Case 2

- Introduction

- Causes of Defects

- Good Practices

- Standards

- Maintenance and Diagnostics

- Remedial

- Similar Cases

- References

Remedial (see also Remedial)

Crack Repair Method

Repair Using Polyurethane (PU) Grouting

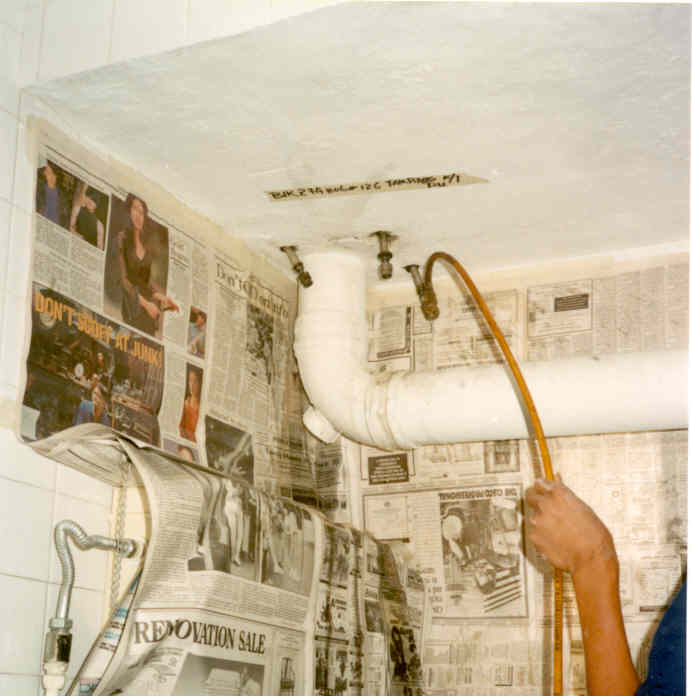

The major cracks or localized porous concrete can be repaired by PU grouting. The injection could be carried out at the passive side or active side of the slab as illustrated in the picture and the video.

Polyurethane (PU) grouting is specially designed for providing water control in static joints or cracks in concrete structures. The grout material, when mixed with a certain amount of accelerator, will react with water or moisture and expand to form a tough, closed-cell rubber that is essentially unaffected by corrosive environment.

Polyurethanes are products of the petrochemical industry. They are very durable when exposed to external conditions and retain their gloss well. They can be obtained as elastomers, solid and rigid materials or flexible coatings. Major cracks or localized porous concrete can be repaired by this method.

In the application, PU reacts upon with the water in the slab and expands its volume and thus fills the cracks or pores in the slab. Therefore, it acts as a sealer over the cracks. The repairing process can be completed within half a day. Accelerator agents can be used to speed up the setting time of the grout. A finishing coat may be applied after the remedial work is completed.

Seal up the leakage

It is possible to use polyurethene grout injection. It will seal up the holes and cracks in the concrete as well as seal up the passage of water from the soil.

(1) Hack to expose the concrete around the area that is affected to look for cracks of defective concrete.

(2) Drill holes approximately a foot apart along the crack to install the packer.

(3) Wet the area around the defects so that it is easy to clean when the excess chemical is dried.

(4) Pump the chemical in the concrete through the packer until it overflows.

(5) Allow one hour for drying up before removing excessive chemical with scraper and patch up the holes with cement mortar.

Repair using epoxy injection

One of the most versatile, crack repair method is epoxy injection. This method has been successfully used in buildings, bridges, dams etc., due to following characteristics:

– Outstanding adhesive qualities to materials such as concrete and steel

– Resistance to a wide range of acids and alkalis and other chemicals, except acids such as nitric which have high oxidizing characteristics

– Rather vulnerable to organic solvents

– Low shrinkage when the compound course and changes from the liquid to the solid state

– High coefficient of thermal movement compared with concrete

– High compressive, tensile and flexural strength

– Appreciable loss of strength at temperatures over about 80oC

– High rate of gain of strength which can be varied to suit the particular application

The site conditions under which the resin will be applied must be stated to the formulator. Unless specially formulated, most epoxide resins must be applied to dry surfaces and the ambient air temperature and relative humidity during application must be kept within fairly narrow limit.