Case 3

- Introduction

- Causes of Defects

- Good Practices

- Standards

- Maintenance and Diagnostics

- Remedial

- Similar Cases

- References

Cause of Defects

The backing of the sealant must be properly formed with backer rod of appropriate diameter. The backer rod used was too small in diameter and thus cannot remain in place to provide a firm backing for the sealant. The backer rod was held in place with sealant but this solution can only physically allow the backer rod to be fixed inside the joints but did not solve the problem of non-rigid and non-uniformly leveled backing.

Foam Backer Rod Sizes and Shapes

When selecting a foam backer rod, it is crucial to choose the right size and shape based on the joint dimensions, sealant type, and environmental conditions. Below is a detailed breakdown of the sizes, shapes, and considerations for foam backer rods:

Foam backer rods come in various sizes to accommodate different joint widths. The sizes typically range between 5 to 75 mm in diameter, but the exact size needed depends on the joint size and type of backer rod used.

- Open Cell Foam: The diameter of the backer rod should generally be about 50% wider than the joint to ensure a tight fit. Open cell foam is more compressible and flexible, so it can be squeezed into joints that are slightly smaller than the rod diameter, creating a tight seal.

- Closed Cell Foam: For closed-cell foam backer rods, the diameter should be about 25-30% wider than the joint. Closed-cell foam is less compressible and retains its shape better, so it doesn’t require as much expansion as open-cell foam.

- Bi-Cellular Foam: For bi-cellular foam backer rods, the recommended diameter is about 25-50% wider than the joint. Bi-cellular foam combines the properties of both open and closed cells, offering a balance of flexibility and resistance to water absorption.

Outgassing of backer rod may have also contributed to the dislodge.

see: https://codeconcrete.com/the-ultimate-guide-to-backer-rods/

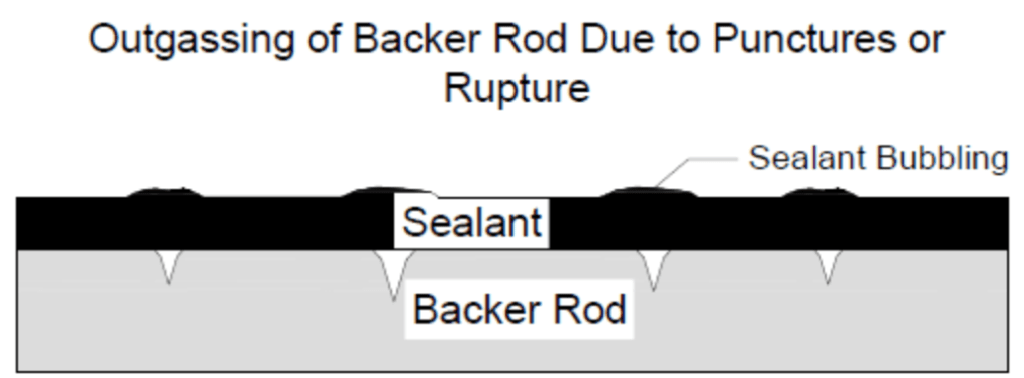

Outgassing is a phenomenon that occurs when air or gas, which is trapped within a foam backer rod (especially extruded closed-cell foam), escapes into the atmosphere. This is most often triggered by punctures or ruptures in the backer rod, which disrupt the internal structure of the foam. Here’s an in-depth look at the process and why it’s important to manage it:

In the production of closed-cell foam backer rods, air is injected into the foam material during the manufacturing process. This air becomes trapped within the individual cells of the foam. As the foam is compressed or manipulated during installation, the trapped air can remain contained within these closed cells. However, if the foam backer rod is punctured or damaged during installation or handling, the air inside the cells can escape. This release of gas is known as outgassing.

When this trapped air is released, it can create several issues, especially when fresh sealant or caulk is applied over the backer rod:

- Bubbling in the Sealant:

- The most immediate and visible issue caused by outgassing is the formation of bubbles or blisters in the sealant or caulk. As the air escapes from the punctured backer rod, it rises to the surface of the newly applied sealant, disrupting its smooth surface.

- These air pockets can cause gaps or voids in the sealant, leading to improper adhesion and ultimately compromising the sealant’s effectiveness.

- Uneven Curing:

- The release of gas can interfere with the curing process of the sealant, especially if the air escapes from the backer rod after the sealant has been applied. This disruption can cause inconsistent curing, leading to areas where the sealant is softer or less durable.

- In some cases, outgassing can prevent the sealant from adhering properly to the substrate or to the backer rod itself, reducing the overall lifespan of the joint seal.

- Reduced Sealant Performance:

- The presence of bubbles or gaps in the sealant due to outgassing can create weak spots in the joint, leading to water infiltration, dirt buildup, and other environmental factors that could eventually cause joint failure.

- Outgassing can also make it more difficult to achieve a smooth and uniform finish, which can be important for both aesthetic and functional reasons.

Outgassing from foam backer rods can cause significant issues with sealant application, including bubbling, poor adhesion, and reduced performance of the sealant. To avoid these problems, handle backer rods carefully during installation, choose the appropriate type of foam for the environment, and avoid puncturing the rod. By following these guidelines, you can ensure a smooth and effective sealing process that minimizes the risk of outgassing and maximizes the longevity and performance of your joint seal.