Case 3 – Shrinkage Cracks

Navigation

- Introduction

- Causes of Defects

- Good Practices

- Standards

- Maintenance and Diagnostics

- Remedial

- Similar Cases

- References

Maintenance and Diagnostics

- Regular inspections should be carried out methodically at regular intervals to detect the defects.

- Checklists could be used so that a thorough checking could be made. Defects could be recorded, monitored and not be left unattended.

- Cleaning of car parks should be carried out at appropriate intervals of time to ensure the removal of dirt before they stain the structure permanently:

- Daily spot cleaning to clear up oil spots on the drive way to prevent oil stains from becoming stubborn and difficult to clean off.

- The floor of the car park is scrubbed clean once a week

- The surface drains have to be flushed to clear silt and dirt twice a year to prevent blockages.

Diagnostics of Defect (see also NDT)

Cracks can be visually detected. However, following equipment may be used to analyze a crack.

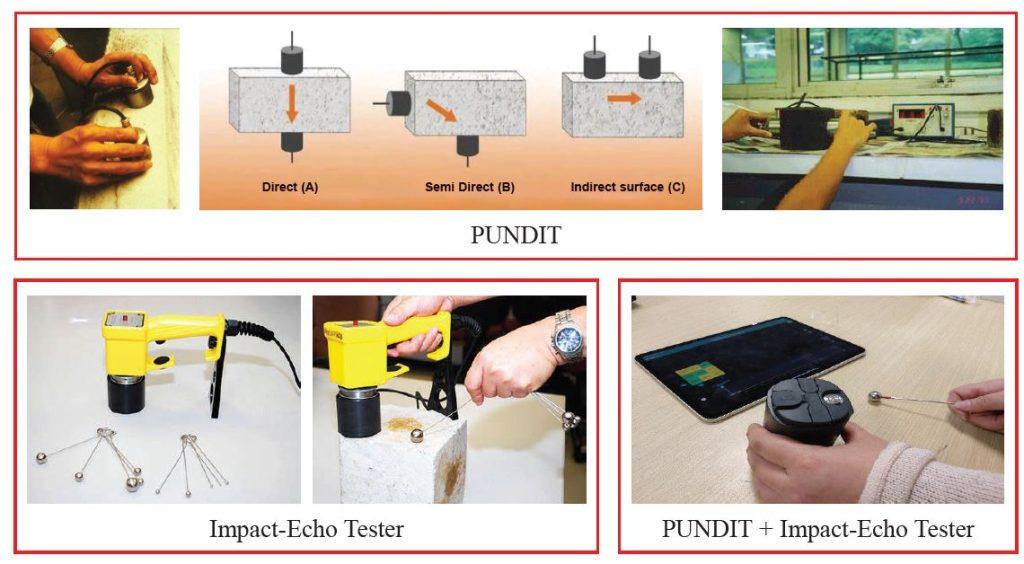

Ultrasonic Pulse Velocity (UPV)

UPV can identify non-homogeneous conditions such as voids, cracks and honeycombs using the optional hand-held terminal. This method can also be used to estimate the depth of cracks.