Case 1

- Introduction

- Causes of Defects

- Good Practices

- Standards

- Maintenance and Diagnostics

- Remedial

- Similar Cases

- References

Remedial (see also Remedial)

Find the source of water ingress, stop further water ingress using methods such as sealing, injection, impregnation (see Remedial). Establish the point where water penetrates beyond the tile and stop the water passage either by replacing the defective tile or by grouting the movement joint again. Epoxy injection may be the solution in lieu of removal and replacement. Apply silicone-based waterproof coating on the entire external wall (application of colourless water-repellent solutions to the wall where it is desired to retain its original appearance).

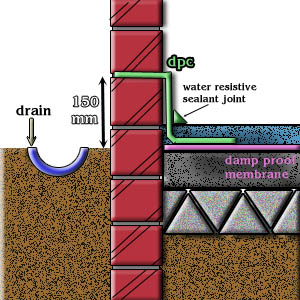

When diagnosed that the problem is rising dampness:

- The extent of rising damp will be identified with electronic moisture meters. Wall coverings, render etc. will be removed to expose masonry or brick work.

- Pressure injection along the identified damp course line will be done through drilled injection ports using specially designed pumps and lances to create a new damp proof course.

- A groove can also be cut into the brick wall and an aluminum sheet inserted to prevent the damp from rising up the wall.

- All rubbish and waste material will be removed.

- The growing mould on the wall surface should be removed by toxic wash using pressure jet of water and painted with waterproof (transparent solution of acrylic sealer or polyurethane) after the wall had dried out.

Removal of Efflorescence

-If efflorescence exists on an existing surface, the best method of cleaning or removing it, would be to use an acidic cleaner. These salts and minerals would readily dissolved in these acidic cleaning agents.

-Care should be taken when using these acidic agents which may be corrosive in nature.

-Occasionally, the cleaning and removal process can become more difficult if latex or chemical transmission occurs at the same time as the salts and minerals surfaced. These latex or comparable chemicals are often found in the more recent and advanced cementitious adhesives and grouts available and can form a protective layer which defends the efflorescence from direct contact with acidic cleaning products.

-To help solve this problem, select an acidic product that has cleaning agents in it (acid and cleaner in one single product). Another recommendation would be to use a high alkaline restoration cleaner to break down the latex protective coating, rinse well and then proceed with the acidic cleaning.

Treatment at joints

The composition of the grout or adhesive should be known when carrying out patch repair or re-grouting of joints to ensure that the repaired works can perform as it was originally designed for. For example, using inappropriate materials for re-grouting might lead to inability of the joint to accommodate movement, which might result in other defects such as cracking to surface.

Identifying the type and colour of the original grout poses a problem (above figure) as the grout changes colour over their useful life. Even if it is possible to correctly identify the grout, there is no guarantee the new grout will match perfectly; it may not even match at all after it is installed and allowed to cure and dry out.

Clean the surface using wire brush, high pressure water jet, grit blasting etc. according to the condition.

Repair: Application of Water Repeller

This type of solution act as a hydrophobic surface by penetrating into the pores of the bedding or screed layers and tightening the pores such that the water is not allowed to penetrate through.

It allows vapour to escape and prevent any development of hydraulic pressure caused by the retained moisture.

Repair: Application of Water Proofer (Silicate based)

This kind of solution reacts with the free lime in cementitious materials and seals the pores and cracks in the surface. In fact, as long as moisture and free alkali is present, the reaction will continue by sealing pores. This can also be referred to as “active” repair.

Repair: Application Water-based Clear Coating (with polymer particles)

In this treatment the floor is ponded with the solution and allow the super fine polymer particles to penetrate into the porous structure to form a permanent and continuous plug.