Case 1

- Introduction

- Causes of Defects

- Good Practices

- Standards

- Maintenance and Diagnostics

- Remedial

- Similar Cases

- References

Maintenance and Diagnostics

Routinely inspect locations of pipe penetrations, such as service entries, which are particularly vulnerable

to water leakage. Keep access points clear and free from obstructions to avoid excessive hacking of finished surfaces (SS 652: A.9.2.1). Check for differential movement of the pipe in accordance with BS 8102, SS 637 (formerly CP 82) or other relevant and equivalent standards. (SS 652: A.9.2.2)

Periodic inspection and tests can be advisable to ascertain any other defects such as water leakages. Checklists could be used so that a thorough checking could be made. Defects could be recorded, monitored and not be left unattended.

Diagnostics of Defect (see also NDT)

This instrument is useful when services are concealed. There have been many cases of collapse of large area of false ceiling, due to weight of accumulation of water or condensate. Regular inspection using a fibrescope/borescope could prevent such accidents.

A fibrescope or a flexible borescope is a flexible optical inspection device that consists of fibre optic bundles with an eyepiece at one end and a lens at the other.

A fibrescope usually comes in two bundles: (i) a fibre optic light bundle that is for illuminating the object to be investigated, and (ii) a fibre optic image bundle to relay the image to the eyepiece. It allows a direct visual inspection for an otherwise inaccessible part, as observations of remote, difficult-to-reach areas can be made through a video monitor with high-resolution images. The flexible fibres allow it to be manoevred in hard-to-reach or inaccessible areas.

It is often used to verify findings from other tests, such as infrared thermography or impact-echo testing.

Common applications include:

– Inspection of connecting condition behind the external cladding wall of a building.

– Inspection of defects on concrete surface(s) in a deep and narrow gap.

– Determination of corrosion condition of steel tendon(s) inside post-tensioning ducts of pre-stressed structural member(s).

– Investigation of service pipes, ducts and other inaccessible areas.

Microwave tomography is a technique to measure the moisture of various materials based on the relatively high dielectric constant of “water” in comparison to the dielectric properties of the material. An electrical field (microwave) is applied to the material, and the microwave induces oscillations of bipolar molecules (i.e., water). Water molecules will reflect and absorb an electrical field during oscillations. A higher electrical field reflected indicates higher water content.

The technique is non-destructive and applicable to wood, brickwork and concrete. The uniqueness of this technique is its ability to measure moisture content at various depths up to 110 mm, allowing the plotting of a 3-D contour of moisture content and facilitating the tracing of the water source.

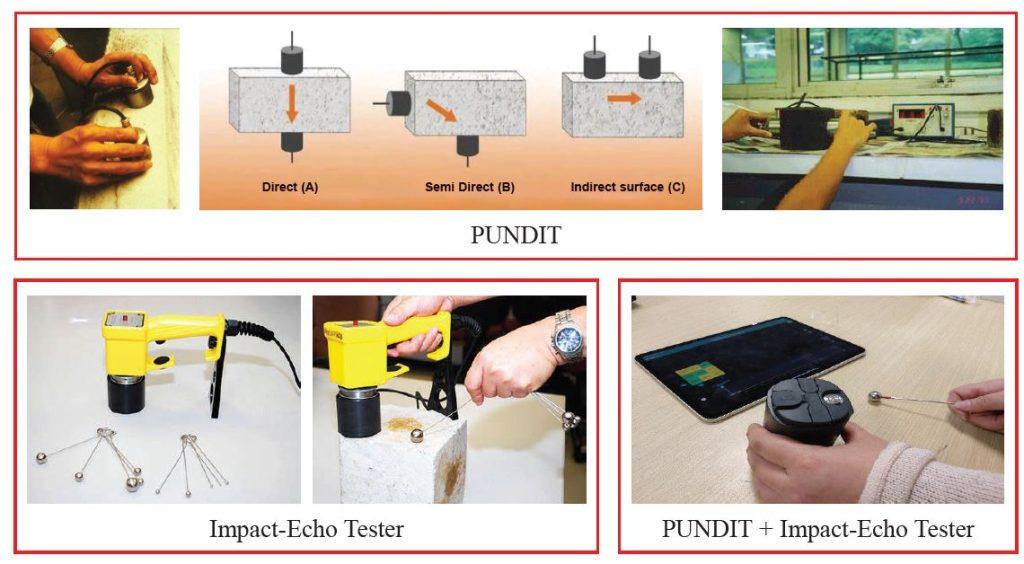

Ultrasonic Pulse Velocity (UPV)

UPV can identify non-homogeneous conditions such as voids, cracks and honeycombs using the optional hand-held terminal. This method can also be used to estimate the depth of cracks.

Thermography can be used to identify the position of water leakages. The method is based on the characteristics of heat flow phenomenon, in a conductive medium of specific geometry, which is intended to model predetermined boundary conditions. Thermo tracer is an advanced equipment used in thermography technology.