Case 2

Navigation

- Introduction

- Causes of Defects

- Good Practices

- Standards

- Maintenance and Diagnostics

- Remedial

- Similar Cases

- References

Good Practices

Concrete

Ensure a good mix of dense concrete in order to improve durability. This has to be achieved at various stages in the process.

Design

- Specifying a dense concrete with minimum water-cement ratio.

- Ensure that the concrete mix is appropriate and to the specifications specified. Suitable grading of all suitable materials combined to provide the least amount of voids.

- Sufficient cover to reinforcement must be maintained.

Material

- Select appropriate concrete, reinforcement for concrete work.

Construction

- Ensure that the concrete mix is appropriate for construction and to the specifications specified. Mix concrete properly on site. Use a container, not a shovel, to measure each part of materials used in the mix. Add only enough water to obtain an even, workable mix.

- If the concrete is ready mix, it shall comply with SS 289.

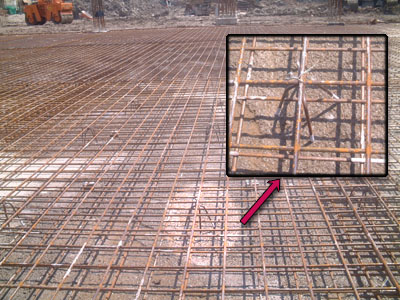

- Reinforcements should be laid properly under supervision of consultant engineers and removal of rust and mill scale is important before embedment.

- They can be protected further by using the following methods:

- use of non-metallic coatings such as epoxy coatings or cement based coatings

- use of metallic coatings such as Zinc and Nickel

- Cathodic protection

- use of corrosion inhibitors

- use of corrosion resistance reinforcement (eg. stainless steel)

- Ensure thorough compaction of the concrete during placement.

Quality Control

- Check for quality of concrete before placing. e.g. water cement ratio, slump test, etc.

- Check for correct concrete cover thickness.