Case 2

- Introduction

- Causes of Defects

- Good Practices

- Standards

- Maintenance and Diagnostics

- Remedial

- Similar Cases

- References

Maintenance and Diagnostics

Maintenance

Consider availability of adequate water supply, drainage provisions and electrical power supply to choose a façade cleaning method. Records of cleaning operations (including photographs before and after cleaning, and drawings of nature of deposits, thickness and patterns) should be kept for buildings of significance in accordance with BS 8221-1, SS 509-1 or equivalent. Maintain the façade in a state as near as possible to its new condition. Ease of façade maintenance can be expressed by the frequency of necessary maintenance operations, labour and supplies necessary for each maintenance operation, and number of possible ways of removing stains, graffiti, etc., or ISO 7361 or equivalent.

Detect/determine staining of porous substrates by joint sealants (ISO/NP 16938-1). Adopt the recommendations for treatments for controlling organic growth in accordance with BS 8221-2, SS509-2 or equivalent. Repair painted surfaces damaged by wear and tear; wash down; remove defective paint film; apply sealer/primer (if necessary); and repaint in accordance with BS 6150, SS 542 or equivalent. TiO2 only works where there is sunlight. Conventional cleanings are still needed for non-coated areas. For areas coated with TiO2, conduct neutral cleaning annually.

Periodic cleaning is necessary to maintain the aesthetics of tiled façades. A neutral cleaning agent should be adequate if a periodic maintenance schedule is performed.

Periodic monitoring of water moisture on the facade is required to prevent excessive water seepage into the facade.

Diagnostics of Defect (see also NDT)

Visual Inspection

Visual assessment evidence is brown staining that may had permeate to the concrete surface without cracking of the concrete but usually it accompanies cracking or cracking of the concrete will happen shortly thereafter. For spalling the following information should be noted:

- Extent and number of affected areas

- Depth of failure

- Degree of detachment

- State of reinforcement corrosion

- Surface discolouration effects

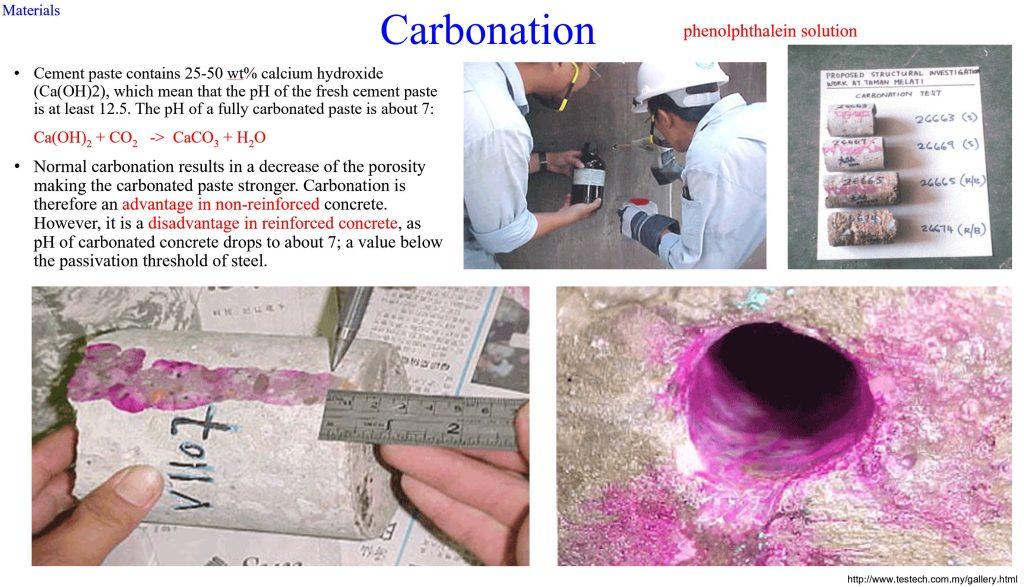

Carbonation Test

Spray concrete surface with phenolphthalein indicator, which registers a strong pink colour if the concrete retains its alkalinity.

Depth of carbonation is the location of the carbonation front and its proximity to the bars.

If the average carbonation depth approaches the average cover depth, more steel will start to corrode.

Half Cell Potential Measurement

The main application of Half cell measurement is to evaluate the probability of corrosion of the steel reinforcement embedded in the concrete members. This is measured in relation to the potential value readings.

Profometer (Covermeter) – rebar scanner

Profometers (covermeters), based on the principles of electromagnetism, are use to locate and to measure the depth of rebar (concrete cover).

Eddy Current Test

Eddy Current NDT is an inductive technique which employs a probe (coil with a AC current) placed close to the inspected material. When an AC current flows in a coil in close proximity to a conducting surface the magnetic field of the coil will induce circulating (eddy) currents in that surface.

The primary flux in the Figure above induces eddy currents in the material which give rise to a secondary flux. The secondary flux is then coupled back to the coil which affects its impedance. Thus the magnitude and phase of the eddy currents will affect the loading on the coil and thus its impedance. If a discontinuity (defect) is present in the material the eddy current density will be changed which can be observed as a change in coil impedance.

See also Concrete Spalling and Reinforcement Corrosion.