Case 4

- Introduction

- Causes of Defects

- Good Practices

- Standards

- Maintenance and Diagnostics

- Remedial

- Similar Cases

- References

Remedial (see also Remedial)

A successful repair method depends firstly on having correctly identified the cause of failure. Secondly, there must be a conservative design with some built-in overcapacity to allow for deterioration in sealant properties with age, and for the fact that not every joint may move which increases the amount of movement at other joints.

Total Replacement Method

Once the sealant has been removed, and the joint has been thoroughly cleaned out, the backup material is installed first to the required depth, making sure that it is firmly held and will not be dislodged by the pressure of the sealant being applied on top of it. If a bond breaker is not included as an integral part of the backup, then a separate bond breaker should be carefully applied on top of the backup material.

Primers are usually necessary on most substrate to achieve maximum adhesion. They may prevent penetration of moisture from the substrate to the sealant, which can cause loss of adhesion, or penetration of UV radiation through glass which can have the same effect. They may also protect the substrate from being stained by the sealant. It may be necessary to mask the edges of the joint to prevent the primer from staining the substrate.

Bandage Repair Method

A new capping layer of sealant is simply applied over the existing sealant in the joint, i.e., the failed sealant is not removed. Debonding between new and old sealant is achieved by deliberately selecting a new sealant which will not stick to the old one.

Replace the deteriorated sealants

The sealant joints in these areas should be inspected.

If the sealant is missing, a full bead of high-quality, permanently elastic sealant compound should be placed in the open joints. If a sealant material was installed, but has torn, deteriorated or lost elasticity, it should be carefully cut out.

The opening should be clean of all old sealant material.

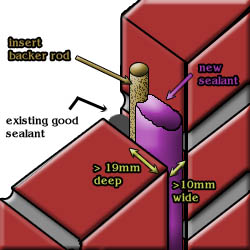

A new sealant should then be placed in the clean joint. All joints should be properly primed before the new sealant material is applied. A backer rope material should be placed in all joints deeper than 3/4 in. (19 mm) or wider than 3/8 in. (10 mm).

The composition of the grout or adhesive should be known when carrying out patch repair or re-grouting of joints to ensure that the repaired works can perform as it was originally designed for. For example, using inappropriate materials for re-grouting might lead to inability of the joint to accommodate movement, which might result in other defects such as cracking to surface.

Identifying the type and colour of the original grout poses a problem (above figure) as the grout changes colour over their useful life. Even if it is possible to correctly identify the grout, there is no guarantee the new grout will match perfectly; it may not even match at all after it is installed and allowed to cure and dry out.

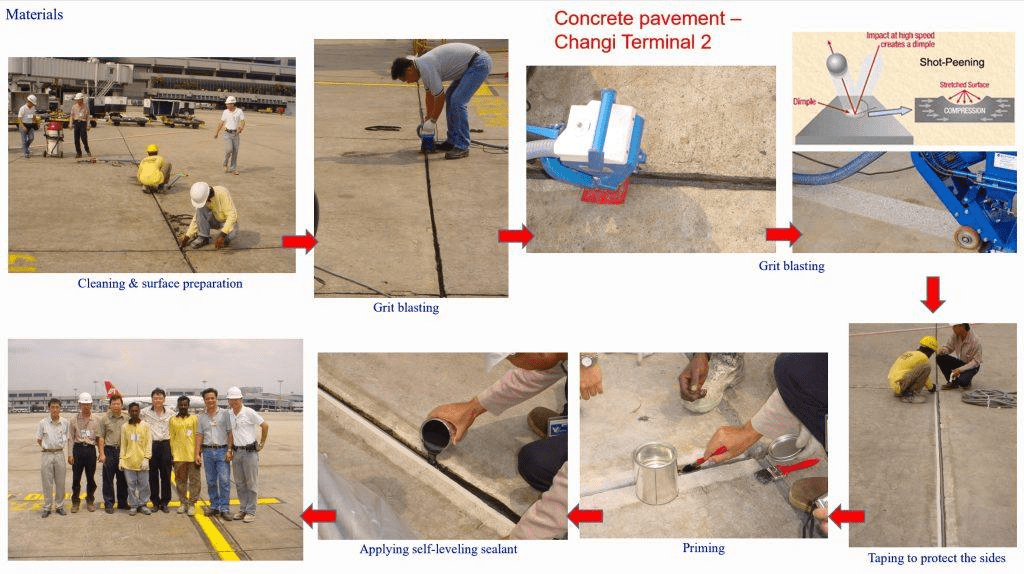

Clean the surface using wire brush, high pressure water jet, grit blasting etc. according to the condition.

Apply tape to protect the adjacent surface: