Case 2

- Introduction

- Causes of Defects

- Good Practices

- Standards

- Maintenance and Diagnostics

- Remedial

- Similar Cases

- References

Maintenance and Diagnostics

Regular inspections should be carried out of wet areas, especially at vulnerable interfaces/joints between

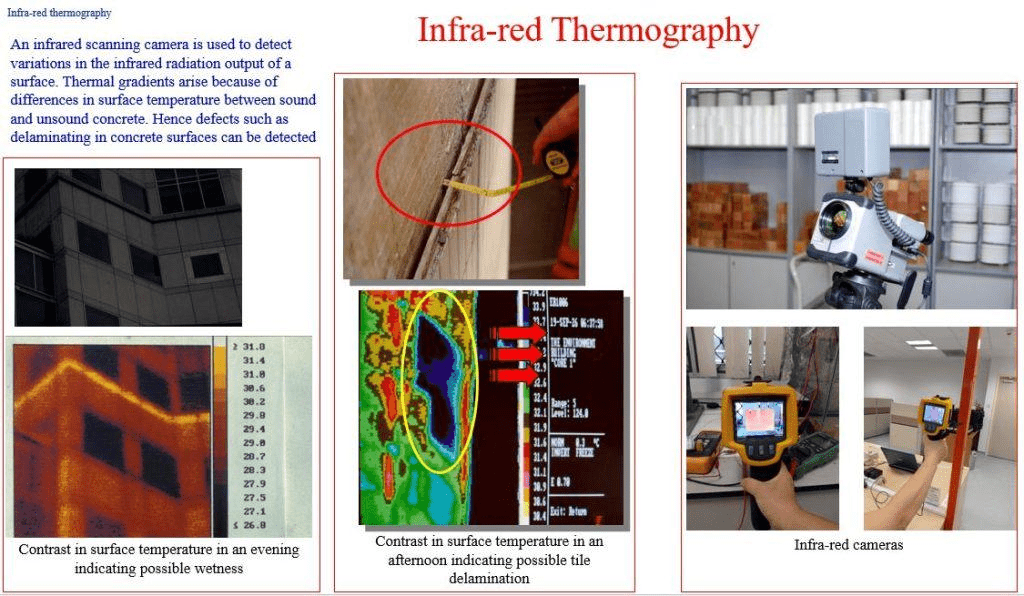

different materials. Use non-destructive testing (NDT) in this regard. Water leakage can be identified using thermography images in accordance with BS ISO 10880 or by using a moisture meter. Repair work can be done using polyurethane (PU) grouting/injection for local seepages. For more severe incidents, laying of new waterproof screed is strongly recommended.

Maintenance

Regular inspections should be carried out periodically at regular intervals to detect the defects and to take remedial action to keep the structure in good condition. Discharge pipe system should be kept clean regularly in order to maintain maximum efficiency.

Care should be taken when using the chemical descaling agents which are often of a corrosive nature. Therefore, it is important to clearly identify the materials used in the system before using the chemicals.

The following solutions are recommended for different types of deposits:

| Type of scale | Cleaning method | Possible locations |

| Deposits due to misuse of the discharge system | Blockage due to large object or compacted masses such as toilet paper and sanitary towels can be loosened by rodding. | Discharge pipe |

| Lime scale | Periodic de-scaling using a suitable inhibited acid based cleaners (see Table 15 in BS 5572) | Discharge stack and pipes from urinals |

| Accumulation of greases and soap residuals | This can partially be removed by use of a plunger, but most effective way is by flushing the system with a strong solution of soda crystals dissolve in hot water (see Table 15 in BS 5572). | Discharge pipes from sinks or wash basins |

- Periodic inspection and tests are advisable to ascertain any other defects such as water leakages, wear and tear or negligence.

- The following instruments and techniques can be used to detect water leakages in sanitary fittings and pipes.

Diagnostics of Defect (see also NDT)

This instrument is useful when services are concealed. There have been many cases of collapse of large area of false ceiling, due to weight of accumulation of water or condensate. Regular inspection using a fibrescope/borescope could prevent such accidents.

A fibrescope or a flexible borescope is a flexible optical inspection device that consists of fibre optic bundles with an eyepiece at one end and a lens at the other.

A fibrescope usually comes in two bundles: (i) a fibre optic light bundle that is for illuminating the object to be investigated, and (ii) a fibre optic image bundle to relay the image to the eyepiece. It allows a direct visual inspection for an otherwise inaccessible part, as observations of remote, difficult-to-reach areas can be made through a video monitor with high-resolution images. The flexible fibres allow it to be manoevred in hard-to-reach or inaccessible areas.

It is often used to verify findings from other tests, such as infrared thermography or impact-echo testing.

Common applications include:

– Inspection of connecting condition behind the external cladding wall of a building.

– Inspection of defects on concrete surface(s) in a deep and narrow gap.

– Determination of corrosion condition of steel tendon(s) inside post-tensioning ducts of pre-stressed structural member(s).

– Investigation of service pipes, ducts and other inaccessible areas.

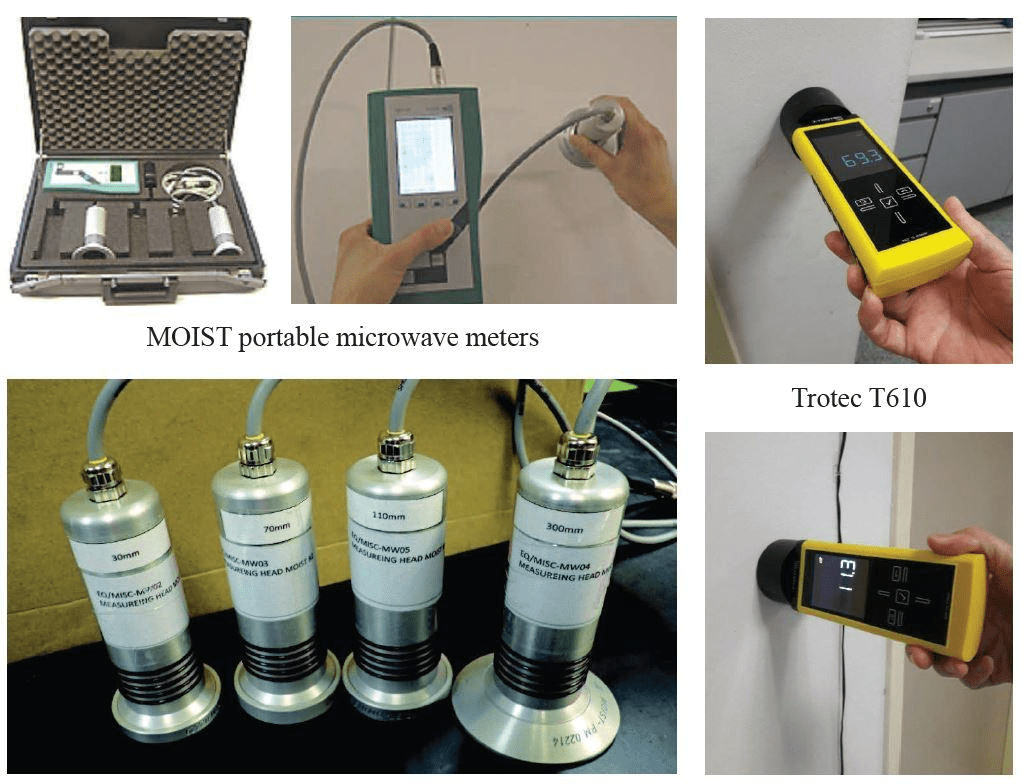

Microwave tomography is a technique to measure the moisture of various materials based on the relatively high dielectric constant of “water” in comparison to the dielectric properties of the material. An electrical field (microwave) is applied to the material, and the microwave induces oscillations of bipolar molecules (i.e., water). Water molecules will reflect and absorb an electrical field during oscillations. A higher electrical field reflected indicates higher water content.

The technique is non-destructive and applicable to wood, brickwork and concrete. The uniqueness of this technique is its ability to measure moisture content at various depths up to 110 mm, allowing the plotting of a 3-D contour of moisture content and facilitating the tracing of the water source.

Thermography can be used to identify the position of water leakages. The method is based on the characteristics of heat flow phenomenon, in a conductive medium of specific geometry, which is intended to model predetermined boundary conditions. Thermo tracer is an advanced equipment used in thermography technology.

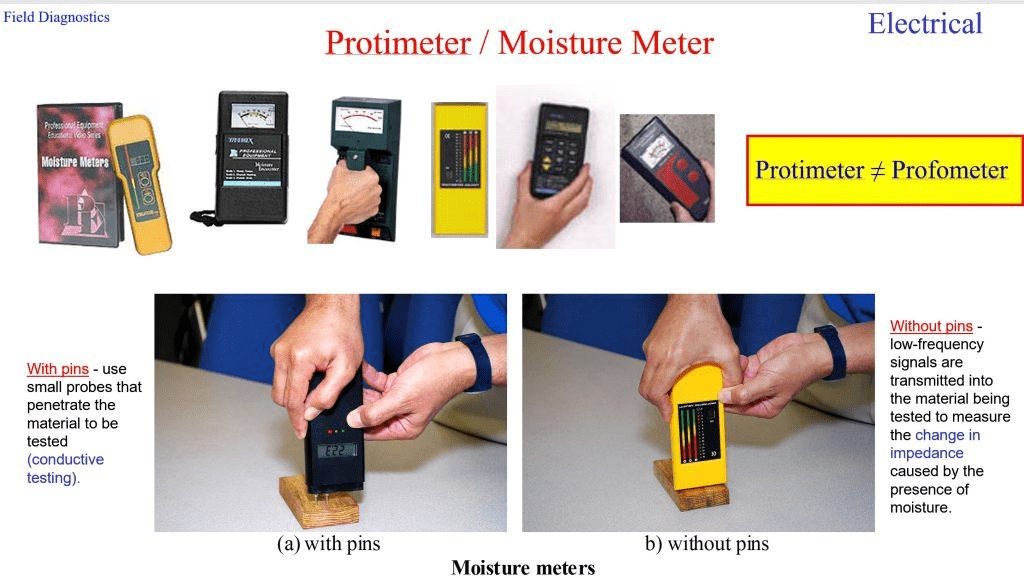

Protimeter / Moisture Meter

Moisture meter is used to determine the presence of moisture [7]. Moisture readings can be taken within masonry walls, dry walls, insulation, concrete members, roofing, wood construction, and other building components.