Waterproofing

Property

Components Classification

Based on the characteristics and the basic material, waterproofing systems can be generally classified into 3 main categories, namely:

Preformed membrane/ Sheet/ Roll

This type is suitable for large area with minimum protrusions, thus in Singapore it is not commonly used in the internal wet area. It is practicable to be used in area such as concrete bridges, flat roof, basement and tunnels. It’s either self adhesive or bonding agent has to be used.

The base of this system can be either Bituminous (i.e. Asphalt, Bitumen, modified Bitumen) or Non Bituminous (i.e. Ethylene-Copolymer Bitumen (ECB), Polyvinyl Chloride (PVC), Polyethylene (PE), Chlorinated Polyethylene (CPE), Butyl Rubber, Ethylene Proplyene Diene (EPDM), Neoprene, Polysobutylene (PIB), and Bentonite clays.)

Liquid applied membrane

Liquid applied system are preferred to be used in the internal wet area, due to its continuity between horizontal and vertical planes, around projections and penetrations and some of them come in self-leveling property.

The base of this system can be either Bituminous or Non Bituminous (i.e. Acrylic, Epoxy, Polyurethane (PU), Polyisorene/ rubber, Cementitious, etc).

However, generally Liquid applied system can be classified into water based and solvent based.

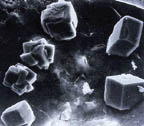

Integral waterproofing

Integral waterproofing usually refers to admixtures that are supposed to decrease the water permeability of structural concrete. This is not just a matter of concrete mix but also involves issues in structural design and the manner of handling of the concrete in the field. Detailing and lcation of joints and reinforcing steel as well as quality control in mixing, placing, curing, and finishing are more important to watertightness than adding waterproofing agents to the concrete mix.

It can be applied by brush (as coating), dry shake, or as admixture.

|  |  |

| Untreated Concrete | Initiation | Mature |

Density

Depending on the type of waterproofing, the density is ranged from 1.2-1.6 g/cm³.

| Preformed membrane | Generally quite dense and sometimes its self-weight may become a deterent factor due to creep when installed on vertical surfaces such as basement walls. |

| Liquid-applied | Generally low density. |

| Cementitious | Can be relatively dense due to the cement and aggregate contents |

Thermal Conductivity

- About 0.691 W/ m²K.

- As all waterproofing membranes are relatively thin ( 0.6 to 4 mm) thermal conductivity is normally insignificant and for roofs, this is usually provided by using a layer of insulation material such as extruded polystyrene, etc.

Water Vapour Transmission

Herewith is the general comparison between different types of waterproofing in terms of water vapour transmision:

| Preformed membrane | depending on the generic types ie bitumen based generally very low vapour permeablity while PVC types usuall are formulated with relative high vp. |

| Liquid-applied | as above except that vapour permeability is usually affected by the thickness of the membrane and liquid systems tend to have lower thickness therefore generally better vapour transmission. |

| Cementitious | good vapour permeability due to its structure |

The range of water vapour transmission value for different types of waterproofing system (for sheet membrane and liquid applied only):

| Self adhesive membrane (thk : ±1.5mm) | 5-15 g/m².24 hr |

| Bituminous membrane (torch on, thk:3-4mm) | 5-15 g/m².24 hr |

| Liquid applied roof waterproofing (thk: 0.8-1mm) | 40-80 g/ m².24 hr |

| Flexible cementitous membrane (thk: 0.8-1mm) | < 30 g/ m².24 hr |

| Elastomeric wall coating (thk: 0.2 mm) | > 80 g/ m².24 hr |

In SS 374: the WVT requirement is < 12g/m².24h.

If the amount of water vapour in the substrate is high and it has to permeate the film of low WVT, there will be a pressure on the film which can cause debonding from the substrate, resulting in blistering which is common among liquid applied roof coating.

For liquid applied elastomeric wall coatings, the specification is >80g/m².24h

Elastomeric wall coating have higher WVT due to the lower applied film thickness and therefore reduce the risk of debonding from the substrate, caused by the high pressure of water vapour.

Tensile Strength

Range about 4 – 6 N/mm²

| Types | |

| Preformed membrane | Generally high especially if reinforced. |

| Liquid-applied | Medium to low depending on generic types and also whether reinforced |

| Cementitious | Generally low tensile strength and normally not reinforced except at detailing. |

Modulus Elasticity (elongation at break)

| Types | |

| Preformed membrane | Generally good for non-reinforced. Elongation however is affected by types of reinforcements (range 50 to 1000%). |

| Liquid-applied | Average from medium to high depending on generic types (range 50 to 700%) ie.

|

| Cementitious | Low, normally at around 150 % for polymer modified type. |

Reinforcement

| Base reinforcements | Benefits | Limitations |

| Woven glass fibre tissues and mats |

|

|

| Glass / polyester ( mixed non-woven fibres ) |

|

|

| Polyester |

|

|

| Property | APP modified | SBS modified | SS 374 : 1994 requirements | ||

| Nominal thickness in mm. include surfacing | glass* | polyester** | glass* | polyester** | |

| Dimension stability

(both longitudinal & transverse)%. | 4 mm | 4 mm | 4 mm | 4 mm | – |

| Tensile strength, longitudinal (N/mm2)

transverse (N/mm2) | 0.1% | + 0.14% – 0.10 % | 0.2% | 0.3% | + 0.5 % – 0.5 % |

| Elongation at break, longitudinal (%) transverse ( % ) | 2 % 2 % | 45% 45% | 2 % 2 % | 45% 45% | both max min 45 % |

| Tear strength / shear, longitudinal (N/mm) transverse ( N /mm) | 80 100 | 175 210 | 110 130 | 180 220 | Tensile shear at joints –

failure occur outside ( > 500 N.) |

| Water absorption, ( % ) | 0.5 % | 1.3 % | – | – | < 1.0 % |

| Vapour penetration resistance | 40,000 | 46,000 | 70,000 | 50,000 | Water vapour transmission in g. / hr-m2(< 0.5) |

| Hydrostatic test | 2 bars | 2 bars | 2 bars | 2 bars | > 3 bars – no leakage observed |

| Low temperature flexibility, max. ºC | – 15 | – 18 | – 25 | – 25 | NA |

| Heat resistance, max. ºC | +130 | +155 | +100 | +100 | NA |

*glass fibre 50 gm./m²

**polyester mat 180 gm./m²

| Property | PVC* | EVA** | ECB*** | SS 374 : 1994 |

| Membrane thickness mm | 1.2 | 1.2 | 2.0 | |

| Dimensional stability %

longitudinal |

0.0 |

< 0.4 |

< 1.0 |

±2.0 % without ageing |

| Tensile strength ( max ) in N / mm² longitudinal transverse |

15.4 |

12.5 |

6 |

> 15.0 N/mm2 |

| Elongation at break %

longitudinal |

250% |

320% |

350% |

>300% |

| Vapour permeability coefficient. | <15,000 | <20,000 | <80,000 | |

| Water vapour transmission. g/m2.24hr. | 11.4 | 1.65 | 0.25 | vapour transmission < 12 g/m2.24hr. |

| Water absorption after 24 hours %. | 0.11 | NA | 0.31ª | < 1.0 % |

| Resistance to water penetration | 4 bars | 4 bars | 6 bars | > 3 bars – no leakage observed |

| Low temperature flexibility °C | – 30 | – 20 | – 20 | |

| Root resistance | tested | NA | tested |

* PVC membrane reinforced with polyester scrim

** ECB membrane glass fleece backing

*** EVA membrane non-reinforced

ª water absorption after 7 days

| Property | EPDM | CSPE | SS 374 : 1994 |

| Membrane thickness in mm | 1.2 | 0.9 | |

| Dimensional stability %

longitudinal transverse |

±2 – |

< 0.4 0 | ±2.0 % without ageing |

| Tensile strength ( max ) in N / mm² longitudinal transverse |

11.7 |

10.4 |

> 15.0 N/mm2 |

| Elongation at break %

longitudinal |

475% |

500%* |

>300% |

| Water vapour transmission. g/m2.24hr | 0.25 | 2.1 | vapour transmission < 12 g/m2.24hr. |

| Water absorption after 7 days. % | 2.0 | 1.25 | < 1.0% after 24 hours |

| Low temperature flexibility °C | – 65 | – 45 |

* Elongation of rubber only, fabric elongation at 35%.

Recommended Testing Method

Applicable for cementitious membrane waterproofing:

| Item | Test method | Specification |

| Characterization of Polymer | FTIR, DTA & TGA | FTIR, DTA & TGA graphs used as fingerprint records for future comparison of subsequent testing |

| Initial hardness (Shore A) * 7 days curing | ASTM D2240 | min 40 |

| Crack bridging | ASTM C836 | No cracking at 2mm width No crack after 10 cycles of stretching & closing at 1mm width |

| Adhesion to substrate * Condition as cast | ASTM D4541 | min 0.3 N/mm2 |

| Tensile strength a) Condition as cast Change in strength (%) b) After ageing at 50ºC for 14 days c) After 72h chemical immersion at room temperature: i) 0.5% (v/v) NaOCl ii) 1.25% (v/v) NH4OH iii) 3.7% (v/v) HCl | ASTM D412 | min 1.5 N/mm2

min 1.3 N/mm2

} |

| Elongation a) Condition as cast Change in elongation (%) b) After ageing at 50ºC for 14 days c) After 72h chemical immersion at room temperature: i) 0.5% (v/v) NaOCl ii) 1.25% (v/v) NH4OH iii) 3.7% (v/v) HCl | ASTM D412 | min 150%

min 120%

} |

| Chloride Content | ISEA Method | min 0.1% |

| Resistance to water penetration | Adopted DIN 1048 : Pt 5 | No water penetration allowed at 0.2kgf/cm² for 6 hours |

| Set to touch time RH 65 ± 5% & 30 ± 2ºC | ASTM D1640 | Touch dry within 2 hours |