Case 3

- Introduction

- Causes of Defects

- Good Practices

- Standards

- Maintenance and Diagnostics

- Remedial

- Similar Cases

- References

Maintenance and Diagnostics

Periodic cleaning using a mild detergent or non-etching cleaning compound should be carried out ideally twice annually. The cleaning should be done from top down, with sufficient rinsing and drying after the cleaning. Cleaning should be uniform and localised excessive abrasive rubbing should be avoided. Light abrasive cleaning using compound with mild abrasive action is recommended every two to three years followed by sealing with protectant coat.

Maintenance

Inspections should be carried out to look out for signs of deterioration in aluminium framing in accordance with BS EN 13830, SS 654 or equivalent. Routine cleaning should be carried out to remove surface contaminants from metals in order to ensure maximum corrosion resistance of the metal. The

cleaning process chosen should be selected based on the type of contaminant, the recommended degree

of cleanliness, and cost in accordance with ASTM A380/A380M-17, BS EN 1993-1-4, BS EN ISO 12944-8 or equivalent. Special care should be taken in order not to damage the cladding surface during cleaning/maintenance.

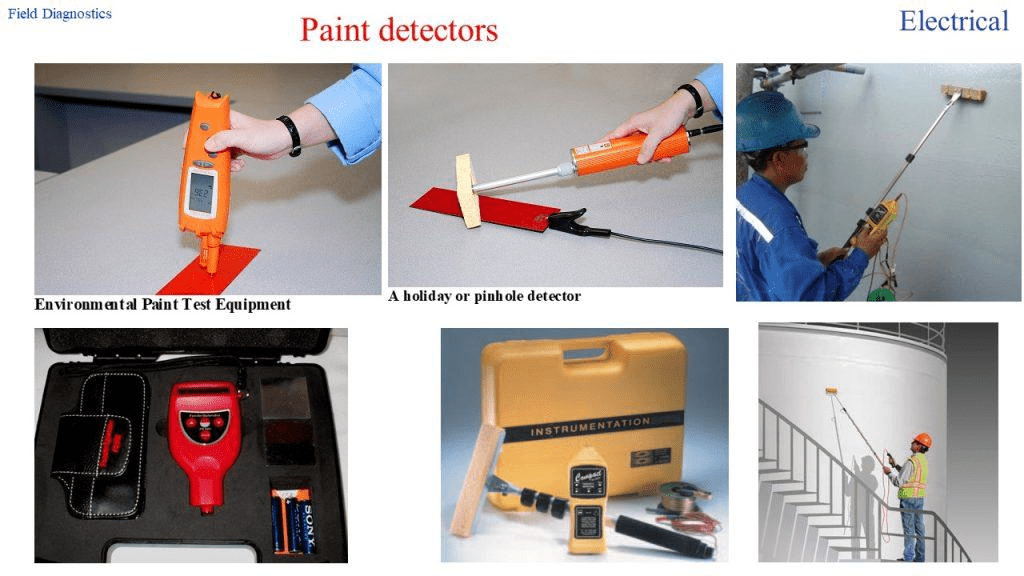

Diagnostics of Defect (see also NDT)

- Visual Inspection to identify the defect.

- The thickness of the coating can be measured with the ISOSCOPE MPO.

- An eddy current instrument can used to identify corrosion.

- Gloss meter to measure the glossiness.

Environmental and Holidays Test

-Connect the Probe to the dew meter

-Hold the dew meter in hand and point the probe to the surface to be measured

-Reading is taken off from the dewmeter

See also Staining of Facades