Case 3

- Introduction

- Causes of Defects

- Good Practices

- Standards

- Maintenance and Diagnostics

- Remedial

- Similar Cases

- References

Good Practices

- Logically, the easiest solution to prevent or minimize staining by ledges is to design façades without ledges or to put ledges on facades that receive little impacting rain. However, these would be too restrictive and impractical.

- A possible solution that is feasible to implement would be to increase the outward inclination of the ledge to more than 30o to the vertical. This would increase the rate of flow of runoff when it flows over the ledge onto the wall below. The runoff would then have a stronger washing effect.

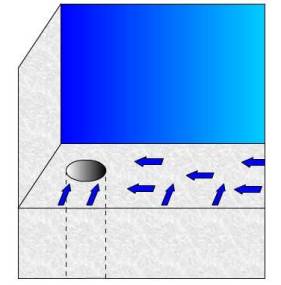

- The ledge could also be made to slope inwards so that runoff does not flow over the ledge but is retained at the ledge. The retained runoff can then be channelled into a drainage down pipe constructed within the façade system and be drained off in a controlled manner (Figure 1).

- The ledge could also be made to extend further beyond the general façade by way of attachment so that runoff is ‘thrown’ away from the façade. Together with a throating at the underside of the extended ledge, the runoff can be prevented from trickling back to the façade, hence minimising staining (Figure 2)

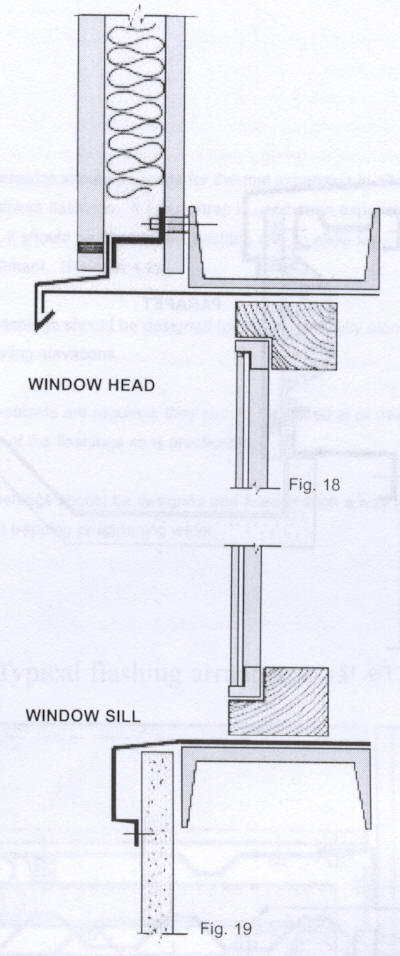

- The window head can also be made to be throated so that runoff from the top does not run against the window (Figure 3).

Design

Specify material and application methods for water repellence of porous masonry in accordance with BS 8221-2, SS 509-2 or equivalent. Throw off water from the façade altogether through an outward projecting sill or overhanging eaves (which incorporate a throat or drip lines on its underside) or provide blocking features such as copings/flashings. Use efficient scupper drains/downpipes to channel water down and away from the façade. To provide drip grooves along the underside of projecting features. Specify a paint system, which is permeable to avoid any paint defects which may cause staining.

Render the detailing for open joints as opposed to butt joints to avoid sealant staining. To use nonbleed sealants so as to prevent staining from silicone oil. Recommend joint designs, which are able to retain rainwater runoff within joints and expansion joints designated to provide vertical runoff carrying dirt down along the façade surface. Specify façade self-cleaning applications (e.g., TiO2, superhydrophobic

paint products, etc.) with due consideration given to site orientation, sunshades and protruding features. To understand the impacts of environmental, material, design and maintenance aspects on rainwater runoff.

See also Staining of Facades

Construction

Paint façade surfaces evenly with no patchiness. The finished texture should be uniform in colour. Ensure proper rendering to control surface granularity and local faults as it influences colour uniformity of the external façade in accordance with ISO 7361 or equivalent. Correct sealant applications to ensure consistent and continuous quality. Avoid misaligned panels of cladding in accordance with BS 8000-0 or equivalent. Refer to the planning of the painting programme, including inspection regime (initial and routine inspections) for buildings in accordance with BS 6150, SS 542 or equivalent.

Use self-cleaning coatings on newly built substrates for increased success in its performance. All construction/repair works on a façade surface should be done prior to application of a water repellent in accordance with BS 8221-2, SS 509-2 or equivalent. For serviceability of exterior façade surfaces, adopt ASTM E1667-95a or equivalent. It is important as it dictates the building’s individual and corporate identity. The correct application of TiO2 coating is crucial to ensure proper adhesion to the substrate. It is also challenging to check the proper application of the coating, especially on high-rise buildings, due to

its transparent property.