Case 5

- Introduction

- Causes of Defects

- Good Practices

- Standards

- Maintenance and Diagnostics

- Remedial

- Similar Cases

- References

Remedial

To minimize this problem, do not use any acidic solutions on tan, brown, black or gray brick. There are special proprietary cleaning compounds available for cleaning brick containing manganese. These may be tested for effectiveness. The advice of the brick manufacturer should be requested and followed.

The permanent removal of manganese stain may be difficult. After initial removal it often returns. The following method has been effective in removing “brown stain” and preventing its return [1].

- Carefully mix a solution of acetic acid (80% or stronger), hydrogen peroxide (30-35%) and water in the following proportions by volume: 1 part acetic acid, 1 part hydrogen peroxide, and 6 parts water. Caution: Although this solution is very effective, it is a dangerous solution to mix and use. Acetic acid-hydrogen peroxide may also be available in a premixed form known as peracetic acid. This acid, a textile chemical, is also dangerous and may be difficult to purchase.

- After wetting the brickwork, brush or spray on the solution. Do not scrub. The reaction is usually very rapid and the stain quickly disappears. After the reaction is complete, rinse the wall thoroughly with water.

An alternate solution suggested for new and light colored “brown stains” is oxalic acid crystals and water. Mix 1 lb of crystals (0.45 kg) to 1 gal (3.79 L) of water. There are also proprietary compounds formulated to remove “brown stains”. Their effectiveness should be judged only after testing.

Proprietary compounds have been used and sometimes found to be effective in keeping the stain from re-appearing. Consult the recommendations and directions of the cleaning solution or brick manufacturer when applying proprietary solutions to remove manganese stains.

Find the source of water ingress, stop further water ingress using methods such as sealing, injection, impregnation (see Remedial).

Removal of Efflorescence

-If efflorescence exists on an existing surface, the best method of cleaning or removing it, would be to use an acidic cleaner. These salts and minerals would readily dissolved in these acidic cleaning agents.

-Care should be taken when using these acidic agents which may be corrosive in nature.

-Occasionally, the cleaning and removal process can become more difficult if latex or chemical transmission occurs at the same time as the salts and minerals surfaced. These latex or comparable chemicals are often found in the more recent and advanced cementitious adhesives and grouts available and can form a protective layer which defends the efflorescence from direct contact with acidic cleaning products.

-To help solve this problem, select an acidic product that has cleaning agents in it (acid and cleaner in one single product). Another recommendation would be to use a high alkaline restoration cleaner to break down the latex protective coating, rinse well and then proceed with the acidic cleaning.

Repair: Application of Water Repeller

This type of solution act as a hydrophobic surface by penetrating into the pores of the bedding or screed layers and tightening the pores such that the water is not allowed to penetrate through.

It allows vapour to escape and prevent any development of hydraulic pressure caused by the retained moisture.

Repair: Application of Water Proofer (Silicate based)

This kind of solution reacts with the free lime in cementitious materials and seals the pores and cracks in the surface. In fact, as long as moisture and free alkali is present, the reaction will continue by sealing pores. This can also be referred to as “active” repair.

Repair: Application Water-based Clear Coating (with polymer particles)

In this treatment the floor is ponded with the solution and allow the super fine polymer particles to penetrate into the porous structure to form a permanent and continuous plug.

Masking of staining

If removal is too difficult, masking of the haze may be considered. In time, weathering will remove both the masking solution and white scum.

Masking solutions may consist of paraffin oil and Varsol, or linseed oil and Varsol, applied by brush to the affected brick units. Linseed oil and Varsol (10-25% linseed oil) or paraffin oil and Varsol (2 to 50% paraffin oil) will darken light colored brick.

Several batches of solutions with various concentrations should be mixed and tested. Generally, solutions of 2 to 25% paraffin oil will be satisfactory. Allow 4 to 5 days of warm drying weather to pass, preferably at 70 ƒF (21 ƒC) minimum, before a judgment is made on the effectiveness of the solutions.

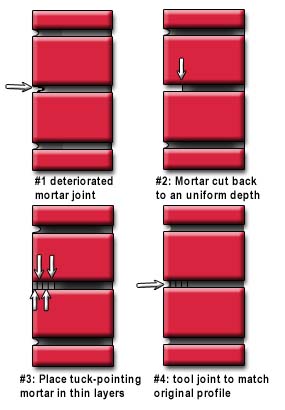

Repointing

After cleaning, the mortar joints should be inspected. Tuck-pointing of the joints may be necessary.

It should be noted that these and all cleaning procedures should first be tried in an inconspicuous area at different concentrations and judged on effectiveness.

Moisture may penetrate mortar which has softened, deteriorated or developed visible cracks. When this is the case, tuck-pointing may be necessary to reduce moisture penetration. Tuck-pointing is a process of cutting out old mortar to a uniform depth and placing new mortar in the joint.