Elastic Recovery Test (INERT)

Principle

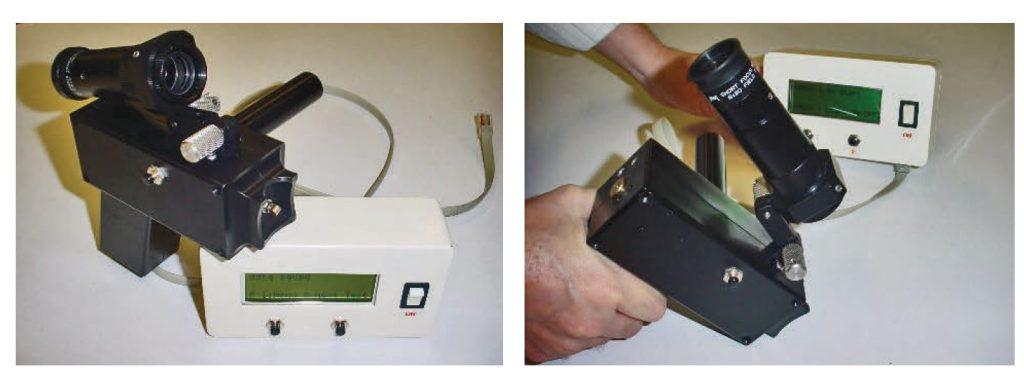

The mechanics of the INERT is based on the Laboratory-based Non-destructive Elastic Recovery Tester (LNERT). The LNERT was a modification from one of the recommended standards. Instead of using the standard penetration tool as in ASTM designation D5, LNERT is set up by replacing the needle with a pellet detector to allow for non-destructive testing.

A digital logger that ensures consistent results replaced the dial gauge employed in the elastic recovery experiments during the development stage. Moreover, the digital logger eliminates manual readings and eliminates parallel, zero and human errors.

The piston load controller is incorporated into the design to ensure that there is uniform load application and consistency. A pellet detector of 5mm in diameter and weighing 0.48g is attached to the end of the controller. The pellet detector is chosen according to the existing joint width size of about 10mm. The weight of the ball bearing is kept minimal to prevent unnecessary loading during elastic recovery. A schematic block diagram of LNERT is shown below.