Case 3

- Introduction

- Causes of Defects

- Good Practices

- Standards

- Maintenance and Diagnostics

- Remedial

- Similar Cases

- References

Good Practices

Design

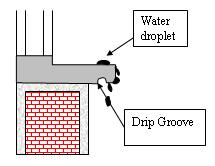

Specify material and application methods for water repellence of porous masonry in accordance with BS 8221-2, SS 509-2 or equivalent. Throw off water from the façade altogether through an outward projecting sill or overhanging eaves (which incorporate a throat or drip lines on its underside) or provide blocking features such as copings/flashings. Use efficient scupper drains/downpipes to channel water down and away from the façade. To provide drip grooves along the underside of projecting features. Specify a paint system, which is permeable to avoid any paint defects which may cause staining.

Render the detailing for open joints as opposed to butt joints to avoid sealant staining. To use nonbleed sealants so as to prevent staining from silicone oil. Recommend joint designs, which are able to retain runoff within joints and expansion joints designated to provide vertical runoff carrying dirt down along the façade surface. Specify façade selfcleaning applications (e.g., TiO2, superhydrophobic paint products, etc.) with due consideration given to site orientation, sunshades and protruding features. To understand the impacts of environmental, material, design and maintenance aspects on rainwater runoff; see “Staining of Facades”.

Construction

Paint façade surfaces evenly with no patchiness. The finished texture should be uniform in colour. Ensure proper rendering to control surface granularity and local faults as it influences colour uniformity of the external façade in accordance with ISO 7361 or equivalent. Correct sealant applications to ensure consistent and continuous quality. Avoid misaligned panels of cladding in accordance with BS 8000-0 or equivalent. Refer to the planning of the painting programme, including inspection regime (initial and routine inspections) for buildings in accordance with BS 6150, SS 542 or equivalent.

Use self-cleaning coatings on newly built substrates for increased success in its performance. All construction/repair works on a façade surface should be done prior to application of a water repellent in accordance with BS 8221-2, SS 509-2 or equivalent. For serviceability of exterior façade surfaces, adopt ASTM E1667-95a or equivalent. It is important as it dictates the building’s individual and corporate identity. The correct application of TiO2 coating is crucial to ensure proper adhesion to the substrate. It is also challenging to check the proper application of the coating, especially on high-rise buildings, due to

its transparent property.

Maintenance

Consider availability of adequate water supply, drainage provisions and electrical power supply to choose a façade cleaning method. Records of cleaning operations (including photographs before and after cleaning, and drawings of nature of deposits, thickness and patterns) should be kept for buildings of significance in accordance with BS 8221-1, SS 509-1 or equivalent. Maintain the façade in a state as near as possible to its new condition. Ease of façade maintenance can be expressed by the frequency of necessary maintenance operations, labour and supplies necessary for each maintenance operation,

and number of possible ways of removing stains, graffiti, etc., or ISO 7361 or equivalent.

Detect/determine staining of porous substrates by joint sealants (ISO/NP 16938-1). Adopt the recommendations for treatments for controlling organic growth in accordance with BS 8221-2, SS509-2 or equivalent. Repair painted surfaces damaged by wear and tear; wash down; remove defective paint film; apply sealer/primer (if necessary); and repaint in accordance with BS 6150, SS 542 or equivalent. TiO2 only works where there is sunlight. Conventional cleanings are still needed for non-coated areas. For areas coated with TiO2, conduct neutral cleaning annually.

Brick

Design

Design and plan well. Attention must be paid to waterproofing the brickwall. Important considerations to place on:

- Design recommendations

- wall types,

- workmanship characteristics,

- detailing, flashing,

- drips and weep holes

Methods of reducing rain loads through building design:

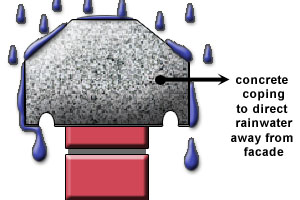

- adequate copings on wall

- more efficient weepholes or other water drainage devices where there is a risk of water entering

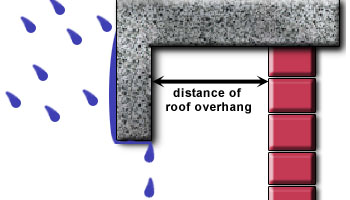

- generous roof overhangs

- devices to keep water off the facade, such as window sill and roof gutters

Material

- Selection of bricks should meet the requirements of relevant standards.

- All bricks should be accompanied by the manufacturer’s certificate.

Construction

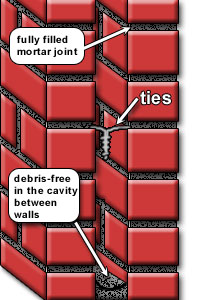

- Workmanship characterized by the complete filling of all mortar joints intended to receive mortar is desirable, as is the need to keep all cavities clean and free of mortar droppings.

- Attention to both of these items is of primary importance in preventing moisture penetration to the interior of masonry.

- Protection

- Partially completed masonry walls exposed to rain and other elements during construction may become saturated with water and can require weeks, or even months (depending on climatic conditions), after the completion of the building for the masonry to dry. This prolonged saturation may cause many “slightly” soluble salts, as well as the highly soluble salts, to go into solution. Such conditions may also contribute to the contamination of the masonry with soluble salts from elsewhere in the construction (concrete, plaster, trim, etc.).

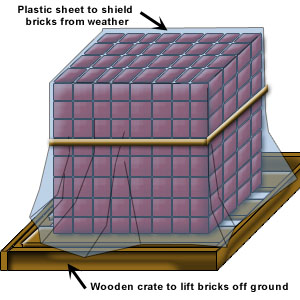

- During construction, all walls should be kept dry by covering with a strong, waterproof membrane at the end of each workday or shutdown period. These are used in conjunction with plastic sheets or water-repellent tarpaulin material and offer excellent protection for extended periods of time.

Quality control

Conduct water test to the external full height facing brick walls to test the watertightness of external wall construction.

Storage

Masonry units should be stored off the ground to avoid contamination by dirt and ground water which may contain soluble salts.

Mortar

Design

| Basic composition | Cement: lime: sand with air-entrainment | Cement:sand with air entrainment | Cement:Lime:sand | ||

| Binders | Ordinary Portland cement or sulphate-resisting Portland cement | Masonry cement with high lime content (1:1:OPC:lime) | Masonry cement with other than high lime content | Ordinary Portland cement or sulphate-resisting Portland cement | |

| Designation | |||||

| (i)(ii)(iii)(iv) | 1: 1/2: 4/1/2 +Air1: 1: 5/1/2 +Air | 1: 31: 4/1/2 | 1: 2/1/2-3/1/21: 4-5!: 5/1/2-6/1/2 | 1: 3-4 + Air1: 5-6 + Air1: 7-8 + Air | 1: 0-1/4:31:1/2: 4-4/1/21:1: 5-61: 2: 8-9 |

Table 1: Mortar mixes and designations

Material

- Use prepacked mortar for consistency

- It should be noted that the principal contribution to lime leaching in mortars is the high alkali content of the portland cement. Cements high in alkaline content are more prone to produce efflorescence than cements of lower alkali content.

- Other ingredients for mortar, i.e., lime, sand and water, should also be selected with care, although their contribution to efflorescence may be less frequent.

- Mortar types and proportions should be selected on the bases of structural and exposure requirements for the particular project.

Construction

- Mechanical mixing of prepacked mortar is advisable. Mixing time should be approximately 10 minutes to achieve good workability.

- Fill all mortar joints solidly

- Clean all excess mortar from mortar joints.

Storage

Cementitious Materials

Cementitious materials for mortar should be stored off the ground and either inside or under cover.

Sand

Sand for mortar should also be stored off the ground to prevent contamination from dirt, plant life, organic materials and ground water, any of which may be a contributor to efflorescence. In addition, it is advisable to store sand and other aggregates under a protective membrane cover, if possible.

Construction

- During construction, ensure that most if not all water used in mortar joints has dried out before application of damp-proof course (DPC) or damp-proof membrane (DPM).

- Lay the damp proof course weighing 3.3 kg m2 to break joint on a layer of cement and sand mortar laid immediately at a level 150mm to 220mm above the ground level in brickwalls.

- Bed all DPCs on fresh mortar

Water repellent and surface coating system

Clear water repellents are most effective at reducing the amount of water absorbed by the brick masonry.

Surface preparation is important. The surface on which the coating is to be applied has to be:

- cleaned by grinding, chemical etching or blasting.

- dried by allowing the wall to cure for a few days before the coating is applied. During rainy periods, the walls should be protected with a plastic covering so that the drying is not interrupted.

Other surface protection systems include:

- Impregnation systems:

- Prevent penetration of water and solutions into concrete without hindering the escape of internal moisture from concrete

- Materials used:

- silicon organic solutions

- resins

- oils

- Sealers

- Heavy barrier against penetrating solutions but may hinder the escape of internal moisture

- Materials used:

- epoxy resins (EP)

- polyurethane resins (PU)

- unsaturated polyester resins (UP)

- Coatings

- compared to sealers, they provide additional protection against mechanical influence.

- increased resistance to diffusion of internal moisture

- Materials used:

- plastic modified cement systems and resins

Weathering paints may be used to coat bricks to improve aesthetics.

Controlling ground water movement

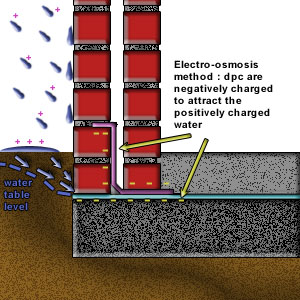

Usage of non-traditional treatment of electro-osmosis DPC that controls the movement of groundwater into the wall by the installation of continuous electrode system in wall at the DPC level.

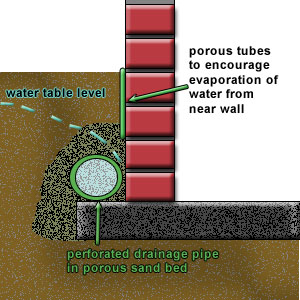

Lowering the groundwater level near the wall by providing site drainage or subsoil drainage; this would reduce the amount of ground water reaching the wall. Insertion of porous tubes into the outer surface of the wall; this would increase evaporation from the wall.