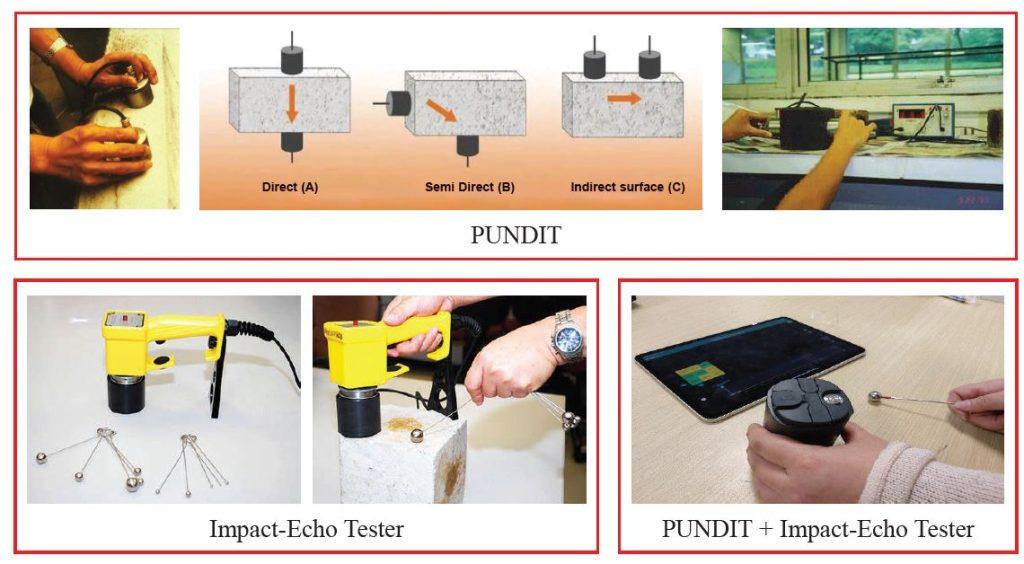

Ultrasonic Pulse Velocity (UPV)

UPV can identify non-homogeneous conditions such as voids, cracks and honeycombs using the optional hand-held terminal. This method can also be used to estimate the depth of cracks.

Profometer / Covermeter

Advanced Concrete Cover Meter & Rebar Detector – courtesy of Screening Eagle Technologies

Pull-off Test

Weber Tile Pull-Off Test On Site – courtesy Saint-Gobain Malaysia Sdn Bhd