Prestressed Precast Concrete

Defect and Repair

| Defect | Repair |

| 1. Cracks

Cracks in concrete may originate from one or more of the following: |

Water in excess of requirement causes the coarse aggregate to settle more and the water bleeds to top and evaporate leaving voids. This porous, weak concrete will be unable to bear shrinkage stresses without cracking. |

Water in excess of requirement causes the coarse aggregate to settle more and the water bleeds to top and evaporate leaving voids. This porous, weak concrete will be unable to bear shrinkage stresses without cracking.

Result in shrinkage cracks during or soon after the finishing because of moisture absorption by dry subgrade, dry forms, dry aggregates, or hot sunny weather.

Caused by different settlement of concrete particles and is a direct result of bleeding. |

|

Considered as a rare form of cracking, ASR is caused by mixture problem, when high alkali cements presence together with aggregates containing reactive forms of silica and water. |

For ASR, so far there is no effective repair technique for structures that are seriously affected. |

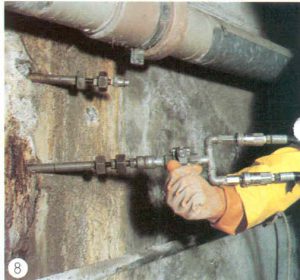

The corrosion of steel bars may cause cracks, delamination of concrete section and rust stains to appear in the concrete.

|

Extensive corrosion of reinforcement may result in the need to demolish the structure |

| 2. Crazing

This is resulted from differences moisture movement due to high moisture concentration gradient or a discontinuity in compaction near the exposed surfaces. The cracks are rarely exceed 12mm or so in depth, and are therefore nor serious, apart from unsightliness. |

To use an earthy-moist mix, or if plastic mix is necessary use as low as w/c ratio as is practicable and remove the cement skin to expose the aggregate. Troweling should be avoided as the surfaces are prone to crazing. |

| 3. Sulphate attack

This is caused by the presence of sulphate in the ground and movement of the moisture. It’s the most common cause of distortion, cracking and upward movement of concrete floor. The rate of sulphate attack is influenced by the permeability of concrete (which in turn is determined by mix design and QC on site); the concentration and types of soluble sulphate salts present; the presence of water and the pressure differences which may force the solution through the concrete. |

The slab must be broken out and removed, it should not be used as hardcore under the replacement (or any other) slab. The new slab should be laid on a DPM over the fill and turned up at the perimeter. |

| 4. Crystallization damage

Sulphate or other salts may be admitted by permeable concretes and if, at a later stage, drying occurs, these salts crystallize. The condition may be severe when concrete is subjected to wetting and drying cycles, or if one area of structure is saturated while the adjacent area is dry. Salts migrate toward the dry area, causing extensive crystallization in the region of drying. |

|

| 5. Efflorescence

This is the appearance of fluffy white patches on the surface. It is caused by poorly washed aggregate, salty water used in making concrete the salts being leaching out to the surface by rain water afterwards. As the water evaporates white patches appear on the surface. This defect can be controlled to some extend by coating the surface by a water repellent agent. |

Removed by scrubbing with water, or by hosing with water under high pressure. Dilute acids may be useful:

” 1 part hydrochloric acid in 9 to 19 parts water ” 1 part phosphoric acid in 9 parts water ” 1 part phosphoric and 1 part acetic acids in 19 parts water Concrete should be rinsed thoroughly with water after removal of efflorescence. |

Note: For more defects, please refer to the Defect Library.