Ultrasonic Pulse Velocity Measurement Test

Principles

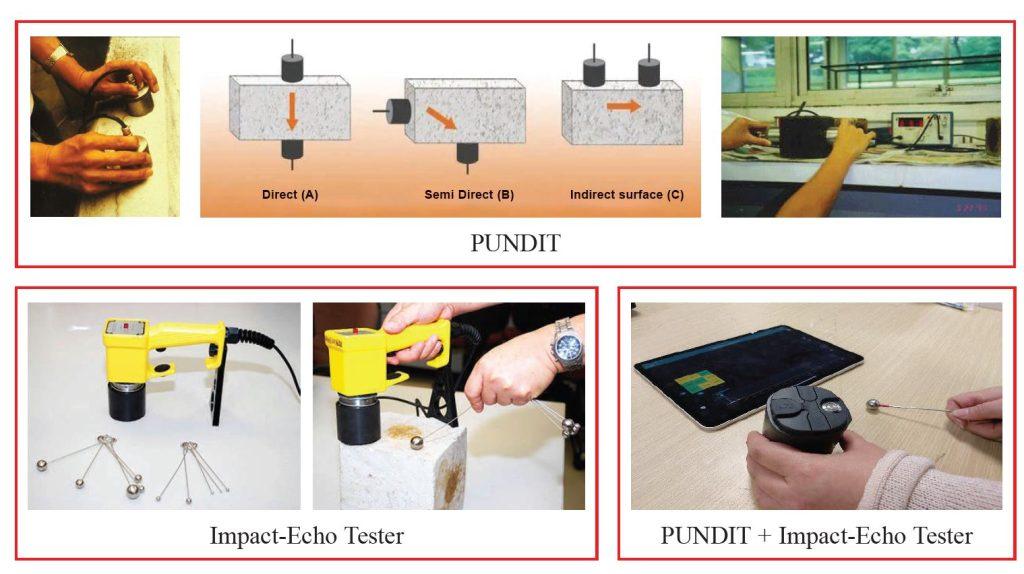

This test is used to estimate the strength of concrete based on the measurement of the time of travel of an ultrasonic pulse passing through the specimen. The tester consists of a pulse generator and a pulse receiver. The time taken for the pulse to pass through the concrete is measured by electronic measuring circuits. Figure 9.24 (top) shows a classical ultrasonic pulse velocity tester named “PUNDIT”, which stands for “Portable Ultrasonic Non-destructive Digital Indicating Tester”.

Usually, if large differences in pulse velocity are found within a structure for no apparent reason, there is strong reason to presume that defective or deteriorated concrete is present. High pulse velocity readings are generally indicative of good quality concrete. Fairly good correlation can be obtained between cube compressive strength and pulse velocity. These relations enable the strength of structural concrete to be predicted within ± 20%, provided the types of aggregate used and mix proportions are constant. Generally, the degree of damage is related to a reduction in pulse velocity. Cracks can also be detected.

Good acoustic coupling between the transducer face and the concrete surface is necessary to ensure accurate transit time measurement. This is done by ensuring that the concrete surface is free from dust and grit and covering the surface with a layer of light/medium grease.

Direct transmission arrangement is usually employed for more accurate measurement, where the two transducers are placed directly opposite each other on the two sides of a concrete wall. However, the examination of concrete using diagonal paths and semi-direct arrangements, though not very accurate, is suitable for other purposes. During measurement, it is preferable to avoid a path arrangement that contains steel reinforcing bars since pulse velocity measurements made in the vicinity of reinforcing steel may be high.

There is no unique relationship between the pulse velocity and the concrete’s strength, as it is influenced by the concrete’s constituents and curing conditions. Nevertheless, if the mix proportions remain constant and only one type of coarse aggregate is used, then it is possible to determine a specific relationship between pulse velocity and strength for in-situ concrete. Besides, moisture conditions also played a significant role in this testing. Owing to these many factors, evaluation of the quality of concrete in structures is usually made on a comparative basis.