Case 1

- Introduction

- Causes of Defects

- Good Practices

- Standards

- Maintenance and Diagnostics

- Remedial

- Similar Cases

- References

Maintenance and Diagnostics

Maintenance

For decisions on surface repairs, consider the ease of access for future work, relative cost of hiring and

erecting scaffolding, and the probable frequency of maintenance in accordance with BS 8221-2, SS 509-2

or equivalent. Record and retain documentation of all executed works on façades, including photographs and non-destructive survey techniques, to provide background information prior to further assessment

or work. Carry out semi-annual inspections of stone-wall elements and inspect all elevations. Keep accurate and cumulative records of inspection findings in accordance with ASTM C1496, BS 8298-1 or

equivalent.

Regular cleaning is critical for the long-term durability and appearance of natural stone façades. Perform

periodic joint repairs (i.e., sealant replacement, tuck pointing, and cleaning) in accordance with ASTM

C1496, BS 8298-1 or equivalent. Perform repairs and restoration works in accordance with ASTM

C1722-18, BS 8221-2 or equivalent. For cases of cracked or broken stones, carry out the following: a) Seek assistance for stone replacement; b) Tuck point or caulk crack with sealant if fragments are stable and secure; c) Monitor closely for additional cracking or movement.

Regular inspections and checking (see also Periodic Facade Inspection) should be hence carried out periodically at regular intervals to detect these defects and to take remedial action to remove these defects. An efficient inspection system should be adopted to ensure the conduct of regular checks such as visual inspections periodically.

Suitable instruments and techniques should be used to diagnose defects properly. Diagnosis involves a process in which experts investigate the buildings’ conditions, carry out tests, evaluate, make recommendations for remedial actions where necessary and predict the future performance of a building.

The important factors to be noted for cracks are:

- width, direction and location

- whether live, dead or growing

- isolated or random

- widespread or confined to particular areas

- associated with other defects or rain entry

- surface erosion effects

Diagnostics of Defects (see also NDT)

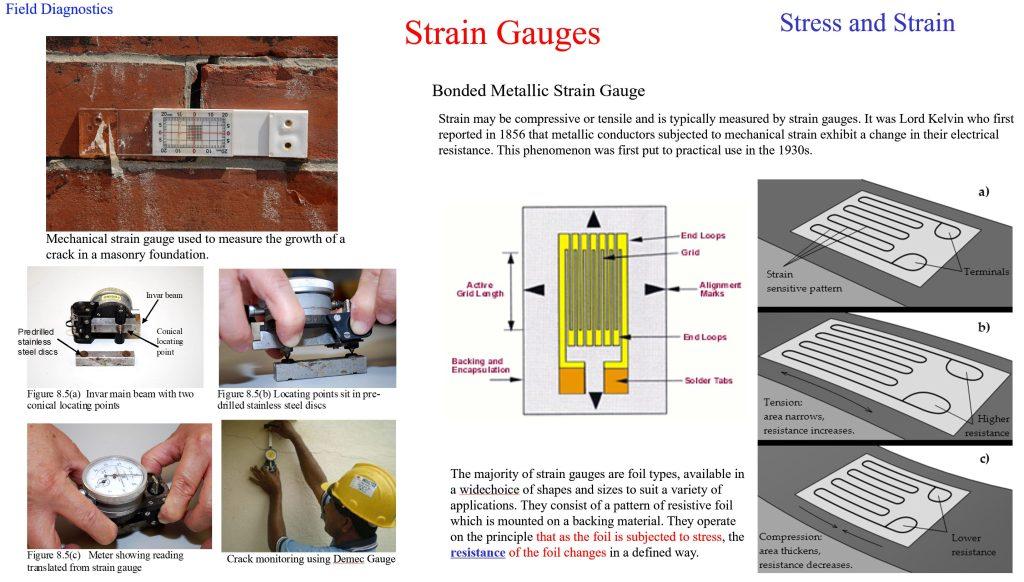

Strain Gauges

The crack type of crack should first be determined via testing (utilizing a mechanical strain gauge)

Hammer Tapping Test

Tapping test may be used to detect hollowness, delamination, spalled or debonded plaster.by listening to the ‘void’ sound.