Concrete Spalling

Introduction

Type of Building: Commercial

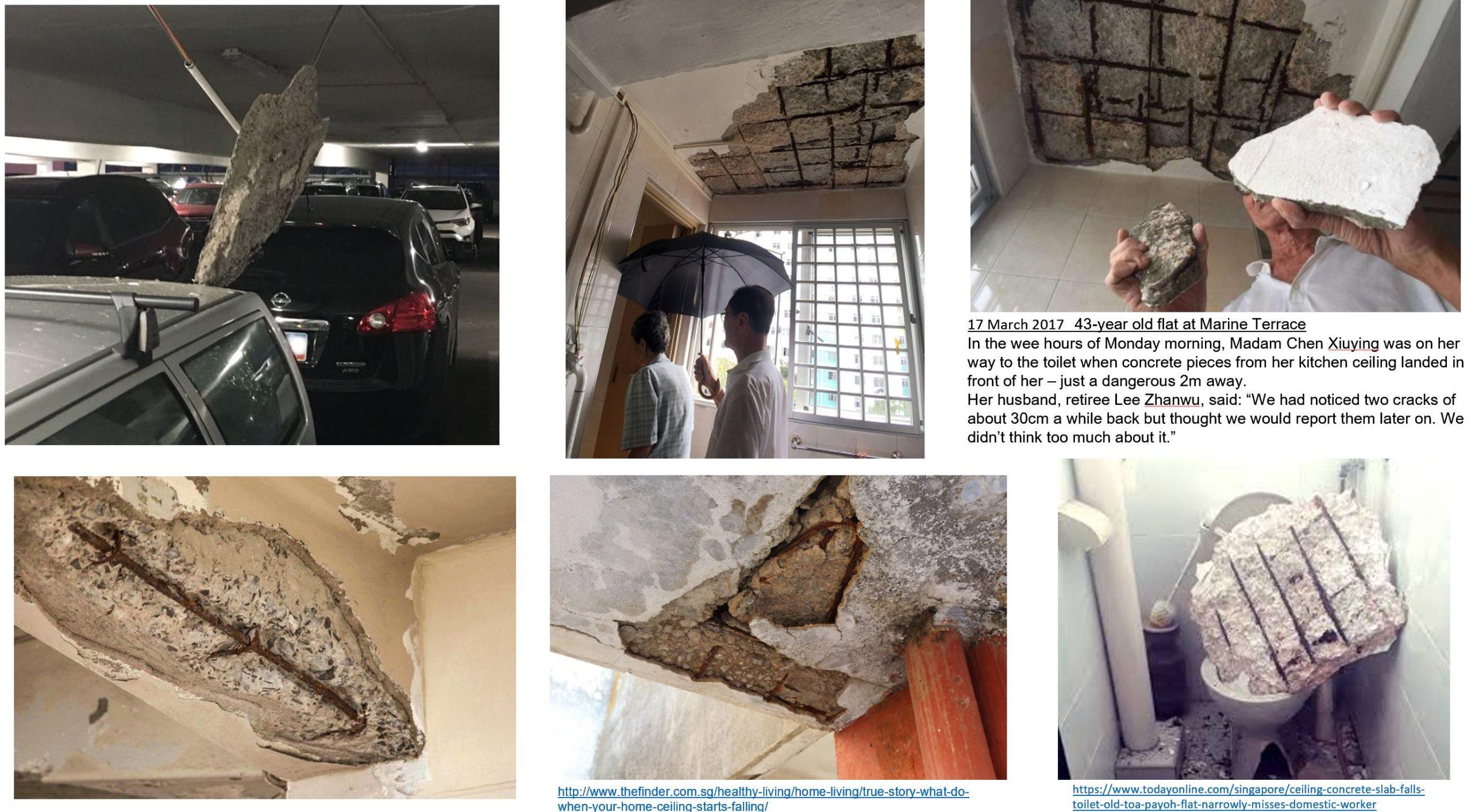

The ceiling had spalled over multiple areas and they are located near to some of the previous repaired spots, as seen by the injection markings. Reinforcement bars revealed are corroded and there were also efflorescence stains appearing around the spalled areas, indicating some recurring water leakage problem.

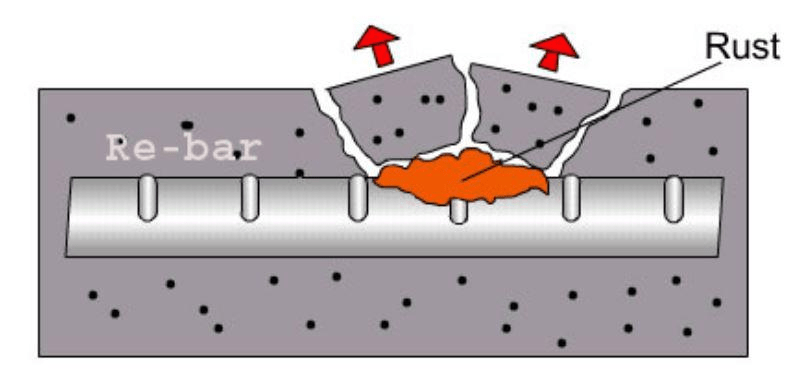

Corrosion of the steel produces iron oxides and hydroxides, which have larger volume than its original metallic iron volume. This increase in volume (approximately 5 times) develops tensile bursting stresses around reinforcement bars. As concrete is weak in tension, these stresses will cause cracking in concrete.

Corrosion is an electrochemical process, in which the following reactions are taking place to produce rust. Once rust film forms, its porous surface acts as a reservoir for liquids, which in turn causes further corrosion. If this process is not arrested, it would continue until the iron is entirely consumed by corrosion. In this case, corrosion has been spread until the surface (anode zone) is entirely damaged.

Cause of Defects

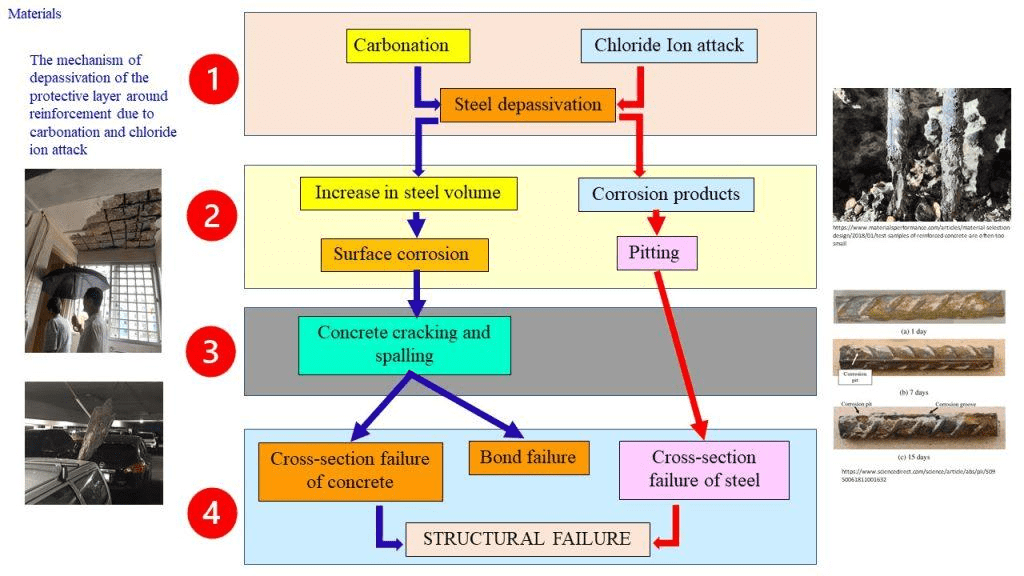

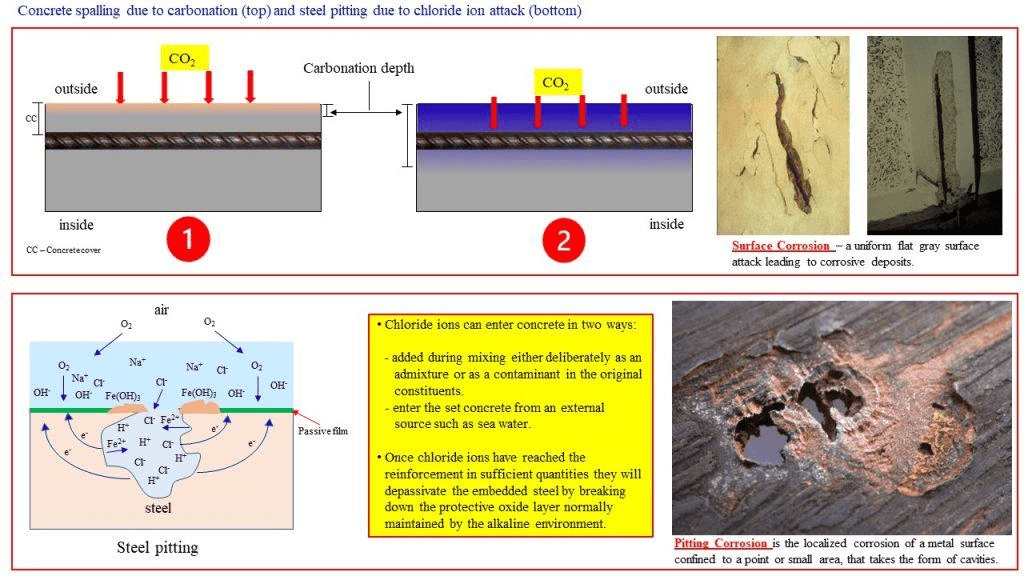

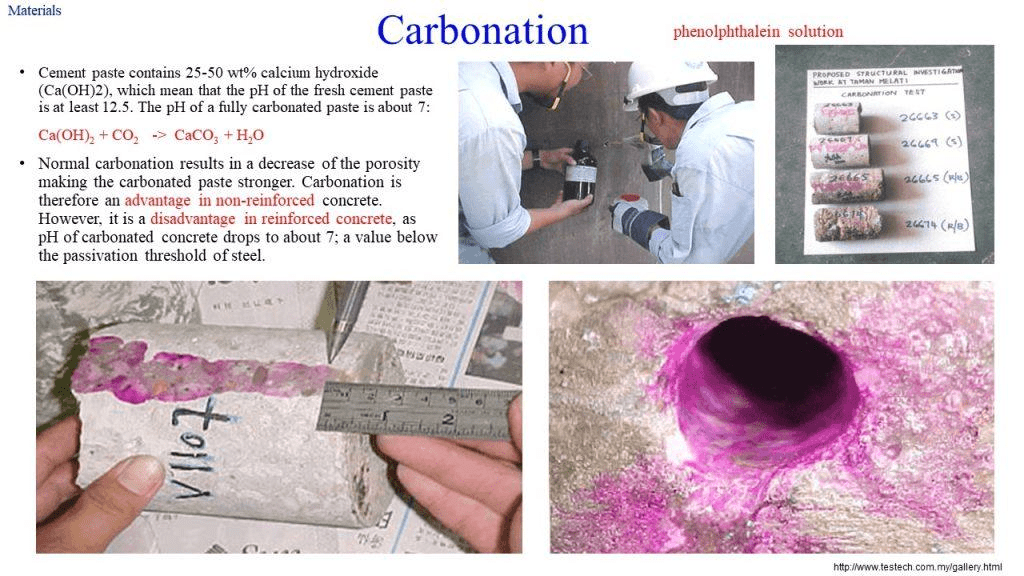

Concrete may be carbonated by the carbon dioxide from vehicle exhaust. Thus, the alkaline protective environment of the concrete is removed and corrosion begins. Due to the increase in volume of rebars from the formation of rust, corrosion of rebars and spalling of concrete may result.

Honeycombs in the concrete structure or lack of concrete cover may accelerate this carbonation process.

Concrete may be carbonated by the carbon dioxide from vehicle exhaust. Thus, the alkaline protective environment of the concrete is removed and corrosion begins. Due to the increase in volume of rebars from the formation of rust, corrosion of rebars and spalling of concrete may result.

Honeycombs in the concrete structure or lack of concrete cover may accelerate this carbonation process.

The high alkalinity of Ca(OH)2 is good in the case of preventing reinforcement corrosion, as the calcium hydroxide solution forms a protective passivating layer around the reinforcement with an alkaline environment of pH up to 13. This alkalinity, however, can be destroyed by carbonation, where

Ca(OH)2 + CO2 → CaCO3 + H2O

or through the addition of chloride ions, which could enter concrete either (i) as an added component during mixing, deliberately included as an admixture, or (ii) as an external agent, e.g., seawater or breeze entering the already set concrete.

Good Practices

Design

Adopt SS EN 1992-1-1, SS EN 1992-1-2, CP 65-1 or equivalent for the design of concrete. (SS 652: A.1.1.1)

Specify admixtures (e.g., water-reducing agent, pozzolanic products, pore refiner, etc.) to reduce permeability. Alternatively, for corrosion control in special areas with a high risk of water penetration, an electrochemical treatment can be specified; a process where electrochemical drying of concrete occurs by passing a current through the reinforcement, similar in principle to cathodic protection in accordance with BS EN 1504-9 or equivalent.

Construction

For the construction of basements, refer to the guidelines and provisions stipulated in BS 8004, EN 1997 or equivalent. Maintain water-cement ratio and the recommended aggregate grading during basement construction. Verify aggregate quality in accordance with ASTM C33/C33M-16e1 or equivalent. Use corrosion-resistant bars and corrosion inhibitors. Apply proper vibration (compaction) and curing. Consider concrete sealing to avoid exposing the aggregate in concrete work (mitigate pitting, scaling, spalling, powdering or chalking of concrete).

Concrete

Design

- Use good quality concrete:

- Cement: Portland cement blended with fly ash and slag to increase permeability

- Aggregate: Rust, silt, clay and sea-salt free. Chlorides in sand <0.06%; chlorides in coarse aggregates <0.03%; sulphates in aggregates <0.4%

- Water: pH< 6; sulphate content <1000 ppm; chloride content <500 ppm

- Concrete mix: cement content < 420 kg/m3; water-cement ratio < 0.45

- Ensure that the concrete cover provides sufficient protection against carbonation:

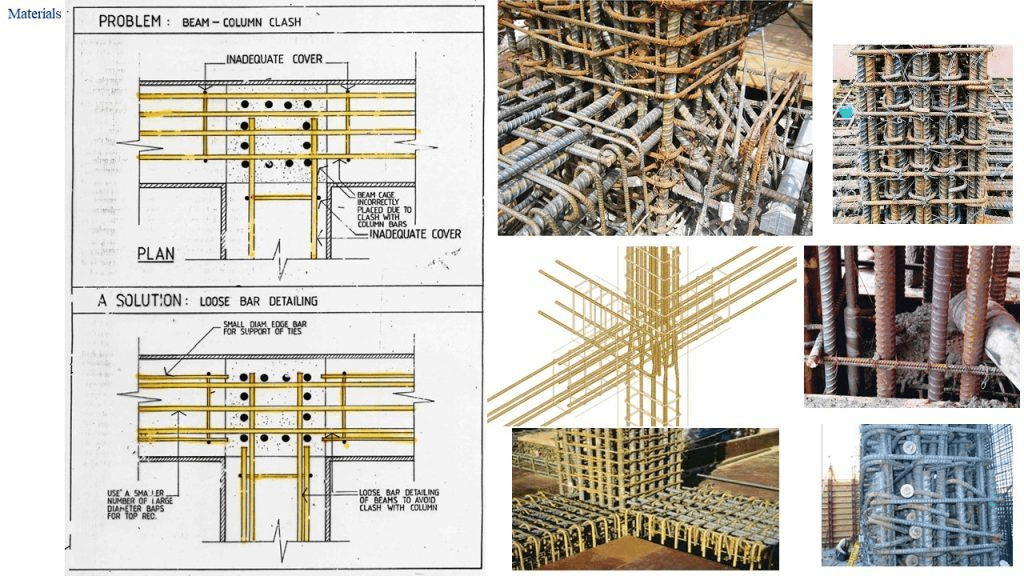

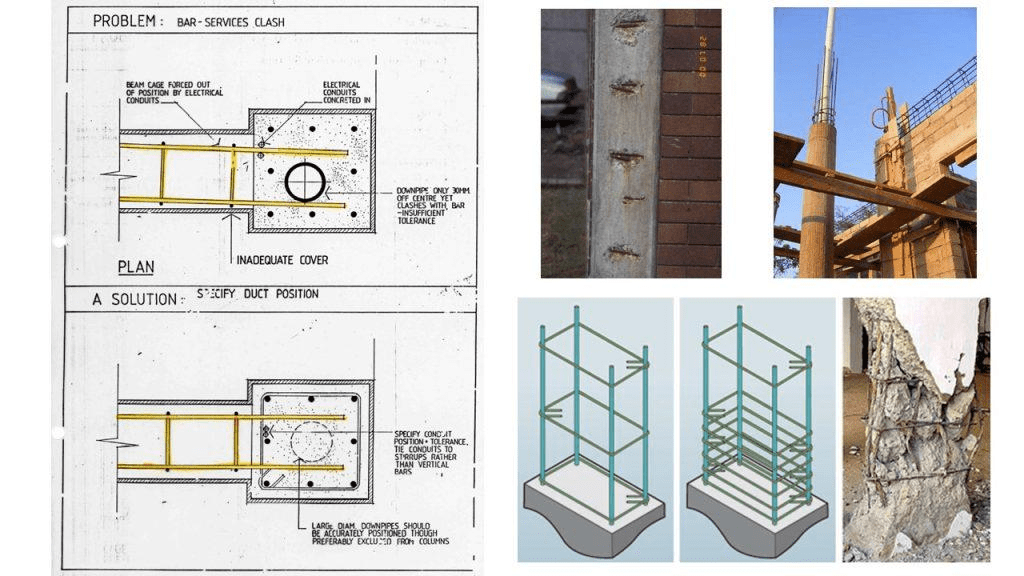

Material

Cement should comply with SS EN 197 series while coarse and fine aggregates used should comply with SS EN 12620. All aggregates shall be stored in clean places. Table 2 shows the various concrete grade to be achieved.

| Concrete Grade | 30 | 35 | 40 | 45 | 50 |

| Minimum cement content (kg per m3) | 275 | 300 | 325 | 350 | 400 |

| Maximum cement content (kg per m3) | 550 | 550 | 550 | 550 | 550 |

| Maximum % of Fine Aggregate to Total Aggregate | 50 | 50 | 50 | 50 | 50 |

| Maximum water to cement ratio | 0.55 | 0.50 | 0.45 | 0.40 | 0.40 |

Construction

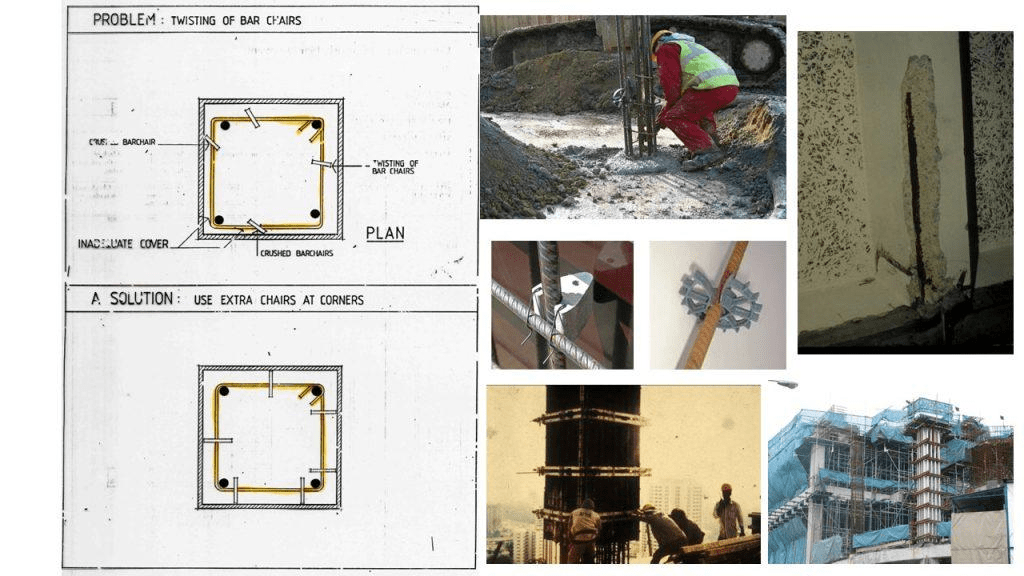

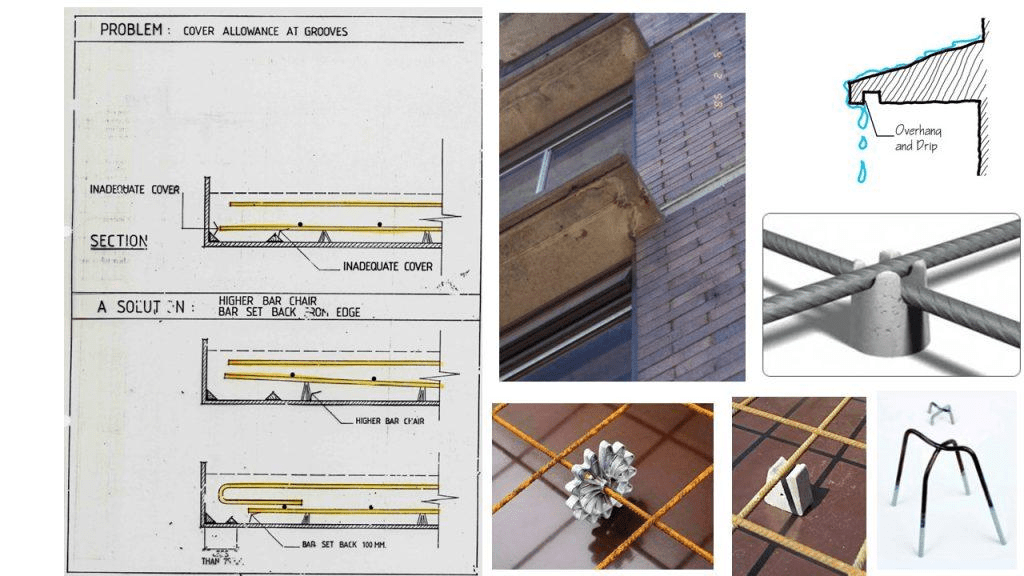

To ensure sufficient concrete cover, concrete spacers or bar chairs.

Reinforcement bars can be protected further by:

1. use of non-metallic coatings such as epoxy coatings or cement based coatings

2. use of metallic coatings such as Zinc and Nickel

3. Cathodic protection

4. use of corrosion inhibitors

5. use of corrosion resistance reinforcement (eg. stainless steel)

Ensure thorough compaction of the concrete during placement to obtain dense concrete minimizing carbonation.

Quality Control

Check for the quality of concrete before placing. e.g. water cement ratio, slump test, etc.

Check for the correct concrete cover thickness.

Reinforcement

Design

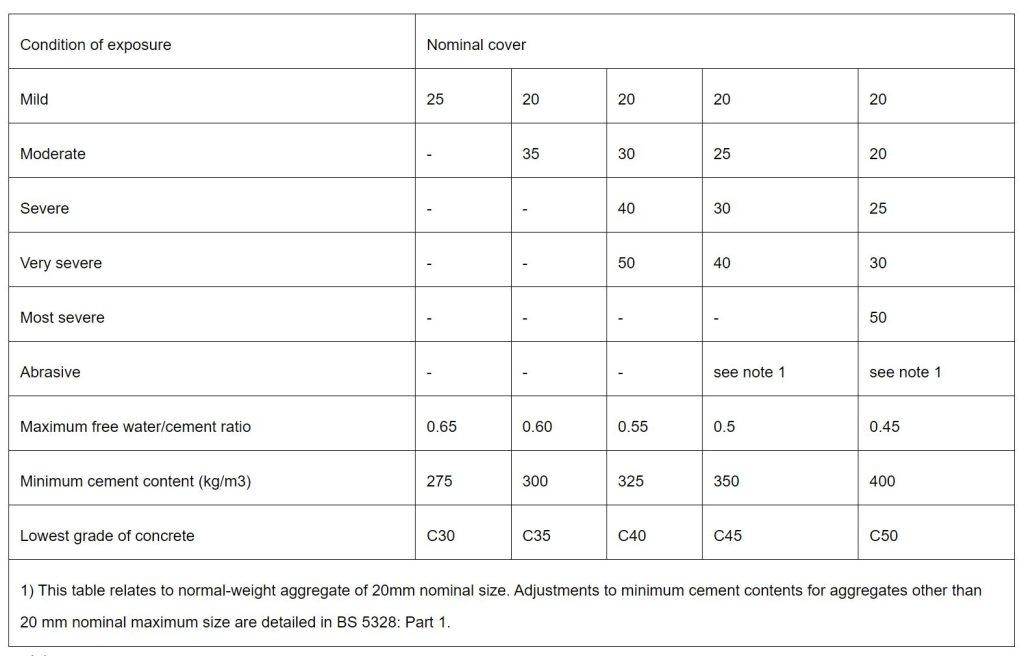

Sufficient concrete cover should be provided to prevent corrosion of reinforcement.

| Condition of exposure | Nominal cover | ||||

| Mild | 25 | 20 | 20 | 20 | 20 |

| Moderate | – | 35 | 30 | 25 | 20 |

| Severe | – | – | 40 | 30 | 25 |

| Very severe | – | – | 50 | 40 | 30 |

| Most severe | – | – | – | – | 50 |

| Abrasive | – | – | – | see note 3 | see note 3 |

| Maximum free water/cement ratio | 0.65 | 0.60 | 0.55 | 0.5 | 0.45 |

| Minimum cement content (kg/m3) | 275 | 300 | 325 | 350 | 400 |

| Lowest grade of concrete | C30 | C35 | C40 | C45 | C50 |

| 1) This table relates to normal-weight aggregate of 20mm nominal size. Adjustments to minimum cement contents for aggregates other than 20 mm nominal maximum size are detailed in BS EN 206+A2. |

Material

All high yield reinforcement bars should comply with SS 2 and welded steel fabric should comply with SS 32 [7]

Reinforcement can be protected further by using following methods:

- removal of rust and mill scale before embedment

- use of non-metallic coatings such as epoxy resins and solvent containing acrylic resins [9]

- use of metallic coatings such as zinc and nickel

- Cathodic protection

- use of corrosion inhibitors

- use of corrosion resistance reinforcement (eg. stainless steel)

- use of low permeability concrete, with improved resistance to chloride ion ingress

Standards

Concrete

BS EN 197-1 Cement. Composition, specifications and conformity criteria for common cements

BS ISO 3310-2 Test sieves. Technical requirements and testing. Test sieves of perforated metal plate/ BS 410-1, ISO 3310-1 Test sieves. Technical requirements and testing. Test sieves of metal wire cloth

BS EN 12620 Aggregates for concrete

BS EN 12878 Pigments for the colouring of building materials based on cement and/or lime. Specifications and methods of test

BS 4550-6 Methods of testing cement. Standard sand for mortar cubes

BS EN 1015-7 Methods of test for mortar for masonry. Determination of air content of fresh mortar / BS EN 1015-4 Methods of test for mortar for masonry. Determination of consistence of fresh mortar (by plunger penetration) / BS EN 1015-19 Methods of test for mortar for masonry. Determination of water vapour permeability of hardened rendering and plastering mortars / BS EN 1015-1 Methods of test for mortar for masonry. Determination of particle size distribution (by sieve analysis) / BS EN 1015-2 Methods of test for mortar for masonry. Bulk sampling of mortars and preparation of test mortars / BS EN 1015-3 Methods of test for mortar for masonry. Determination of consistence of fresh mortar (by flow table) / BS EN 1015-6 Methods of test for mortar for masonry. Determination of bulk density of fresh mortar / BS EN 1015-9 Methods of test for mortar for masonry. Determination of workable life and correction time of fresh mortar / BS EN 1015-10 Methods of test for mortar for masonry. Determination of dry bulk density of hardened mortar / BS 4551 Mortar. Methods of test for mortar and screed. Chemical analysis and physical testing / BS EN 998-1-Specification for mortar for masonry. Rendering and plastering mortar/ BS EN 998-2-Specification for mortar for masonry. Masonry mortar

BS EN 934-3 Admixtures for concrete, mortar and grout. Admixtures for masonry mortar. Definitions, requirements, conformity and marking and labelling/ BS EN 480-4 Admixtures for concrete, mortar and grout. Test methods. Determination of bleeding of concrete/ BS EN 934-6 Admixtures for concrete, mortar and grout. Sampling, conformity control and evaluation of conformity/BS EN 480-11 Admixtures for concrete, mortar and grout. Test methods. Determination of air void characteristics in hardened concrete/BS EN 480-12 Admixtures for concrete, mortar and grout. Test methods. Determination of the alkali content of admixtures/BS EN 480-1 Admixtures for concrete, mortar and grout. Test methods. Reference concrete and reference mortar for testing/BS EN 934-2 Admixtures for concrete, mortar and grout . Concrete admixtures. Definitions, requirements, conformity, marking and labelling/BS EN 480-8 Admixtures for concrete, mortar and grout. Test methods. Determination of the conventional dry material content/BS EN 480-10 Admixtures for concrete, mortar and grout. Test methods. Determination of water soluble chloride content/BS EN 480-6:2005 Admixtures for concrete, mortar and grout. Test methods. Infrared analysis/BS EN 480-5:2005 Admixtures for concrete, mortar and grout. Test methods. Determination of capillary absorption/BS EN 480-2:2006 Admixtures for concrete, mortar and grout. Test methods. Determination of setting time

BS EN 998-2 Specification for mortar for masonry. Masonry mortar/ BS EN 998-1 Specification for mortar for masonry. Rendering and plastering mortar

BS 6319-3 Testing of resin and polymer/cement compositions for use in construction. Methods for measurement of modulus of elasticity in flexure and flexural strength

BS 6319-12 Testing of resin and polymer/cement compositions for use in construction. Methods for measurement of unrestrained linear shrinkage and coefficient of thermal expansion

PD 6678 Guide to the specification of masonry mortar

BS EN 480-1 Admixtures for concrete, mortar and grout. Test methods. Reference concrete and reference mortar for testing

BS EN 480-2 Admixtures for concrete, mortar and grout. Test methods. Determination of setting time

BS EN 480-4 Admixtures for concrete, mortar and grout. Test methods. Determination of bleeding of concrete

BS EN 480-5 Admixtures for concrete, mortar and grout. Test methods. Determination of capillary absorption

BS EN 480-6 Admixtures for concrete, mortar and grout. Test methods. Infrared analysis

BS EN 480-8 Admixtures for concrete, mortar and grout. Test methods. Determination of the conventional dry material content

BS EN 480-10 Admixtures for concrete, mortar and grout. Test methods. Determination of water soluble chloride content

BS EN 480-11 Admixtures for concrete, mortar and grout. Test methods. Determination of air void characteristics in hardened concrete

BS EN 480-12 Admixtures for concrete, mortar and grout. Test methods. Determination of the alkali content of admixtures

BS EN 934-2 Admixtures for concrete, mortar and grout . Concrete admixtures. Definitions, requirements, conformity, marking and labelling

BS EN 934-6 Admixtures for concrete, mortar and grout. Sampling, conformity control and evaluation of conformity

BS 8000-0 Workmanship on construction sites. Introduction and general principles

Waterproofing

BS 8000-0 Workmanship on construction sites. Introduction and general principles

Concrete

ASTM C33 / C33M – 16 Standard Specification for Concrete AggregatesASTM C33 / C33M – 16 Standard Specification for Concrete Aggregates ASTM C33 / C33M – 16 Standard Specification for Concrete AggregatesASTM C87 / C87M – 10 Standard Test Method for Effect of Organic Impurities in Fine Aggregate on Strength of Mortar

ASTM C94 / C94M – 15b Standard Specification for Ready-Mixed Concrete

ASTM C109 / C109M – 16a Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens)

ASTM C115 / C115M – 10e1 Standard Test Method for Fineness of Portland Cement by the Turbidimeter

ASTM C125-13a Standard Terminology Relating to Concrete and Concrete Aggregates

ASTM C136 / C136M – 14 Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates

ASTM C150-07 Standard Specification for Portland Cement (Withdrawn)

ASTM C295 / C295M – 12 Standard Guide for Petrographic Examination of Aggregates for Concrete / ASTM C115 / C115M – 10e1 Standard Test Method for Fineness of Portland Cement by the Turbidimeter / ASTM C125-15b Standard Terminology Relating to Concrete and Concrete Aggregates / ASTM C150-07 Standard Specification for Portland CementASTM C295 / C295M – 12 Standard Guide for Petrographic Examination of Aggregates for Concrete / ASTM C305 – 14 Standard Practice for Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic Consistency

ASTM C348 – 14 Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars

ASTM C349 – 14 Standard Test Method for Compressive Strength of Hydraulic-Cement Mortars (Using Portions of Prisms Broken in Flexure)

ASTM C452 – 15 Standard Test Method for Potential Expansion of Portland-Cement Mortars Exposed to SulfateASTM C452 – 15 Standard Test Method for Potential Expansion of Portland-Cement Mortars Exposed to Sulfate

ASTM C490/C490M-11e1 Standard Practice for Use of Apparatus for the Determination of Length Change of Hardened Cement Paste, Mortar, and Concrete

ASTM C494 / C494M – 15a Standard Specification for Chemical Admixtures for Concrete

ASTM C597 – 09 Standard Test Method for Pulse Velocity Through Concrete

ASTM C642 – 13 Standard Test Method for Density, Absorption, and Voids in Hardened Concrete

ASTM C778 – 13 Standard Specification for Standard SandASTM C778 – 13 Standard Specification for Standard Sand

ASTM C805 / C805M – 13a Standard Test Method for Rebound Number of Hardened Concrete

ASTM C1038 / C1038M – 14b Standard Test Method for Expansion of Hydraulic Cement Mortar Bars Stored in Water

Waterproofing

ASTM D5295 / D5295M – 14 Standard Guide for Preparation of Concrete Surfaces for Adhered (Bonded) Membrane Waterproofing Systems

ASTM D5957 Standard Guide for Flood Testing Horizontal Waterproofing Installations

Concrete

AS 1012.1 Methods of testing concrete – Sampling of concrete / AS 1012.2 Methods of testing concrete – Preparing concrete mixes in the laboratory / AS 1012.3.1 Methods of testing concrete – Determination of properties related to the consistency of concrete – Slump test / AS 1012.3.2 Methods of testing concrete – Determination of properties related to the consistency of concrete – Compacting factor test / AS 1012.3.3 Methods of testing concrete – Determination of properties related to the consistency of concrete – Vebe test / AS 1012.3.4 Methods of testing concrete – Determination of properties related to the consistency of concrete – Compactibility index / AS 1012.3.5 Methods of testing concrete – Determination of properties related to the consistency of concrete – Slump flow, T500 and J-ring test / AS 1012.4.1 Methods of testing concrete – Determination of air content of freshly mixed concrete – Measuring reduction in concrete volume with increased air pressure / AS 1012.4.2 Methods of testing concrete – Determination of air content of freshly mixed concrete – Measuring reduction in air pressure in chamber above concrete / AS 1012.4.3 Methods of testing concrete – Determination of air content of freshly mixed concrete – Measuring air volume when concrete is dispersed in water / AS 1012.5 Methods of testing concrete – Determination of mass per unit volume of freshly mixed concrete / AS 1012.5 Methods of testing concrete – Determination of mass per unit volume of freshly mixed concrete / AS 1012.6 Methods of testing concrete – Determination of bleeding of concrete / AS 1012.8.1 Methods of testing concrete – Method for making and curing concrete – Compression and indirect tensile test specimens / AS 1012.8.2 Methods of testing concrete – Method for making and curing concrete – Flexure test specimens / AS 1012.13 Methods of testing concrete – Determination of the drying shrinkage of concrete for samples prepared in the field or in the laboratory / AS 1012.14 Methods of testing concrete – Method for securing and testing cores from hardened concrete for compressive strength / AS 1012.15 Methods of testing concrete – Method for the estimation of portland cement content of hardened concrete / AS 1012.16 Methods of testing concrete – Determination of creep of concrete cylinders in compression / AS 1012.17 Methods of testing concrete – Determination of the static chord modulus of elasticity and Poisson’s ratio of concrete specimens / AS 1012.18 Methods of testing concrete – Determination of setting time of fresh concrete, mortar and grout by penetration resistance / AS 1012.19.1 Methods of testing concrete – Accelerated curing of concrete compression test specimens – Hot water method / AS 1012.19.2 Methods of testing concrete – Accelerated curing of concrete compression test specimens – Warm water method / AS 1012.20 Methods of testing concrete – Determination of chloride and sulfate in hardened concrete and concrete aggregates / DR AS 1012.20.1 Methods of testing concrete – Determination of chloride and sulfate in hardened concrete and aggregates – Nitric acid extraction method / DR2 AS 1012.20.2 Methods of testing concrete – Determination of water-soluble chloride in aggregates and hardened concrete / DR2 AS 1012.20.2 Methods of testing concrete – Determination of water-soluble chloride in aggregates and hardened concrete / AS 1012.21 Methods of testing concrete – Determination of water absorption and apparent volume of permeable voids in hardened concrete / Methods of testing concrete – Determination of the drying shrinkage of concrete for samples prepared in the field or in the laboratory

AS 1012.10 Methods of testing concrete – Determination of indirect tensile strength of concrete cylinders (‘Brasil’ or splitting test)

AS 1012.18 Methods of testing concrete – Determination of setting time of fresh concrete, mortar and grout by penetration resistance

concreteAS 1379-2007/Amdt 1 Specification and supply of concrete – AS 1379 Specification and supply of concrete

AS 1478.1 Chemical admixtures for concrete, mortar and grout – Admixtures for concrete

AS 1478.2 Chemical admixtures for concrete, mortar and grout – Methods of sampling and testing admixtures for concrete, mortar and grout

AS 1478.2 Chemical admixtures for concrete, mortar and grout – Methods of sampling and testing admixtures for concrete, mortar and grout

AS 2350.12 Methods of testing portland, blended and masonry cements – Preparation of a standard mortar and moulding of specimens

AS 2350.13 Methods of testing portland, blended and masonry cements – Determination of drying shrinkage of cement mortars

AS 2350.14 Methods of testing portland, blended and masonry cements – Length change of cement mortars exposed to sulfate solution

AS 2550.15 Cranes – Safe use – Concrete placing equipment

AS 3600 Concrete structures

AS 3648 : Specification and methods of test for packaged concrete mixes

Concrete

SS EN 197 – 1 Cement – Part 1 : Composition, specifications and conformity criteria for common cement/ SS EN 197 – 2 Cement – Part 2 : Conformity evaluation

SS EN 12620 Specification for aggregates for concrete

SS EN 206 Concrete. Specification, performance, production and conformity/ SS 544 series – Concrete – Complementary Singapore Standard to SS EN 206-1

SS EN 934 – 1 Admixtures for concrete, mortar and grout – Common requirements/ SS EN 934 – 2 Admixtures for concrete, mortar and grout – Part 2 : Definitions, requirements – Concrete admixtures – Definitions, requirements, conformity, marking and labelling/ SS EN 934 – 6 Admixtures for concrete, mortar and grout – Sampling, conformity control and evaluation of conformity

Waterproofing

SS CP 82 – Code of practice- waterproofing of reinforced concrete buildings

Concrete

ISO 1920-3 Testing of concrete — Part 3: Making and curing test specimens

ISO 1920-1 Testing of concrete — Part 1: Sampling of fresh concrete

ISO 3766 Construction drawings — Simplified representation of concrete reinforcement

ISO 3893 Concrete — Classification by compressive strength

ISO 1920-4 Testing of concrete — Part 4: Strength of hardened concrete

ISO 4103 Concrete — Classification of consistency

ISO 4635 Rubber, vulcanized — Preformed joint seals for use between concrete paving sections of highways — Specification

ISO 6274 Concrete — Sieve analysis of aggregates

ISO 1920-5 Testing of concrete — Part 5: Properties of hardened concrete other than strength

ISO 1920-2 Testing of concrete — Part 2: Properties of fresh concrete

ISO 6782 Aggregates for concrete — Determination of bulk density

ISO 6783 Coarse aggregates for concrete — Determination of particle density and water absorption — Hydrostatic balance method

ISO 1920-10 Testing of concrete — Part 10: Determination of static modulus of elasticity in compression

ISO 7033 Fine and coarse aggregates for concrete — Determination of the particle mass-per-volume and water absorption — Pycnometer method / ISO 7033 Fine and coarse aggregates for concrete — Determination of the particle mass-per-volume and water absorption — Pycnometer method

Reinforcement

ISO 6934-1 Steel for the prestressing of concrete — Part 1: General requirements

ISO 6934-2 Steel for the prestressing of concrete — Part 2: Cold-drawn wire

ISO 6934-3 Steel for the prestressing of concrete — Part 3: Quenched and tempered wire

ISO 6934-4 Steel for the prestressing of concrete — Part 4: Strand

ISO 6934-5 Steel for the prestressing of concrete — Part 5: Hot-rolled steel bars with or without subsequent processing

ISO 6935-1 Steel for the reinforcement of concrete — Part 1: Plain bars

ISO 6935-2 Steel for the reinforcement of concrete — Part 2: Ribbed bars

ISO 6935-3 Steel for the reinforcement of concrete — Part 3: Welded fabric

Maintenance and Diagnostics

It is known that good quality concrete does not require extensive maintenance. However, due to external factors, it may develop some defects even before reaching its design life. Therefore, regular inspections should be carried out methodically at regular intervals to detect defects. A suitable checklist could be used to ensure comprehensive checks. Proper diagnosis of these defects is very important to select correct corrective maintenance. The following instruments and techniques can be useful in defect diagnostic process.

Regular inspection should be carried out in accordance with BS 8210 to identify defects and ensure repair work is carried out before associated damage can occur. Testing of concrete via depth of carbonation

should be carried out to identify possible corrosion of rebar in accordance with BS 1881-210 or via the

phenolphthalein method in accordance with BS EN 14630 or equivalent. Damaged concrete due to

corrosion of reinforced steel should be repaired and protected in accordance with BS EN 1504-9 or equivalent.

Diagnostics of Defect (see also NDT)

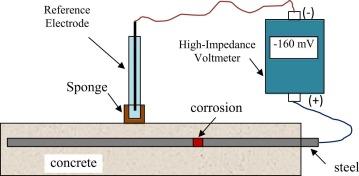

Half Cell Potential Measurement

The main application of Half cell measurement is to evaluate the probability of corrosion of the steel reinforcement embedded in the concrete members. This is measured in relation to the potential value readings.

Profometer (Covermeter) – rebar scanner

Profometers (covermeters), based on the principles of electromagnetism, are use to locate and to measure the depth of rebar (concrete cover).

Carbonation Test

The depth of carbonation in the freshly exposed surfaces of concrete can be determined by spraying with phenolphthalein indicator solution. In the case that pink colour appears, it means that the concrete still retains its alkaline nature and carbonation is minimal.

This test can be done in the laboratories as well as on sites.

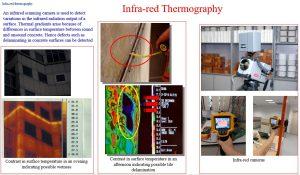

Thermography

Thermography can be used to identify the position of cracks. A range of crack widths, representing mechanical damage, has been induced under controlled laboratory conditions.

The method is based on the characteristics of heat flow phenomenon, in a conductive medium of specific geometry, which is intended to model predetermined boundary conditions. Thermo tracer is an advanced equipment used in thermograph technology.

Remedial (see also Remedial)

1. Repair of structural crack lines (Procedure of Surface Repair)

Surface repairs can be done on the floor slab if there are no signs of water seepage from underneath or widening of gap with time.

2. Polymer Modified Cementitious Grouting

This can be applied on the crack so that the final appearance of concrete structure closely resembles the concrete being repaired, in respect of strength and long term movement. Its characteristics are improved with regards to bonding, flexibility and time within which strength is gained.

3. Patching (Procedure of Patching)

This method is used to rehabilitate corrosion-damaged infrastructure, where the application of waterproofing membranes prevents, or at least retard, the ingress of chlorides to the reinforcement. However, when the chloride content in the concrete in contact with the rebars equals or exceeds the corrosion threshold, membranes will have no significant impact on reducing the level of corrosion.

The patching method is the most common repair method for minor concrete defects such as surface spalls. Two types of materials are commonly used for patching up by hand:

Cementitious mortars such as cement mortar and polyester-modified cementitious mortar.

Resin-based mortars such as epoxy resin mortar and polyester resin mortar.

4. Repair using epoxy injection (Procedure of Epoxy Injection)

One of the most versatile, crack repair method is epoxy injection.