BIPV/PV

Good Practices

Cleanability

Maintenance for BIPV buildings has been an area of research in recent times, especially in terms of cleanliness, which would in turn affect the efficiency of the panels. Research conducted in California during a 145-day drought have findings that leaving the PV panels unclean over a period of time did not result in much efficiency loss as promoted. In fact, it only led to a loss of 7.4% in efficiency, which translated to a loss of $20 of electricity production in their research sample15. While larger applications of BIPV would lead to larger losses, the cost of hiring specialised companies to clean the panels on a monthly basis may outweigh the efficiency loss. It should be noted that the research was done primarily to handle the issue of dust and small organic particulates accumulating on the panels. Also, bird droppings must still be cleaned off because they do block sunlight and is not able to be washed away by rain16.

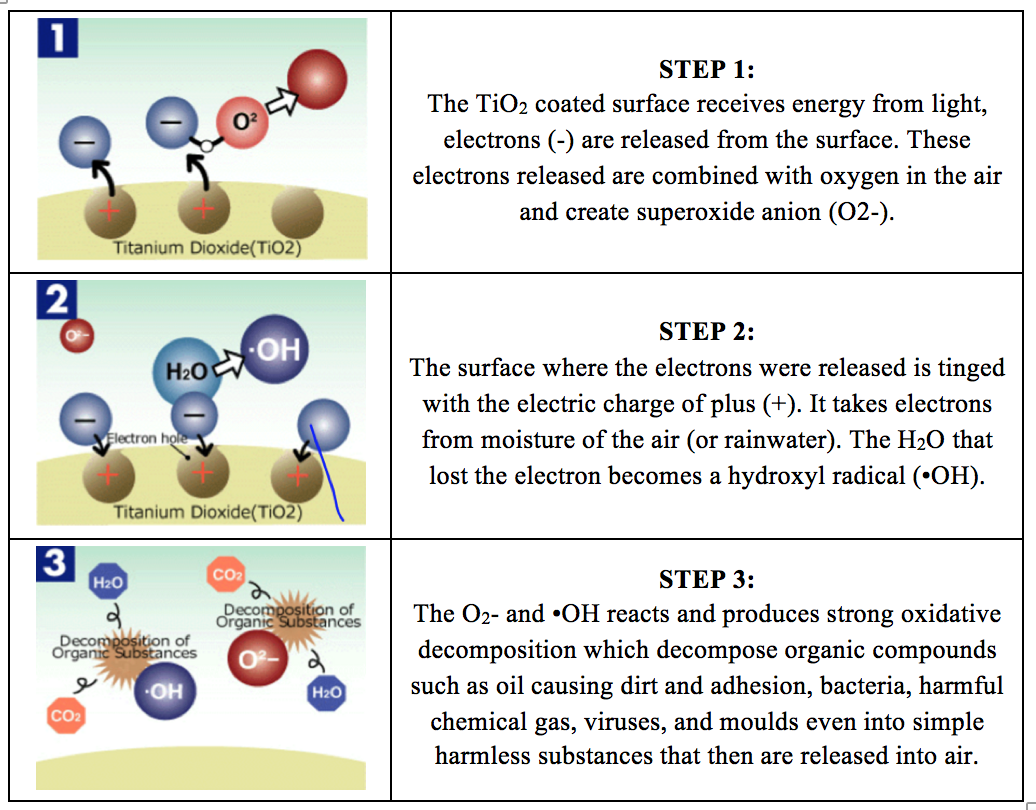

With much improvements in design, BIPV and PV modules have the capability of self-cleaning for easy maintenance17. Thus, in the current generation of BIPV/PV modules will be coated with Photocatalytic Coating. The photocatalytic coating can serve as a protective layer for the PV modules on the façade. This enables the cleaning of façade to be much easier, especially for high-rise buildings. Light radiation and water are the basic components for self-cleaning to work. The coating, titanium dioxide (TiO2), is applied to the façade by brush, spray ground, or roller depending on the circumstances. Not only the coating allows for chemical reaction to remove dirt, its hydrophilic nature enables the rain water to run through without leaving a stain.

The plus charge at the surface of the coating takes up the electron from H2O and return to its original state. This explains why the TiO2 coating has a permanent effect.

The rainwater gives out the electron and combines with the superoxide anion to decompose the unwanted organic compounds. This, however, may leave water stains on the façade surface. Hydrophilic nature of the photocatalytic coating shapes the raindrops to form less than 20° angle with the façade surface, causing the raindrops running down without leaving a water stain.

This resulted in the ‘self-cleaning’ effect like shown in the Figure 6 above. Even so, regular visual inspection is still necessary for which there is a case of the lacking of rainwater to wash the dirt away. Reapplication of the coating is also required due to the effect of wear and tear.

Accessibility

Using the case study in Singapore, design considerations such as accessibility have been taken into account for ease of maintenance. As shown in Figure 7, concerning glass façade cleaning where space provisions have been made for the necessary equipment such as gondolas. There are plenty of spaces to walk around the perimeter of the facade. The cleaning is assisted with equipment such as gondola and wiring placed at one corner of the working platform. This equipment is placed away from the entrance to the working platform as shown in the figure to ensure the safety of the visitors and users.

Moreover, safety harnesses are placed together with other equipment. This would translate to better safety considerations accounted when carrying out regular cleaning and maintenance. In addition, there is a rail mounted to support the gondola used by the workers to clean the window as shown in Figure 8.

Replaceability

When considering for replacement of BIPV, it will differ according to how the PV is mounted. If the BIPV is mounted with a clamp, then it is easy to be replaced as compared to those mounted vertically due to the higher cost of replacing the cells. One concern would be that when one PV modules are not working, the whole panels have to be changed so as not to reduce the efficiency. An example of one BIPV panel is shown in Figure 9.

Efficiency

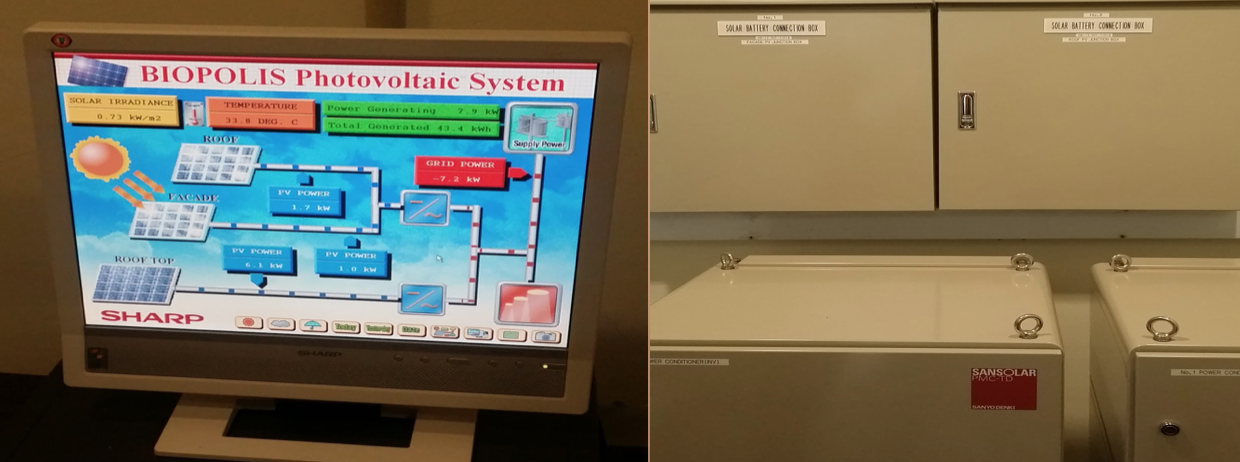

Different parameters should be taken into consideration for the proper function of the BIPV cells. A primary factor affecting the BIPV effectiveness is the temperature of the PV cells18 , which depends on the thermal characteristics of the material composing the PV cells, their type, their mode of encapsulation and installation19, in addition to the weather conditions. The operating temperature of the PV cells should be controlled to avoid the deterioration of performance resulting from exceed of temperature20. In order to check modules efficiency, the building owner can install their own monitoring system to detect the performance of the PV cells. System as depicted below is able to detect the temperature of the PV panels at the different area in the building, the temperature of the facade and the flow of power generated by the PVs.

Furthermore, such a system would be able to keep track on the amount of energy generated by the PV cells. For ease of access to the components of the BIPV like the solar battery connection box and the monitoring system and ease in replacing this components, this system are strategically placed and hence, monitored regularly with ease (see Figure 10).

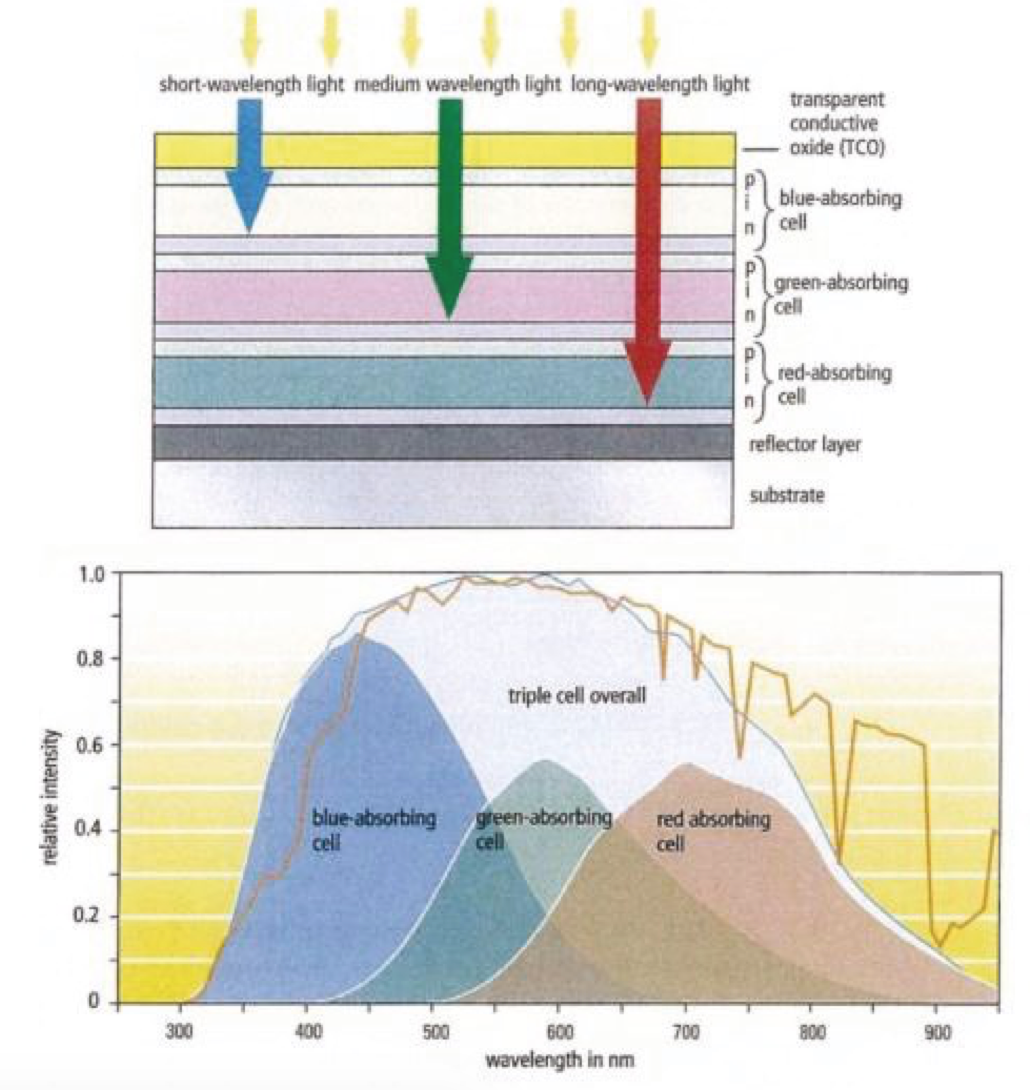

There are various ways to ensure efficiency of BIPV. One proposed method would be to avoid excessive heating temperatures from unabsorbed irradiations – which is to implement a ventilation method through forced or natural convection along the PV panels21. Another strategy utilized to achieve high solar cell efficiencies is to make so-called sandwich or stack solar cells, which use several different material layers and cells with different spectral absorbances to harvest as much as possible of the solar radiation in a wide wavelength range22. An example of a triple solar cell with its configuration and spectral responses is shown in Figure 11. The top cell layer absorbs the blue light and allows the other wavelength parts of the solar radiation to pass through. The green and yellow light is then absorbed by the middle cell layer, and the red light is absorbed by the bottom cell layer. Hence, a much larger portion of the solar radiation is utilized.

Performance Integrity Aspects

Air and water tightness: Air and water tightness is important to ensure the no rainwater or extra vapour leaks into the building; especially when there is IT equipment nearby. Air tightness is also necessary to ensure that the air-conditioning from within the building does not leak out or the extreme heat from outdoors leaking into the building, causing higher amounts of air conditioning needed, leading to higher energy used and eventually more costs incurred. As mentioned in BIPV, PV is integrated into the building elements in the building, which gives an extra energy feature in that particular building element. As such, the installation of BIPV as building facade will work similarly to the common glass facade that is installed as building facade. The extra precaution is to handle the BIPV panels carefully as the PV cells are extremely fragile. As long as the necessary precautions and regulations are taken into consideration to mount and brace the panels, the air and water tightness of BIPV facade will be ensured.

Fire safety: The BIPV panels can be mounted onto a window frame and Other than that, as seen in Helios building, not all panels are BIPV panels. Some panels are actually normal glass panels and they can be allocated as the fire escape safety route for the relevant authorities to get access to the building in terms of fire and emergencies. The BIPV glass panels, having the characteristic of glass, are also fire resistant so as to help the occupants buy time for them to escape to safety before the fire spreads into the building.

Lightning protection system: As facades are exposed to the outdoor environment, protection for the glass panels is essential. Often, BiPV purchase would come with a lightning protection system that complies with SS55123 and SS55524 with appropriately rated surge arresters that are located on the direct current (DC) side of the PV system. The building structural system has to be grounded properly. This is to ensure that when lightning strikes and a huge surge of electricity hits the facade, both the BIPV cells and building structure will not get damaged25.

In conclusion, there is room for improvement in each specific system, e.g. regarding ventilation rate, positioning, removing of dirt, etc. To ensure a good integration, the BIPV systems should be included early in the planning process. Therefore, a well-established communication between the planners and manufacturers of BIPV products is important for the development of new BIPV solutions. For mono- or polycrystalline PV cells it is very important to achieve sufficient ventilation rate, as the solar cell efficiency normally decreases with increasing temperature, and should thus be planned ahead of the construction phase. The BIPV systems are expected to improve in the near future both regarding the efficiency of the product and the production phase, hence leading to decreased energy payback time8.