Mixing of Concrete

Concrete shall be mixed in a batch type mechanical mixer. The quantity of constituent material in each batch shall not exceed the rated capacity of the mixer. The constituent material shall be thoroughly and continually mixed at the mixing speed specified by the mixer manufacturer until the resulting concrete is uniform in colour and consistency.

The mixing time shall be as follows:

- Pan mixer – minimum 30 seconds

- Truck mixer or drum mixer – minimum 1.5 minutes for 1 m3 of concrete plus 0.25 minute for each additional 1 m3.

The mixing time shall be reckoned from the time when all the solid materials are in mixer. No portion of the time required for discharging shall be considered as part of the mixing time.

The first batch of concrete fed into the mixer shall have an increase of an appropriate amount of dry mortar similar in proportion to that of the concrete to be mixed and of mixing water for coating the mixer.

The mixer shall be emptied completely before being refilled. Mixers which have been out of use for more than 30 minutes shall be thoroughly cleaned before any fresh concrete is mixed. The mixer shall be free from hardened concrete. Worn-off blades or paddles shall be replaced.

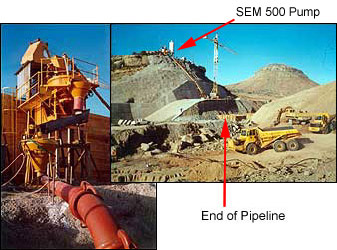

Following are the few modern concrete mixing equipments.

Further Reading:

[1] Concrete Mixing Method and Concrete Mixtures 1

[2] Concrete Mixing Method and Concrete Mixtures 2