Façade Coatings

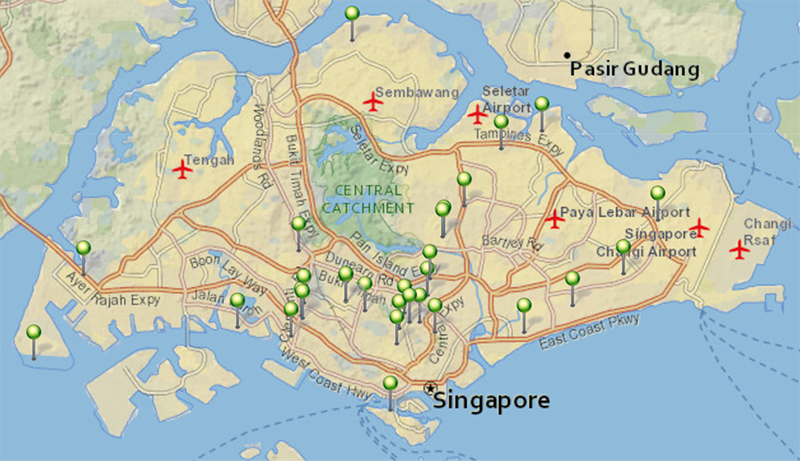

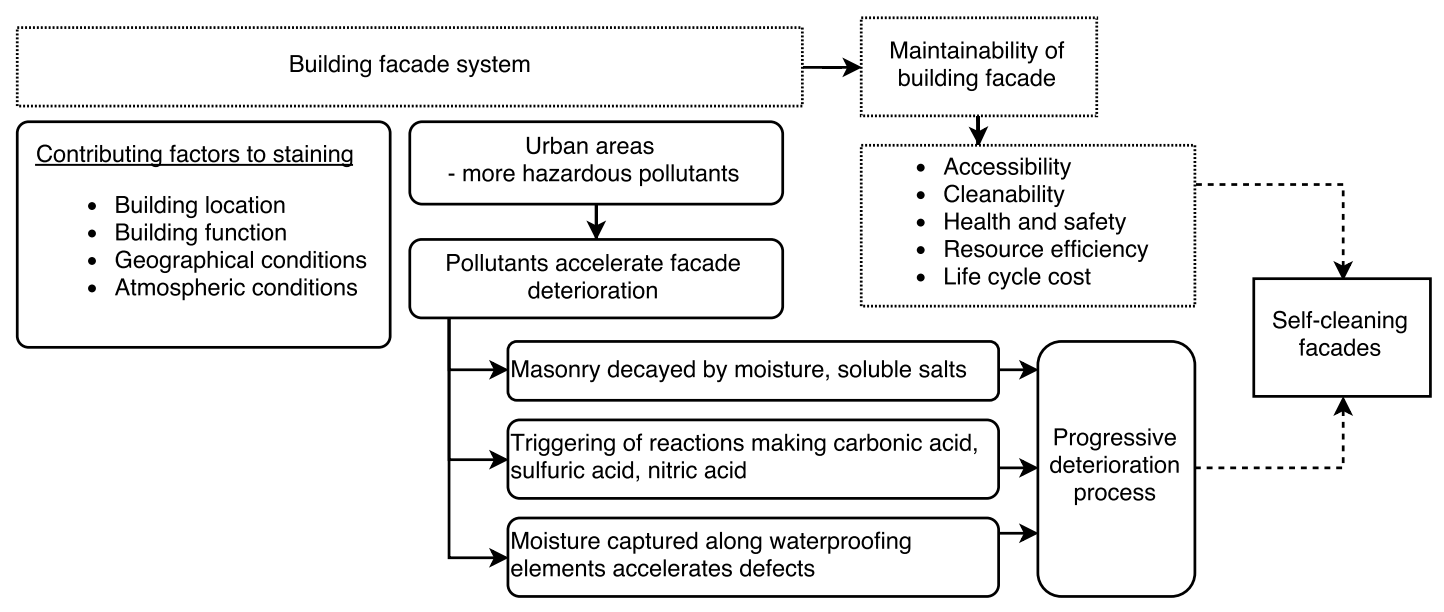

The facade, which accounts to be the largest building element, is important for both architecture and engineering point of view. Not only it insulates the entire building and its occupants from external environment such as weather, pollution and noise, but it also sets the aesthetics and identity for the rest of the building and it also directly impacts on the building’s energy efficiency. The building facade faces a myriad of external stresses in hot-humid tropical coastal and highly dense condition of Singapore which aggravate the cost of upkeep of facades as well as the vulnerability of facades to defects. By that reason building professionals are especially keen on technologies and techniques for higher maintainability of facades which ensures easier maintenance. Such approaches include self-cleaning facades and cool coating systems.

It is long been established that paints and coatings hold much more importance to building facades than only its appearance sake. It provides a degree of protection from external extremities resulting in corrosion and damages. Especially in tropical climates such as in Singapore, façade coatings are exposed to severe environmental influences such as temperature variations, moisture, rain and aggressive media such as strong cleaning agents, biological residues (from insects and birds) and acid rains.

Therefore, façade coatings need to withstand such external stresses and the durability of the coating system itself should be measured and made aware of for informed design decisions to be made. Moreover, façade cleaning is a cause of considerable trouble, high use of resources such as energy, water and chemicals leading to high costs [4].

The façade maintainability framework shows the requirement to seek new technologies as façade protective systems for buildings in the tropics.

External stresses affecting façade coating systems

The external stresses that the building envelope gets subjected to needs to be considered for in evaluating self-cleaning facades. Examples will include rain, relative humidity, wind, pollutants and solar radiation. These stresses either acts as a staining agent or a driving force for staining.

Rain and Relative Humidity

Rain is responsible for many of the destructive mechanisms that a building will experience during their lifetime [1]. Examples include corrosion, leaching, efflorescence and water penetration leads to deterioration of the facade. Rainwater starts the process of staining the façade, the movement of water could either clean the façade or leave deposits of dirt of the surfaces. Water is also crucial for the efflorescence and the biological staining. Acid rain also needs to be considered but will be covered in the pollution part of this chapter.

In Singapore the monthly rainfall ranges from 158.3 to 288.2 mm monthly based on the National Environment Agency statistics [2]. Combined with the high relative humidity (64 to 97 %) and strong ultraviolet radiation makes Singapore a harsh climate for coatings, sealants and other façade materials.

Wind

The building facade position relative to the normal wind direction will also need to be considered [1]. The main reason is due to the change of direction of the fall of raindrops, instead of being vertical the rain drop might fall horizontally on to the façade if the wind strength is sufficiently strong enough.

Pollutants

World Health Organization Air Quality Guidelines (WHO AQGs) guidelines are used in Singapore [3]. Singapore’s air quality is better than many other cities in Asia but during the Haze period August – October the pollutant standard index (PSI) can rise above 250.

The common types of non-biological pollutants in Singapore are listed below in Table.

Common non-biological pollutants in Singapore (Chew, 2004)

| Pollutants | Examples | Size | Sources | Possible Effects |

| Aerosols | Sulphur dioxide | Gaseous | Burning of fuels | Formation of acid rain. Reaction with water and other materials from sulphates and chlorides, causing destruction to façade materials. |

| Soot or black | Smoke from tobacco, coal, fuel oil | <1μm | Imperfect combustion | Transported by air and deposited on facades, causing stains. |

| Coarse particulate matter | Ash, dust, mineral dust | >1μm | Unburnt fuel and dust | Transported by air for short distances and deposited on horizontal or sloping surfaces to form stains. |

The climate of Singapore is highly conducive for biological pollutants and needs to be considered as staining agents [1]. Plant groups such as algae, fungi, mosses, ferns and figs are qualified as staining agents. In a high rise city, such as Singapore, algae have gotten the most attention due to the cost of removing the stains caused. Excretion from animals, such as pigeons and mynahs that could stain the facade should also be taking into account.

Solar radiation

The impact of the solar radiation has to be considered, both the affect the UV-Light also known as UV-degradation of sealants, coatings and other polymeric products [1]. The photo tendering should also be acknowledged as a stress on the surface of the façade.

In Singapore the average number of sun hours is about 2,064 a year, which is about half of the maximum possible time [2].

International Standards

| Standard number and year | Title of standard | Description |

| ISO 22196: 2011 | Measurement of antibacterial activity on plastics and other non-porous surfaces | Evaluates the antibacterial activity of antibacterial-treated plastics, and other non-porous, surfaces of products (antibacterial activity value) |

| ISO 22197-1:2007 | Fine ceramics (advanced ceramics, advanced technical ceramics) — Test method for air-purification performance of semiconducting photocatalytic materials — Part 1: Removal of nitric oxide | Air purification effect

Nitric oxide removal

|

| ISO 22197-2: 2011 | Fine ceramics (advanced ceramics, advanced technical ceramics) — Test method for air-purification performance of semiconducting photocatalytic materials — Part 2: Removal of acetaldehyde | Acetaldehyde removal |

| ISO 22197-3: 2011 | Fine ceramics (advanced ceramics, advanced technical ceramics) — Test method for air-purification performance of semiconducting photocatalytic materials — Part 3: Removal of toluene | Toluene removal |

| ISO 27447: 2009 | Fine ceramics (advanced ceramics, advanced technical ceramics) — Test method for antibacterial activity of semiconducting photocatalytic materials | Rhodamine

Biocidal effect Antibacterial activity |

| ISO 27448:2009 | Fine ceramics (advanced ceramics, advanced technical ceramics) — Test method for self-cleaning performance of semiconducting photocatalytic materials — Measurement of water contact angle | Self-cleaning properties

Effect Water contact angle change |

| ISO 10678: 2010 | Fine ceramics (advanced ceramics, advanced technical ceramics) — Determination of photocatalytic activity of surfaces in an aqueous medium by degradation of methylene blue | Degradation of the dye molecule methylene blue (MB) in aqueous solution using artificial ultraviolet (UV) radiation |

| BS EN 1096-5:2016 | Glass in building. Coated glass. Test method and classification for the self-cleaning performances of coated glass surfaces | Self-cleaning performance |

| BS EN 1096-2:2012 | Glass in building. Coated glass. Requirements and test methods for class A, B and S coatings | Glass façade coatings |

| ASTM E2546 – 15 | Standard Practice for Instrumented Indentation Testing | To quantitatively measure various mechanical properties of thin coatings |

| ASTM E2180 – 07(2012) | Standard Test Method for Determining the Activity of Incorporated Antimicrobial Agent(s) In Polymeric or Hydrophobic Materials | Evaluate effectiveness of antimicrobials in hydrophobic materials |

| ASTM F21 – 14 | Standard Test Method for Hydrophobic Surface Films by the Atomizer Test | |

| ASTM C813 – 90(2014) | Standard Test Method for Hydrophobic Contamination on Glass by Contact Angle Measurement | |

| JIS R 1701-1 2010 | Fine ceramics (advanced ceramics, advanced technical ceramics) – Test method for air purification performance of photocatalytic materials – Part 1: Removal of nitric oxide | Air purification effect

Nitric oxide removal

|

| JIS R 1701-2 2008 | Fine ceramics (advanced ceramics, advanced technical ceramics) — Test method for air purification performance of photocatalytic materials — Part 2: Removal of acetaldehyde | Acetaldehyde removal |

| JIS R 1701-3 2008 | Fine ceramics (advanced ceramics, advanced technical ceramics) — Test method for air purification performance of photocatalytic materials — Part 3: Removal of toluene | Toluene removal |

| JIS R 1702: 2012 | Fine Ceramics (advanced Ceramics, Advanced Technical Ceramics) – Test Method For Antibacterial Activity Of Photocatalytic Products And Efficacy | Methylene blue decomposition

Biocidal effect Antibacterial activity |

| JIS R 1703-1: 2007 | Fine ceramics (advanced ceramics, advanced technical ceramics) — Test method for self-cleaning performance of photocatalytic materials — Part 1: Measurement of water contact angle | Self-cleaning

effect Water contact angle change

|

| JIS R 1703-2: 2014 | Fine ceramics (advanced ceramics, advanced technical ceramics) — Test method for self-cleaning performance of photocatalytic materials — Part 2: Decomposition of wet methylene blue | Specifies the measurement of the decomposition performance in an aqueous medium among indices which affect the self-cleaning performance of flat-plate shaped photocatalytic materials |

| JIS R 1704: 2007 | Fine ceramics (advanced ceramics, advanced technical ceramics) — Test method for water-purification performance of photocatalytic materials by measurement of forming ability of active oxygen | Water purification effect Active oxygen-forming |

| JIS R 1705: 2008 | Fine ceramics (advanced ceramics, advanced technical ceramics) — Test method for antifungal activity of photocatalytic products under photoirradiation (Amendment 1) | Antifungal activity |

| JIS R 1709: 2007 | Fine ceramics (advanced ceramics, advanced technical ceramics) — Light source for test of photocatalytic materials used under ultraviolet | Light source for test under

UV irradiation |

| JIS Z 2801 | Test for Antimicrobial Activity of Plastics | Tests the ability of plastics, metals, ceramics and other antimicrobial surfaces to inhibit the growth of microorganisms or kill them |

| UNI 11247: 2007 | Determination Of The Degradation Of Nitrogen Oxides In The Air By Inorganic Photocatalytic Materials: Continuous Flow Test Method | Photocatalytic self-cleaning material |

| UNI 11238-1: 2007 | Determination Of The Catalytic Degradation Of Organic Micropollutants In Air – Part 1: Photocatalytic Cementitious Materials | Removal Volatile Organic Compound |

| UNI 11238-2: 2007 | Determination Of The Catalytic Degradation Of Organic Micropollutants In Air – Part 2: Photocatalytic Ceramic Materials For Use In Construction | Removal Volatile Organic Compound |

| UNI 11259: 2008 | Determination Of The Photocatalytic Activity Of Hydraulic Binders – Rodammina Test Method | Rhodamine |