Case 3

- Introduction

- Causes of Defects

- Good Practices

- Standards

- Maintenance and Diagnostics

- Remedial

- Similar Cases

- References

Remedial (see also Remedial)

Remediate any leakage by removal of screed, clearing all loose particles and re-application of waterproofing. Localised porous concrete can be repaired by polyurethane (PU) grouting by injecting into either the passive or active side of the slab/wall. Repair leakage at cracks by injecting PU grout, or the Flood Infusion Method.

Repairing using crystallisation

Crystallisation method can also be used to stop water seepage. These are silicone based chemicals and when they come into contact with water, they will seal up the cracks. They are reactive pore fillers which penetrates into capillary tracts of concrete to react with free lime and water to form crystalline chain which blocks up the capillary and makes concrete water-tight.

Advantage:

– The crystalline formed in the concrete will be able to improve the integrity of concrete by sealing up pores to prevent penetration of water and other chemical. Also it is independent of surface adhesion so it can resist high hydrostatic pressure.

– Normally, the crystallization chemical acts as a catalyst so it will last much longer than other injection material. Due to the same reason, it creates a automatic crack closure effect as long as water is present.

Limitation:

– This method can only be used to seal cracks up to a limited depth.

Re-waterproofing and sealing

The following are the steps in this method:

– Repair area should be cleaned with high-pressure water jet, before starting the repair.

– Chisel grooves along major crack lines and along the suspected leaking areas.

– Apply a layer of crystal slurry on the floor. It will penetrate deeply into the capillary pores of the concrete, sealing the pores and shrinkage cracks by crystallization permanently. Allow the chemical to cure.

– Plug grooves with water seal. When it cures, it expands and locks the affected areas making a watertight seal.

– A coating of Cement Strengtheners Polymer can be applied to give a stronger bonding capability. With its waterproofing property, it is able to act as a waterproofing membrane which locks the infiltrated areas from further seepages. Allow the chemical proceedings to cure.

– Water repellent may be sprayed on the slab in order to further strengthen the waterproofing ability.

Repair Using Polyurethane (PU) Grouting

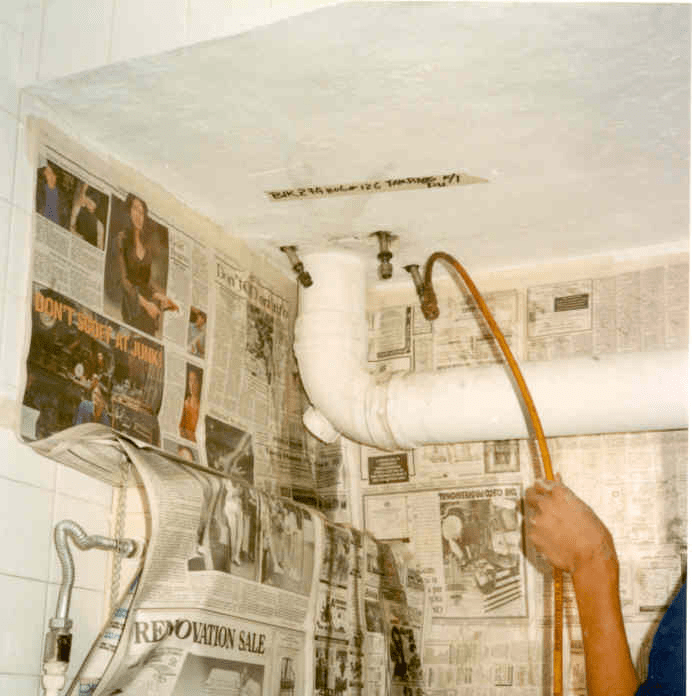

The major cracks or localized porous concrete can be repaired by PU grouting. The injection could be carried out at the passive side or active side of the slab as illustrated in the picture and the video.

Polyurethane (PU) grouting is specially designed for providing water control in static joints or cracks in concrete structures. The grout material, when mixed with a certain amount of accelerator, will react with water or moisture and expand to form a tough, closed-cell rubber that is essentially unaffected by corrosive environment.

Polyurethanes are products of the petrochemical industry. They are very durable when exposed to external conditions and retain their gloss well. They can be obtained as elastomers, solid and rigid materials or flexible coatings. Major cracks or localized porous concrete can be repaired by this method.

In the application, PU reacts upon with the water in the slab and expands its volume and thus fills the cracks or pores in the slab. Therefore, it acts as a sealer over the cracks. The repairing process can be completed within half a day. Accelerator agents can be used to speed up the setting time of the grout. A finishing coat may be applied after the remedial work is completed.

Seal up the leakage

It is possible to use polyurethene grout injection. It will seal up the holes and cracks in the concrete as well as seal up the passage of water from the soil.

(1) Hack to expose the concrete around the area that is affected to look for cracks of defective concrete.

(2) Drill holes approximately a foot apart along the crack to install the packer.

(3) Wet the area around the defects so that it is easy to clean when the excess chemical is dried.

(4) Pump the chemical in the concrete through the packer until it overflows.

(5) Allow one hour for drying up before removing excessive chemical with scraper and patch up the holes with cement mortar.