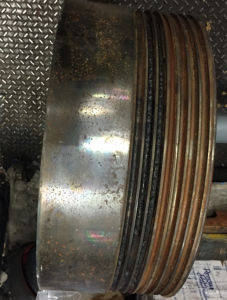

Wearing drive sheave grooves of traction machine

- Description of defect

During operation, when ropes or belts are under tensioned, they will slip into the groove of the sheaves. As the drives continuously rotating, the slipping ropes or belts will erode the sheave grooves.

Regular maintenance is very crucial in preventing wearing grooves. Faulty during installation of the sheaves also led to wearing sheave grooves.

Bearings must be properly installed in order to ensure the sheave and the shaft is properly engaged. Failure to install the sheave bearing will cause the component to wobble and vibration which can result in premature sheave wear.

- Causes

- Ropes or belts are under tensioned

- improper installation of bearing sheaves

Worn elevator drive sheave [13]

- Diagnostic/testing method

The condition of the traction sheave and the sheave diameter shall be inspected while cut off the power. Inspection for alignment, installation and ensuring the ropes and belts are in adequate tension will hinder defects on traction sheave. With power on, the running condition of traction machine shall be observed, and record if there is any unusual noises (SS550).

Groove gauges is used to check drive sheave grooves [14]

- Good practices

Grooves profile need to be inspected to ensure that it fits between the ropes and the sheave. Tools with magnetic standards and a straight edge is used to visually check if the grooves on the sheaves are wearing uniformly.

Technicians also need to ensure the sheaves are free from contaminants such as sand and dust that can erode the sheaves. Hence, regular sheave cleaning will minimize sheave grooves wear.

- Corrections

Worn sheaves can be regroove or replace to avoid premature failure to the hoisting ropes [13].

Method of regrooving sheaves [15]