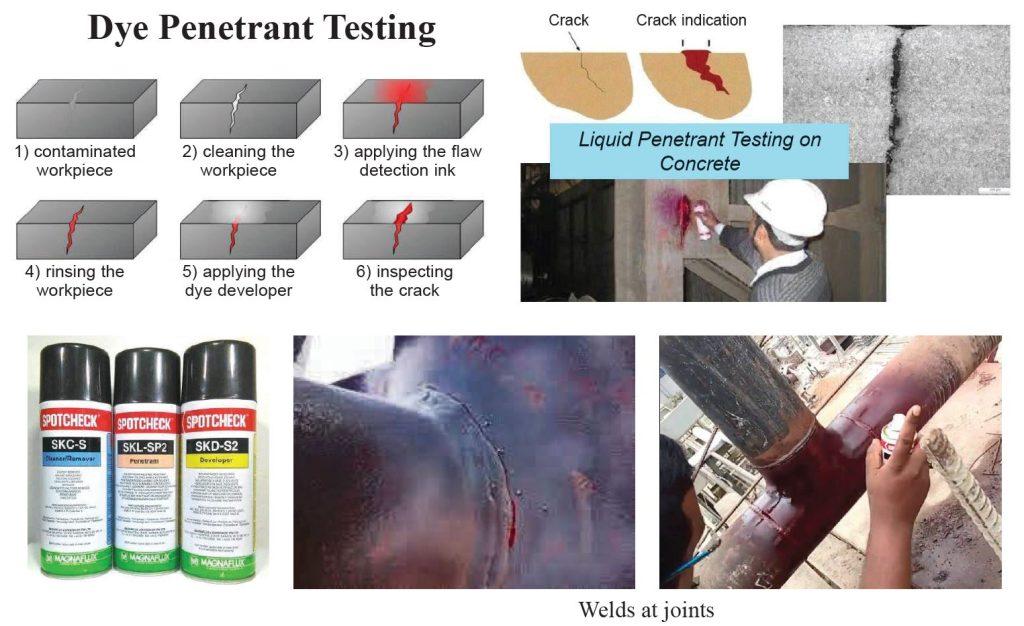

Liquid Penetrant Testing

This method uses a coloured liquid or a dye to detect surface-breaking flaws, such as cracks, laps and folds, on any nonabsorbent material’s surface. It is based on the ability of the liquid or dye to be drawn into a “clean” surface-breaking flaw by capillary action. After a period of time, the excess surface penetrant is removed, and a developer (dry white powder) is applied. The powder draws the penetrant from the flaw by reverse capillary action to reveal its presence (Fig. 9.23). As the coloured indications are broader than the actual anomaly, it makes the anomaly more visible.

Liquid dye penetrant testing is commonly used to inspect the surfaces of non-porous assets made out of ceramics, plastics, and metals, where inspectors will be looking at:

– Welds

– Castings

– Forgings

– Plates

– Bars

– Pipes

In these materials, inspectors will be using dye penetrants to look for defects like:

– Leaks

– Joint flaws

– Fractures

– Porosity on the surface of the materials

– Cracks (cracks from fatigue, hairline cracks, or grinding and quenching cracks)

– Incomplete fusion