Case 2

- Introduction

- Causes of Defects

- Good Practices

- Standards

- Maintenance and Diagnostics

- Remedial

- Similar Cases

- References

Maintenance and Diagnostics

Maintenance

In general, good quality concrete does not require extensive maintenance. However, due to external factors it might have some defects even before reaching its design life.

Regular inspections and checking should be hence carried out periodically at regular intervals to detect these defects and to take remedial action to remove these defects. An efficient inspection system should be adopted to ensure the conduct of regular checks such as visual inspections periodically.

Suitable instruments and techniques should be used to diagnose defects properly. Diagnosis involves a process in which experts investigate the buildings’ conditions, carry out tests, evaluate, make recommendations for remedial actions where necessary and predict the future performance of a building.

Even the best masonry requires periodic maintenance to ensure its continued successful performance.

Although the brick units are quite durable over time, other materials in the wall system will require periodic repair and/or replacement.

Typical maintenance items which should be addressed are repairing of cracks in masonry, cleaning clogged weepholes, removing stains and efflorescence, repainting steel, replacing caps or copings, repointing mortar joints (tuck-pointing), replacing deteriorated sealants and caulking, and cleaning the masonry.

Cleaning New Masonry

- Bucket and Brush Hand Cleaning

- Pressurized Water Cleaning

- Sandblasting

Cleaning Existing Masonry

There are four cleaning techniques for existing masonry.

Diagnostics of Defect (see also NDT)

Finding the source of water ingress into the facade system is most crucial. The following methods are recommended:

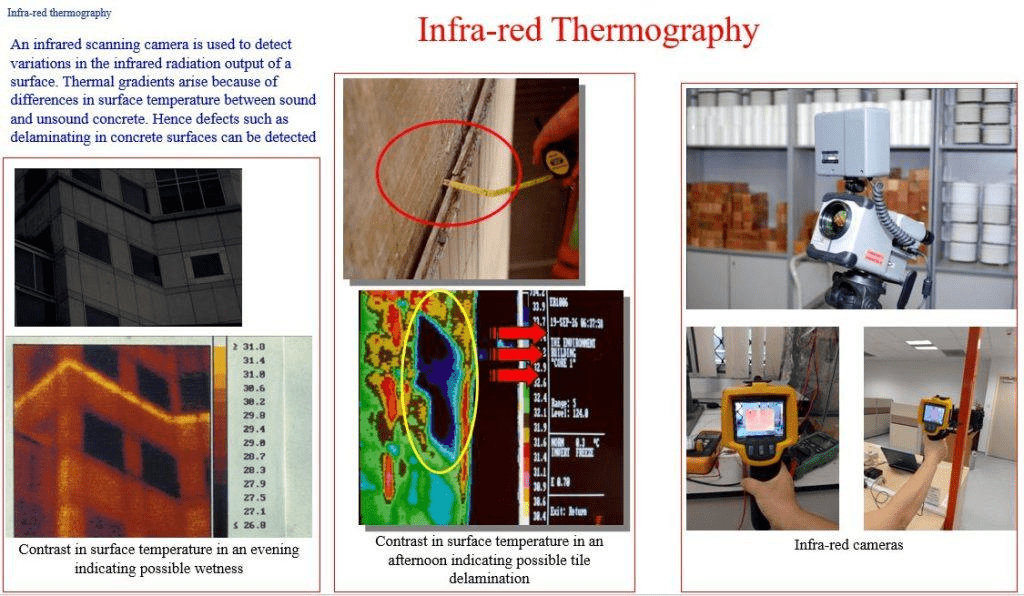

Thermography can be used to identify the position of cracks. A range of crack widths, representing mechanical damage, has been induced under controlled laboratory conditions. The method is based on the characteristics of heat flow phenomenon, in a conductive medium of specific geometry, which is intended to model predetermined boundary conditions.

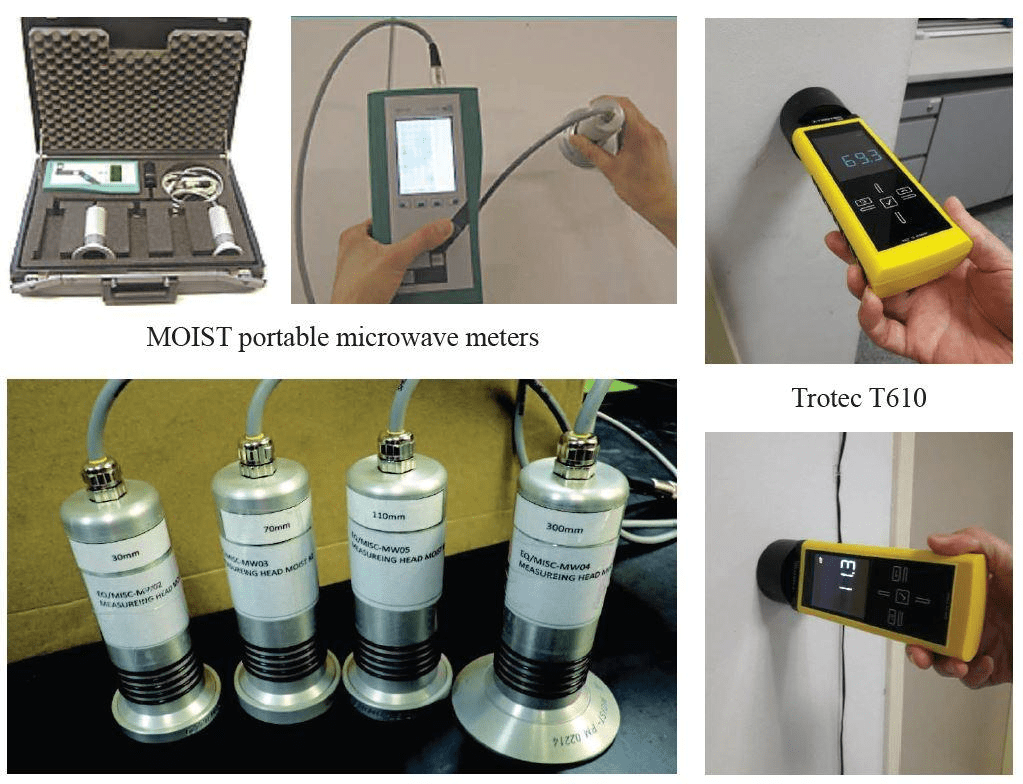

Microwave tomography is a technique to measure the moisture of various materials based on the relatively high dielectric constant of “water” in comparison to the dielectric properties of the material. An electrical field (microwave) is applied to the material, and the microwave induces oscillations of bipolar molecules (i.e., water). Water molecules will reflect and absorb an electrical field during oscillations. A higher electrical field reflected indicates higher water content.

The technique is non-destructive and applicable to wood, brickwork and concrete. The uniqueness of this technique is its ability to measure moisture content at various depths up to 110 mm, allowing the plotting of a 3-D contour of moisture content and facilitating the tracing of the water source.