Case 2 – Concrete Spalling

- Introduction

- Causes of Defects

- Good Practices

- Standards

- Maintenance and Diagnostics

- Remedial

- Similar Cases

- References

Cause of Defects

Concrete may be carbonated by the carbon dioxide from vehicle exhaust. Thus, the alkaline protective environment of the concrete is removed and corrosion begins. Due to the increase in volume of rebars from the formation of rust, corrosion of rebars and spalling of concrete may result.

Honeycombs in the concrete structure or lack of concrete cover may accelerate this carbonation process.

Concrete may be carbonated by the carbon dioxide from vehicle exhaust. Thus, the alkaline protective environment of the concrete is removed and corrosion begins. Due to the increase in volume of rebars from the formation of rust, corrosion of rebars and spalling of concrete may result.

Honeycombs in the concrete structure or lack of concrete cover may accelerate this carbonation process.

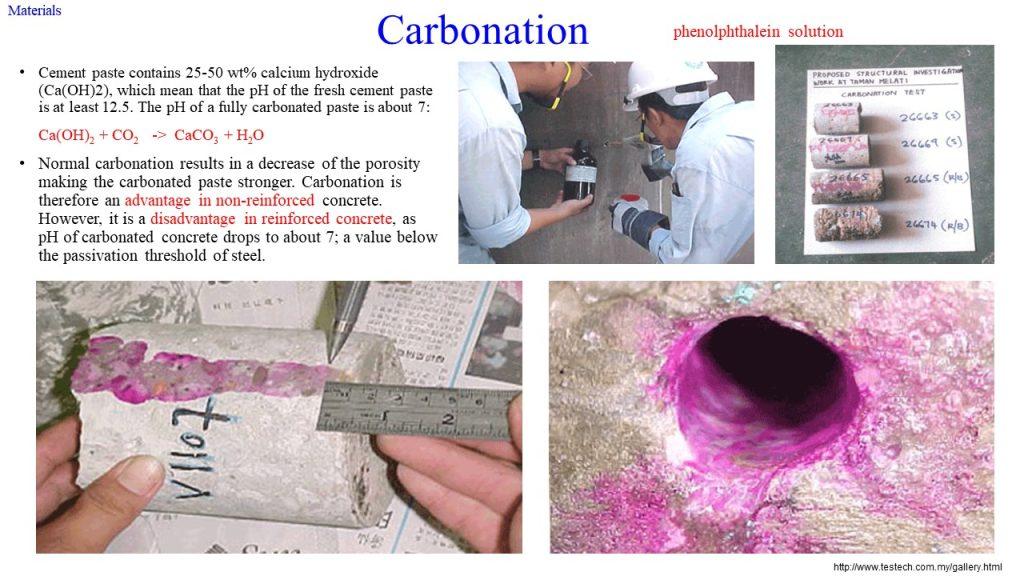

The high alkalinity of Ca(OH)2 is good in the case of preventing reinforcement corrosion, as the calcium hydroxide solution forms a protective passivating layer around the reinforcement with an alkaline environment of pH up to 13. This alkalinity, however, can be destroyed by carbonation, where

Ca(OH)2 + CO2 → CaCO3 + H2O

or through the addition of chloride ions, which could enter concrete either (i) as an added component during mixing, deliberately included as an admixture, or (ii) as an external agent, e.g., seawater or breeze entering the already set concrete.