Case 2 – Concrete Spalling

- Introduction

- Causes of Defects

- Good Practices

- Standards

- Maintenance and Diagnostics

- Remedial

- Similar Cases

- References

Concrete Spalling

Introduction

Type of Building: Commercial

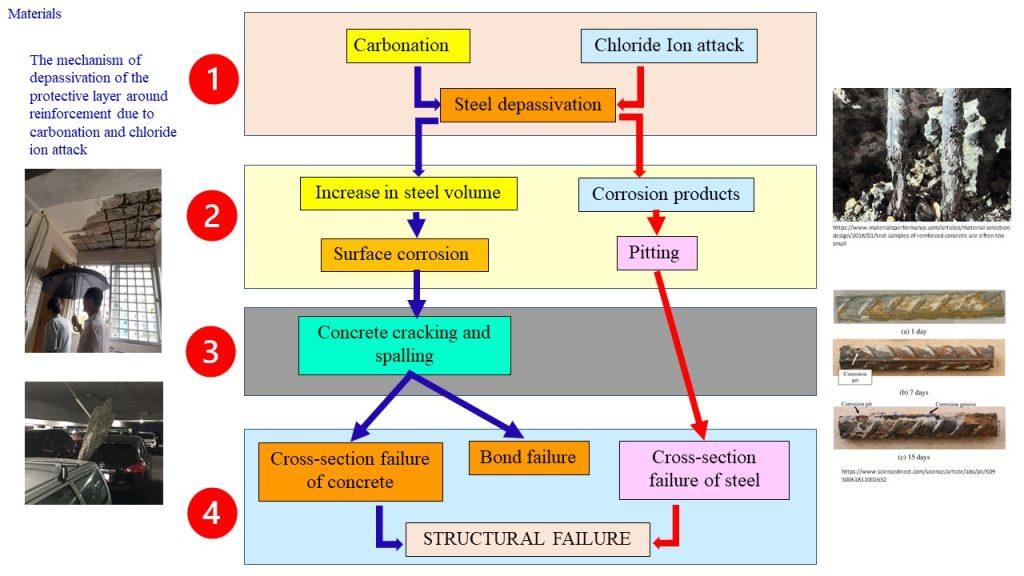

The ceiling had spalled over multiple areas and they are located near to some of the previous repaired spots, as seen by the injection markings. Reinforcement bars revealed are corroded and there were also efflorescence stains appearing around the spalled areas, indicating some recurring water leakage problem.

Corrosion of the steel produces iron oxides and hydroxides, which have larger volume than its original metallic iron volume. This increase in volume (approximately 5 times) develops tensile bursting stresses around reinforcement bars. As concrete is weak in tension, these stresses will cause cracking in concrete.

Corrosion is an electrochemical process, in which the following reactions are taking place to produce rust. Once rust film forms, its porous surface acts as a reservoir for liquids, which in turn causes further corrosion. If this process is not arrested, it would continue until the iron is entirely consumed by corrosion. In this case, corrosion has been spread until the surface (anode zone) is entirely damaged.