Case 2

- Introduction

- Causes of Defects

- Good Practices

- Standards

- Maintenance and Diagnostics

- Remedial

- Similar Cases

- References

Maintenance and Diagnostics

Regular inspection is important in detecting or identifying the defects immediately. This is to ensure that corrective maintenance could be carried out at early stages so as to prevent further complexities. Visual inspection techniques or instrumentation techniques can be used for regular inspections.

Dust with a water-dampened cloth. If the surface is very soiled, wash with a solution of mild, non-abrasive detergent and warm water. Wring a cloth nearly dry and work on a small section at a time, then rinse with clear water. Dry the surface quickly before continuing. When fungi appear, remove them with a soft brush and bleach.

Periodic re-painting (about 5-7 years period) is necessary so as to keep the surface free from such peeling.

Diagnostics of Defect (see also NDT)

Visual Inspection

Peeling of paint is easily visible.

The following tests can be used to detect water seepage in structural floor:

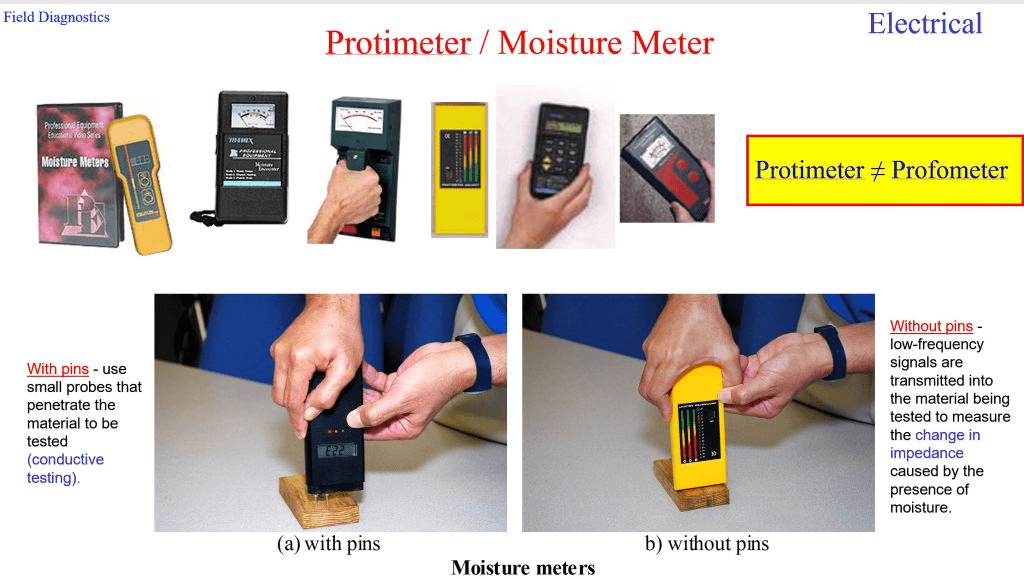

Hygrometer

Hygrometer can be used to test the amount of moisture present in the structure.

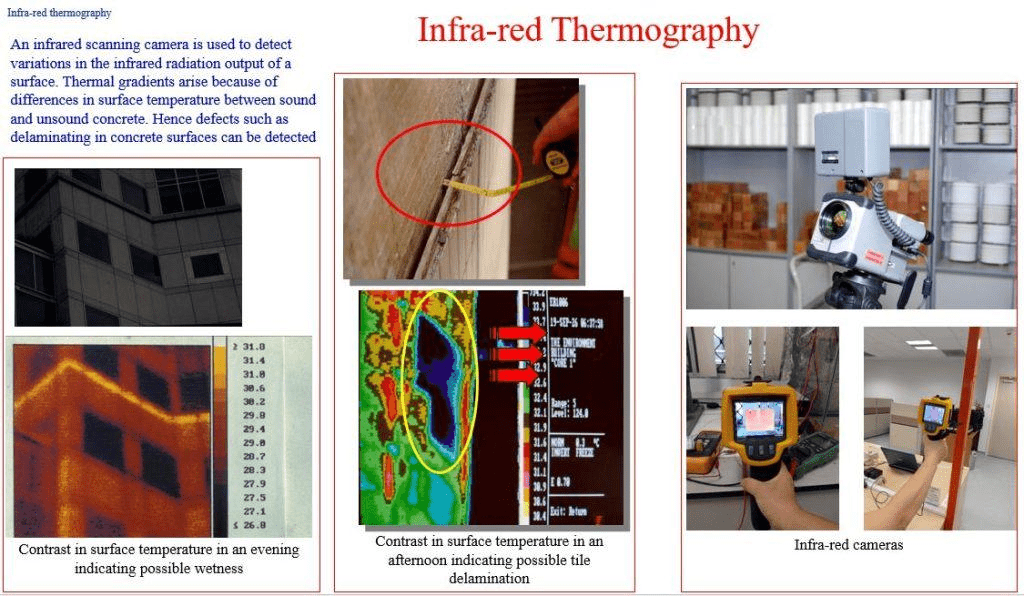

Thermography can be used to identify the position of cracks. A range of crack widths, representing mechanical damage, has been induced under controlled laboratory conditions. The method is based on the characteristics of heat flow phenomenon, in a conductive medium of specific geometry, which is intended to model predetermined boundary conditions.