Case 2 – Concrete Spalling

- Introduction

- Causes of Defects

- Good Practices

- Standards

- Maintenance and Diagnostics

- Remedial

- Similar Cases

- References

Maintenance and Diagnostics

It is known that good quality concrete does not require extensive maintenance. However, due to external factors, it may develop some defects even before reaching its design life. Therefore, regular inspections should be carried out methodically at regular intervals to detect defects. A suitable checklist could be used to ensure comprehensive checks. Proper diagnosis of these defects is very important to select correct corrective maintenance. The following instruments and techniques can be useful in defect diagnostic process.

Regular inspection should be carried out in accordance with BS 8210 to identify defects and ensure repair work is carried out before associated damage can occur. Testing of concrete via depth of carbonation

should be carried out to identify possible corrosion of rebar in accordance with BS 1881-210 or via the

phenolphthalein method in accordance with BS EN 14630 or equivalent. Damaged concrete due to

corrosion of reinforced steel should be repaired and protected in accordance with BS EN 1504-9 or equivalent.

Diagnostics of Defect (see also NDT)

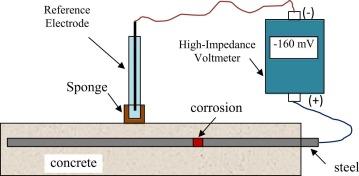

Half Cell Potential Measurement

The main application of Half cell measurement is to evaluate the probability of corrosion of the steel reinforcement embedded in the concrete members. This is measured in relation to the potential value readings.

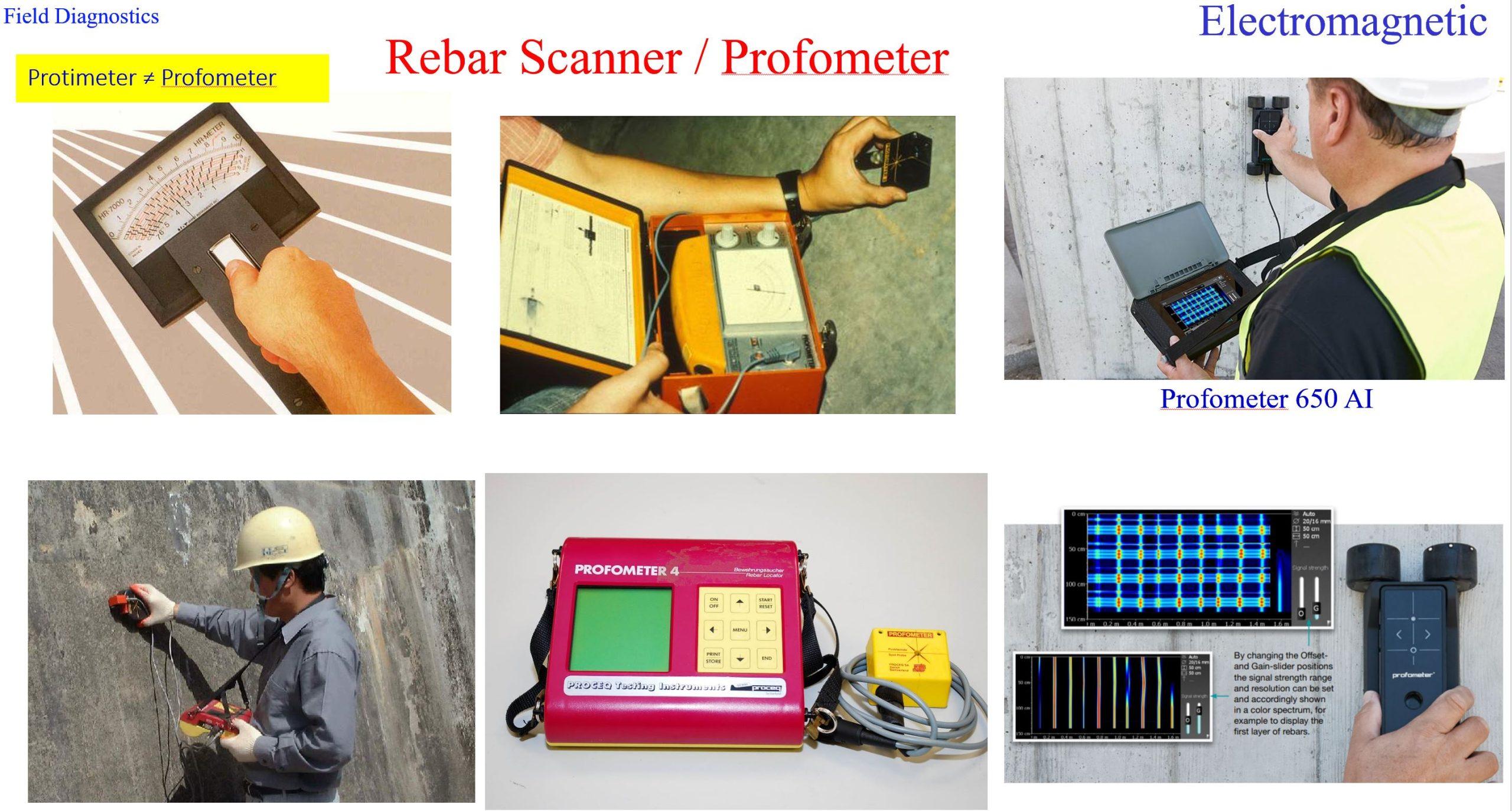

Profometer (Covermeter) – rebar scanner

Profometers (covermeters), based on the principles of electromagnetism, are use to locate and to measure the depth of rebar (concrete cover).

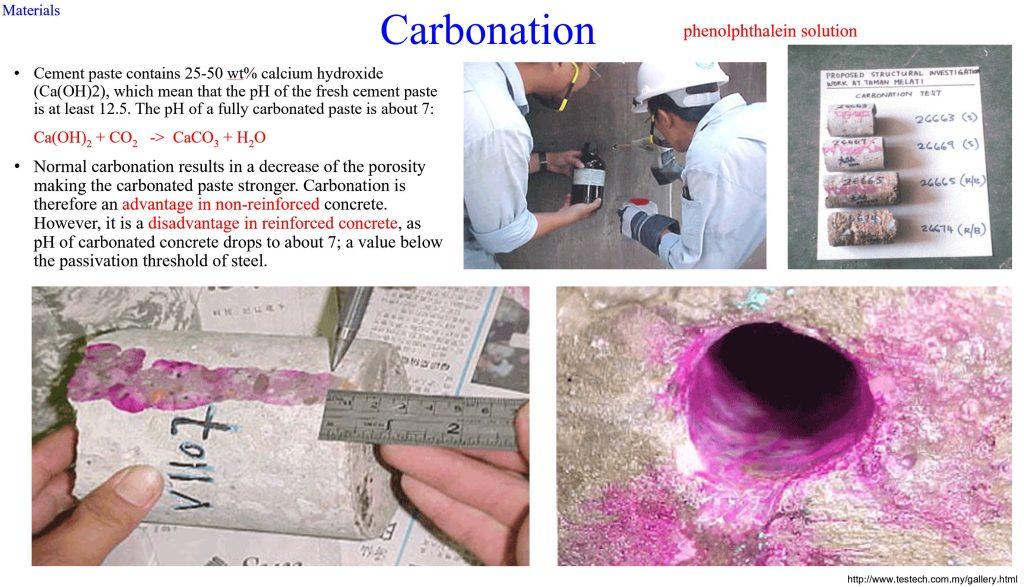

Carbonation Test

The depth of carbonation in the freshly exposed surfaces of concrete can be determined by spraying with phenolphthalein indicator solution. In the case that pink colour appears, it means that the concrete still retains its alkaline nature and carbonation is minimal.

This test can be done in the laboratories as well as on sites.

Spray concrete surface with phenolphthalein indicator, which registers a strong pink colour if the concrete retains its alkalinity.

Depth of carbonation is the location of the carbonation front and its proximity to the bars.

If the average carbonation depth approaches the average cover depth, more steel will start to corrode.

Eddy Current Test

Eddy Current NDT is an inductive technique which employs a probe (coil with a AC current) placed close to the inspected material. When an AC current flows in a coil in close proximity to a conducting surface the magnetic field of the coil will induce circulating (eddy) currents in that surface.

The primary flux in the Figure above induces eddy currents in the material which give rise to a secondary flux. The secondary flux is then coupled back to the coil which affects its impedance. Thus the magnitude and phase of the eddy currents will affect the loading on the coil and thus its impedance. If a discontinuity (defect) is present in the material the eddy current density will be changed which can be observed as a change in coil impedance.

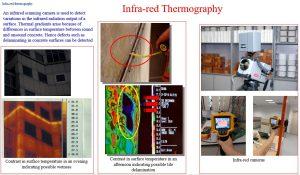

Thermography

Thermography can be used to identify the position of cracks. A range of crack widths, representing mechanical damage, has been induced under controlled laboratory conditions.

The method is based on the characteristics of heat flow phenomenon, in a conductive medium of specific geometry, which is intended to model predetermined boundary conditions. Thermo tracer is an advanced equipment used in thermography technology.