Case 2

- Introduction

- Causes of Defects

- Good Practices

- Standards

- Maintenance and Diagnostics

- Remedial

- Similar Cases

- References

Maintenance and Diagnostics

Proper preventive measures may be able to minimize the occurrence of such staining. One proactive approach to reducing the number of cleaning cycles is by incorporating strategies such as self-cleaning façade. Studies have shown that superhydrophobic surface applications can yield a surface to have such self-cleaning properties. Superhydrophobic self-cleaning technologies are increasingly used in commercial products due to its aesthetic, economic and environmental benefits, including water repellency, breathability, prevention of façade blisters, UV protection, resistance to biological agents, reduction of cleaning resource usage, corrosion and pollutant resistance. Photocatalytic coatings such as TiO2 are also found to be effective on external façade to cut dirt build-up and reduce maintenance as an anti-staining coating for building facades; due to its self-cleaning, anti-bacterial, anti-viral, fungicidal, anti-soiling properties. TiO2 is also both acid and alkali resistant and is harmless to humans.

In order to make informed decisions to combating this maintenance issue, it will do facility managers good to understand how algae propagate and how strategies such as self-cleaning façade technologies can be used to inhibit it. This knowledge can help the facility managers prepare the buildings against algae infestation instead of merely conducting corrective measures. Therefore, determining and understanding the in-service performance information on façade systems is useful in determining proactive maintenance interventions and realistic operational budget estimates. It is apparent that self-cleaning façade coating systems may require a lesser frequency of maintenance interventions which may, in turn, be favourable on a facility’s operating costs.

Carry out regular cleaning by chemical and mechanical applications (e.g., alkaline or solvent cleaning

agents, hydrofluoric acid, air or water abrasive cleaning) and clear dirt regularly in accordance with SS 509-1, BS 8221-1 or equivalent. Remove moulds, lichens and other growths with a stiff brush and treat the residue with biocide chemicals. Use paint, which does not support mould growth. If affected, remove infected paint and sterilise the surface by applying a fungicide solution/algaecide solution to prevent recurrence in accordance with BS 6150, BS EN ISO 1513, SS 542 or equivalent.

Periodic re-painting (about 5-7 years period) is necessary so as to keep the surface free from such peeling.

Biological growths on a building façade may be controlled for short periods by the application of biocidal washes.

If biological growths are largely a consequence of moisture retention caused by the shading of a building façade by overhanging vegetation, these vegetation may be cut back or removed.

Regular cleaning should be performed to cleanse the granite stone of any spores of algae or fungi.

Do not use acid-based cleaners (below pH 7), high alkaline (above pH 9) cleaners or strong degreasers for maintenance.

It is also recommended to reapply sealers to stones every 2-5 years to ensure continued performance of granite cladding.

Diagnostics of Defects (see also NDT)

Visual Inspection

Conduct a comprehensive visual inspection.

Age is not necessarily a main contributing factor to algae attack. More importantly determinants are the amount of exposure, susceptibility to attacks and surface treatments. A building that is orientated towards the North is most prone to biological attacks. Surfaces facing the morning sun are less prone to attack since surface temperature of the finish is raised above that suitable for algae growth.

Visual inspection of the building is sufficient to identify the affected areas.

The following tests can be used to assist with the diagnosis:

See also Staining of Facades

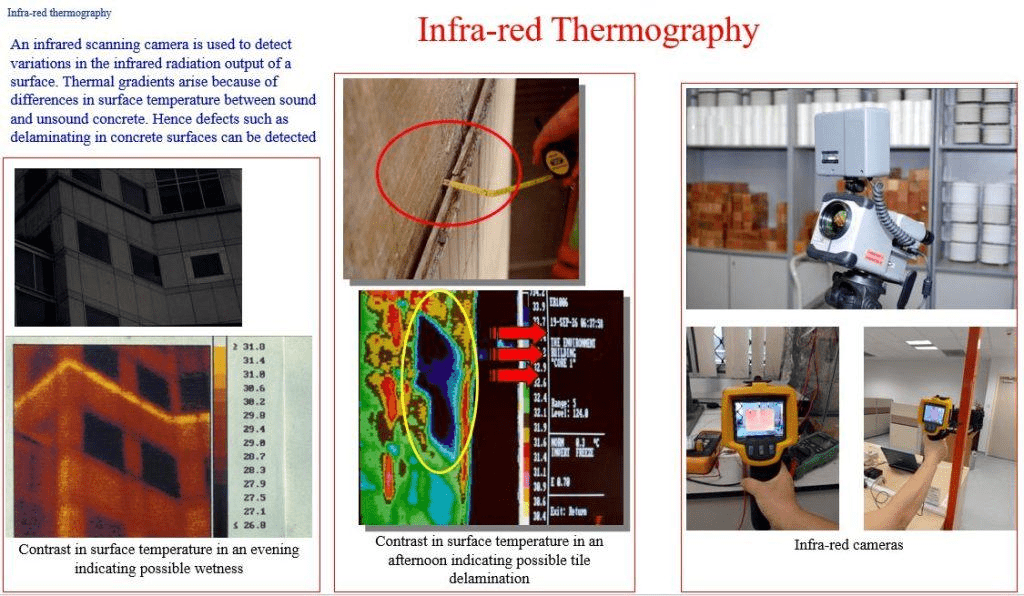

Thermography can be used to identify the position of cracks. A range of crack widths, representing mechanical damage, has been induced under controlled laboratory conditions. The method is based on the characteristics of heat flow phenomenon, in a conductive medium of specific geometry, which is intended to model predetermined boundary conditions.