Case 3

- Introduction

- Causes of Defects

- Good Practices

- Standards

- Maintenance and Diagnostics

- Remedial

- Similar Cases

- References

Maintenance and Diagnostics

Whether flat roof are constructed of concrete or timber, they need to be laid to adequate falls and incorporate a vapour barrier.

The generally accepted minimum fall is 1 in 80, but the latest recommendation is 1 in 40 to make allowance for any inaccuracies on the site and possible deflection of the roof structure.

Ponding occur only when there is unevenness of the slab surfaces. Regular inspection should be carried out especially after a downpour. This allow for visual inspection of possible ponding area.

When ponding happen, immediate repair is needed. Apply a layer of screed so as to level the surface and take note of the fall, directing the flow of the water to the drainage area.

Maintenance

Use locally green-certified and good quality waterproofing membrane that requires minimal maintenance. However, it depends mainly on its exposure conditions and external factors. Regular

inspections and cleaning of roof surfaces should be carried out. Inspect roof area drains for

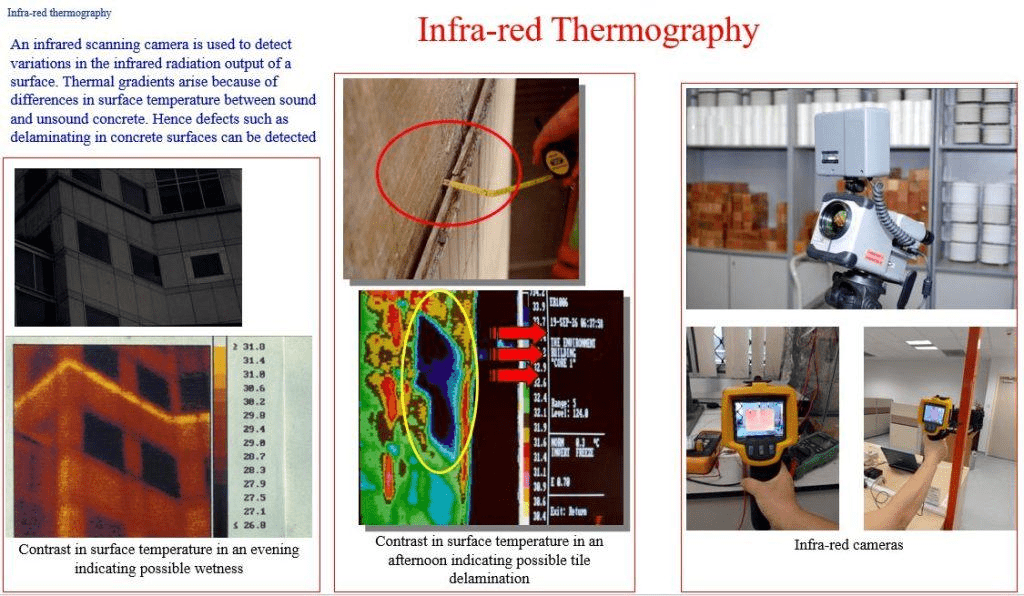

efficiency prior to water washing in accordance with BS 8221-1, SS 509-1 or equivalent. Use infrared thermographic surveys for diagnosis of roof membrane defects, which can identify moisture build-up within the structure. Diagnosis of waterproofing membrane failures leads to remedial actions if required. Actions can range from patch repairs to re-roofing. It can also include creating an effective slope or adding roof drains or taper systems.

Diagnostics of Defects (see also NDT)

Drone

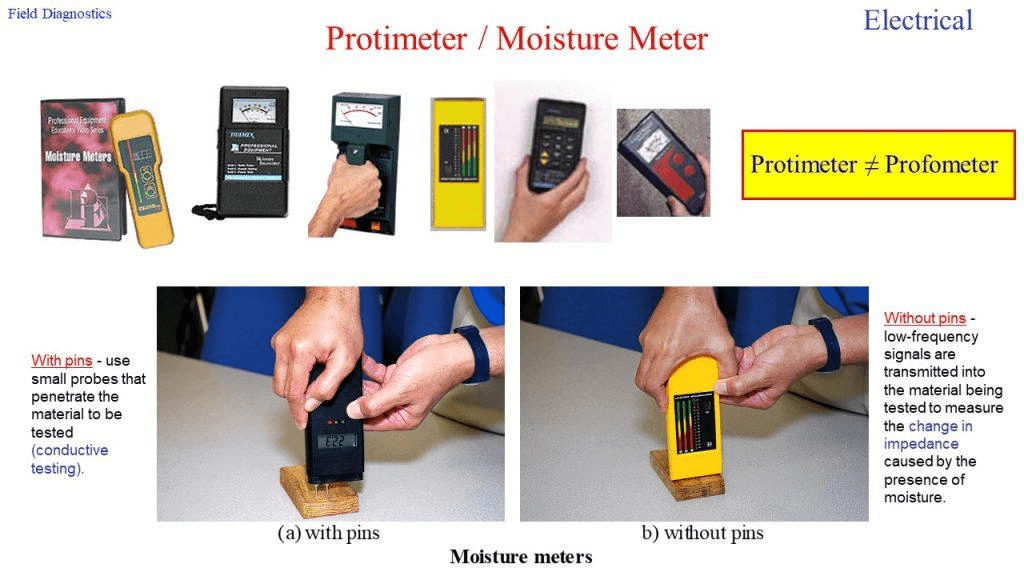

Moisture Meter Probes

To determine underlying suspect moisture. Moisture meter probes utilizing non-destructive technology. This meter is the ultimate investigative tool for detecting water on or beneath wood; roofing; plaster and brick; even below the waterproof covering of a felt roof.

No more unnecessary holes made by metal probes. Electric signals are transmitted to the surface from two scratch-proof, rubber electrodes which target the exact location of a leak. Three separate scales assure accurate readings for each surface material. Simply select a scale, hold the Moisture Encounter to the surface, and read directly from the meter.

Thermography

Thermography can be used to identify the position of cracks. A range of crack widths, representing mechanical damage, has been induced under controlled laboratory conditions. The method is based on the characteristics of heat flow phenomenon, in a conductive medium of specific geometry, which is intended to model predetermined boundary conditions.

The method is based on the characteristics of heat flow phenomenon, in a conductive medium of specific geometry, which is intended to model predetermined boundary conditions. Thermo tracer is an advanced equipment used in thermograph technology.

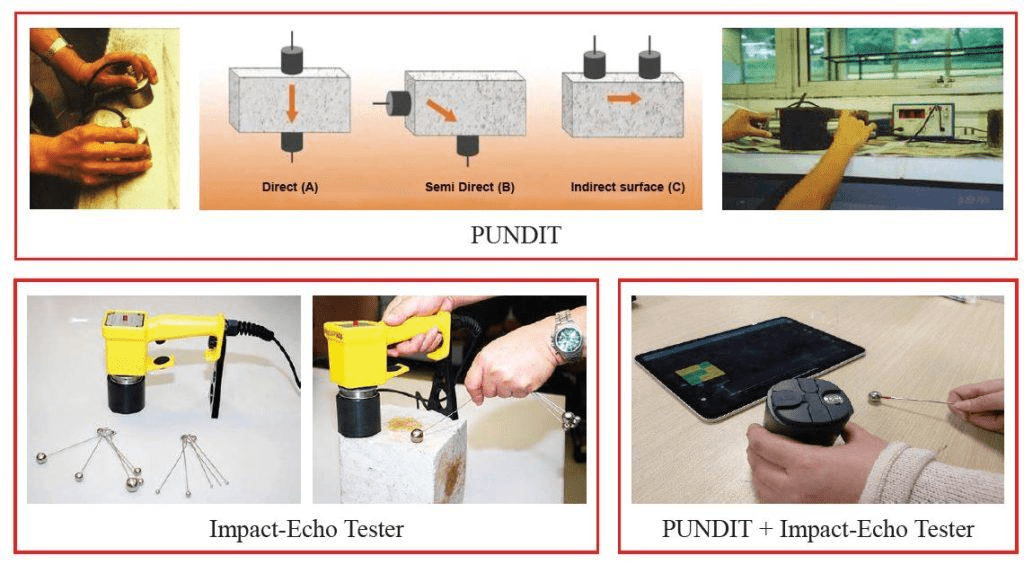

Ultrasonic Pulse Velocity (UPV)

UPV can identify non-homogeneous conditions such as voids, cracks and honeycombs using the optional hand-held terminal. This method can also be used to estimate the depth of cracks.

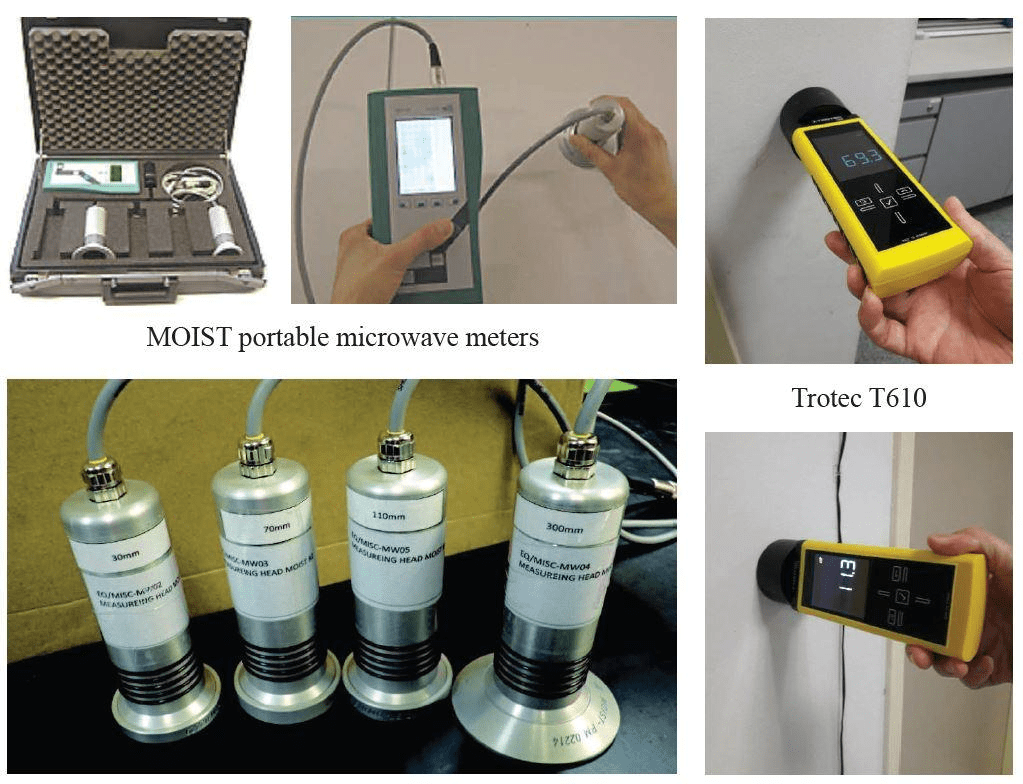

Microwave tomography is a technique to measure the moisture of various materials based on the relatively high dielectric constant of “water” in comparison to the dielectric properties of the material. An electrical field (microwave) is applied to the material, and the microwave induces oscillations of bipolar molecules (i.e., water). Water molecules will reflect and absorb an electrical field during oscillations. A higher electrical field reflected indicates higher water content.

The technique is non-destructive and applicable to wood, brickwork and concrete. The uniqueness of this technique is its ability to measure moisture content at various depths up to 110 mm, allowing the plotting of a 3-D contour of moisture content and facilitating the tracing of the water source.