Structural Sealants

Defect and Repair

|

Sealants

|

Defect

|

Repair

|

Glass

Natural Stone |

Adhesion failure The loss of bond between the sealant and substrate.

| Use / select the right type of primer. Perform adhesion test initially. Apply proper amount of primer.

Mix 2 Component, sealant completely. Do not use tooling aids. Use proper solvent such as white spirit on polyester powder paint |

|

Cohesive & adhesive failure | Follow manufacturer recommendation for joint design and dimension. Use products with proper movement capability. Minimize the thickness of sealant.

Repair by using band-aid joint. Use proper bond breakers and backer rods |

|

Sealant hardening and crazing Hardening of the sealant leads the formation of crazing. This is brought about by the loss of solvent or plasticizers and by the action of ultra-violet radiation and ozone. | Select the right type of sealant that can be used externally.

Remove existing, clean and chaulk with suitable sealant |

|

Streaking The accumulation of airborne particulates in areas where fluid has migrated from the sealant onto non-porous substrates and forms discreet channels on the building façade. | Select the right type of sealant for the substrate.

If available, ask for staining test. Most poly-urethane sealants are non-staining to porous substrate. |

|

Cracking Hardening of the sealant leads the formation of cracking. This is brought about by the loss of solvent or plasticizers and by the action of ultra-violet radiation and ozone. | Select the right type of sealant that can be used externally.

Remove existing, clean and chaulk with suitable sealant |

|

Sealant waisting Viscous flow finally leads to thinning of the sealant in a part of the joint. | Select the right type of sealant that can be used externally.

Remove existing, clean and chaulk with suitable sealant |

|

Sealant staining The migration of fluids (plasticizers, unreacted or unreactive polymers, antioxidants, or other liquid formulation additives) out of a sealant and into a porous or microporous substrate causing a dark band (“wet look”) around the joint. | Select the right type of sealant for the substrate.

If available, ask for staining test. Most poly-urethane sealants are non-staining to porous substrate. |

|

Sealant debounding

| To take off the affected area and reapply |

see: https://codeconcrete.com/the-ultimate-guide-to-backer-rods/

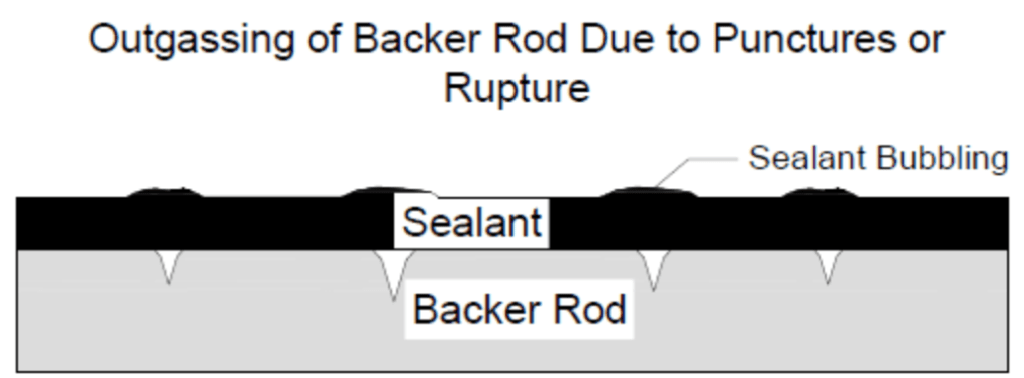

| Backer rod outgassing (Bubbling) Internal Pressure within the closed cell backer rod is released during backer rod installation due to puncturing. Sealant immediately applied will show bubbles and poor aesthetics | Direct the cut surface of the back-up materials towards the inside when installing.

Use the back-up materials of open cell.

|

Note: A standard test in a laboratory is recommended in advance of installation to evaluate:

| adequacy of adhesion of sealant to substrate and other sealant type | ASTM C 794 |

| possibility of sealant causing staining to certain substrates | ASTM C 1248 |

| compatibility of sealant with gasket, spacer, setting blocks, etc | ASTM C 1087 |

See Section 4.9.4 of Reference [2] for more details.