Excessive loads leading to breakage of suspension ropes

- Causes

Excessive load due to overloading of passengers

- Description of defect

Ropes may fracture because of excessive load, and in some severe case it can even break the suspension ropes.

Elevator suspension ropes severely damaged [20]

- Diagnostic/testing method

The ropes shall be replaced if they are permanently kinked, bent, or deformed. Below are the criteria that requires ropes replacement (ASME A17.6-2010):

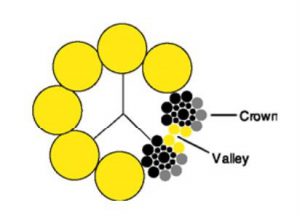

- The broken crown wires are equally distributed among the strands;

- If the broken crown wires are not evenly distributed, but the worst section of ropes exceeds values in ‘normal wear condition’;

- If four wires, side by side, are broken across the crown of any strands;

- Excessive wear and presence of rouge in valley breaks

Valley breaks is a condition where ropes need to be replaced, where the broken wires are visible and occur outside of the crown wear area with the crown wire intact [30]

Condition of broken ropes with presence of rouge indicates ropes need to be replaced [30]

- Good practices

Capacity rate shall be located at a noticeable position in the lift car that indicate rated load in kilograms and maximum number of passengers. Also, the overload weighing device shall be provided and initiate an alarm when there is a case of overloading (SS550)

- Corrections

If one rope of a strand is worn or damaged and require to be replaced, the entire strands shall be replaced, except when the damaged occur during installation where the ropes passed the testing prior to being subjected to elevator service, it shall be permissible to replace one damaged rope with a new rope (ASME A17.6-2010).