Case 2

- Introduction

- Causes of Defects

- Good Practices

- Standards

- Maintenance and Diagnostics

- Remedial

- Similar Cases

- References

Remedial (see also Remedial)

1. Repair of structural crack lines (Procedure of Surface Repair)

Surface repairs can be done on the floor slab if there are no signs of water seepage from underneath or widening of gap with time.

2. Polymer Modified Cementitious Grouting

This can be applied on the crack so that the final appearance of concrete structure closely resembles the concrete being repaired, in respect of strength and long term movement. Its characteristics are improved with regards to bonding, flexibility and time within which strength is gained.

3. Patching (Procedure of Patching)

This method is used to rehabilitate corrosion-damaged infrastructure, where the application of waterproofing membranes prevents, or at least retard, the ingress of chlorides to the reinforcement. However, when the chloride content in the concrete in contact with the rebars equals or exceeds the corrosion threshold, membranes will have no significant impact on reducing the level of corrosion.

The patching method is the most common repair method for minor concrete defects such as surface spalls. Two types of materials are commonly used for patching up by hand:

Cementitious mortars such as cement mortar and polyester-modified cementitious mortar.

Resin-based mortars such as epoxy resin mortar and polyester resin mortar.

4. Repair using epoxy injection (Procedure of Epoxy Injection)

One of the most versatile, crack repair method is epoxy injection.

Repair using Conventional Patching Method

Patching of small defective areas should be properly. However, the area of concrete where spalling occurs should not be porous to reap maximum advantage of this method.

Other protection methods for rebars

| Protective System | System description | Comments | |

| Benefits | Concrete | ||

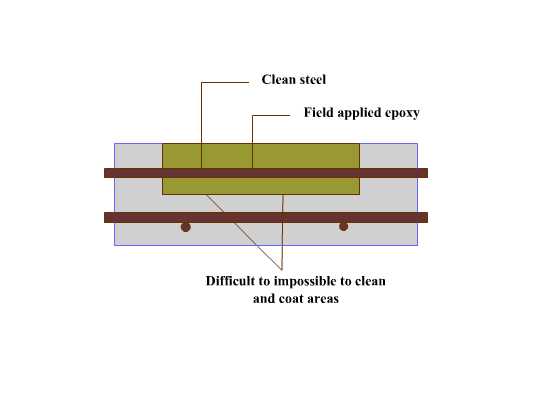

Epoxy Bar Coating Epoxy Bar Coating | Two components epoxy coating field applied over cleaned reinforcing steel surface. Epoxy is brushed onto the bar. | Provides impermeable dielectric barrier, isolates the steel from contact with oxygen, moisture and chlorides. | 1. Very difficult to achieve 100% coverage. Intersections and backsides of rebar create almost impossible access.

2. Lower bond with repair material. 3. Isolates the steel from high pH material 4. Contaminates adjacent concrete surfaces with epoxy. |

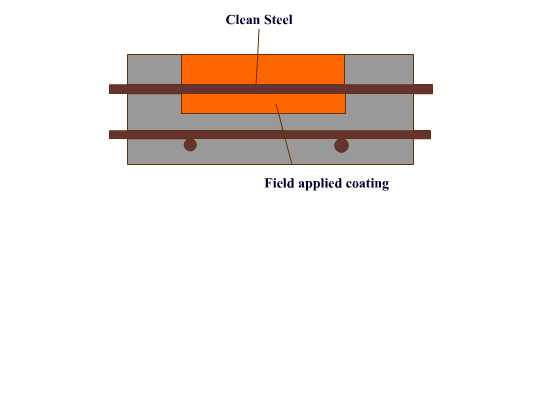

Cement based Coating | Alkaline cement-based polymer-modified bar coating.Applied to the bar with a brush. | 1. Maintains the high alkalinity environment surrounding the bar.

2. Does not decrease the repair material bond to bar. | The coatings are susceptible to deterioration due to the continued chloride ingress. |

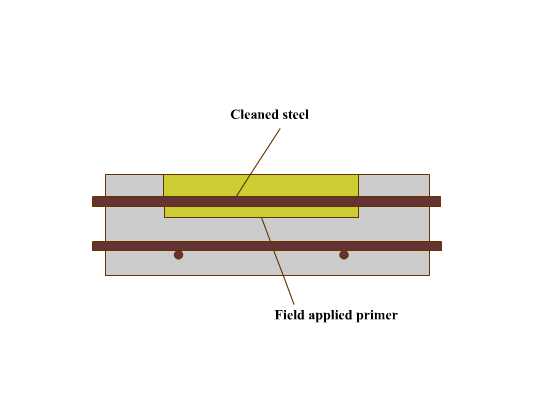

Sacrificial Metallic Coating | Sacrificial metallic coating (galvanic anode method of cathodic protection ) is usually a zinc rich primer. | This coating improves the corrosion resistance of the coated steel in the repair area. Corrosion products of the sacrificial material are not as expansive and detrimental to the repair material as mild steel corrosion products. | 1. Their effectiveness in preventing corrosion of the unexposed steel in chloride contaminated existing concrete adjacent to the repair is not yet known.

2. Zinc-rich primer protection has a high consumption (corrosion) rate. |

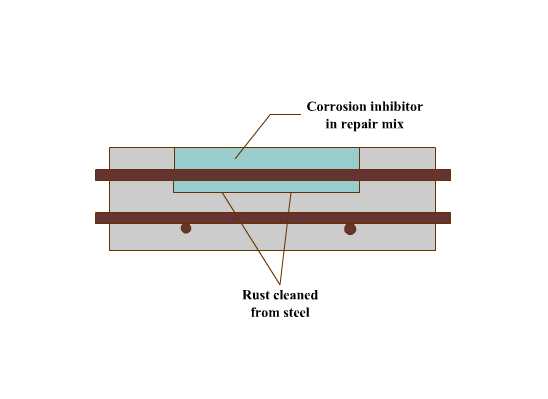

Corrosion Inhibitor in Repair Material | Calcium nitrite inhibitor added to repair material mix. | 1. Delays the corrosion of embedded steel.

2. Very easy to use. | Calcium nitrite is effective in maintaining passivity only if present in sufficiently high concentration around the rebars.

The admixture tends to be dispersed in the repair and adjacent portions of the existing concrete rather than at repair/steel interface. |