Case 1

- Introduction

- Causes of Defects

- Good Practices

- Standards

- Maintenance and Diagnostics

- Remedial

- Similar Cases

- References

Maintenance and Diagnostics

As buildings age the colour of paint will fade. Repainting and cleaning should be carried out regularly.

Maintenance

Consider availability of adequate water supply, drainage provisions and electrical power supply to choose a façade cleaning method. Records of cleaning operations (including photographs before and after cleaning, and drawings of nature of deposits, thickness and patterns) should be kept for buildings of significance in accordance with BS 8221-1, SS 509-1 or equivalent. Maintain the façade in a state as near as possible to its new condition. Ease of façade maintenance can be expressed by the frequency of necessary maintenance operations, labour and supplies necessary for each maintenance operation,

and number of possible ways of removing stains, graffiti, etc., or ISO 7361 or equivalent.

Detect/determine staining of porous substrates by joint sealants (ISO/NP 16938-1). Adopt the recommendations for treatments for controlling organic growth in accordance with BS 8221-2,

SS509-2 or equivalent. Repair painted surfaces damaged by wear and tear; wash down; remove defective

paint film; apply sealer/primer (if necessary); and repaint in accordance with BS 6150, SS 542 or equivalent. TiO2 only works where there is sunlight. Conventional cleanings are still needed for non-coated areas. For areas coated with TiO2, conduct

Periodic cleaning is necessary to maintain the aesthetics of tiled façades. A neutral cleaning agent should be adequate if a periodic maintenance schedule is performed.

Periodic monitoring of water moisture on the facade is required to prevent excessive water seepage into the facade.

Diagnostics of Defect (see also NDT)

Visual Inspection

Visual assessment evidence is brown staining that may had permeate to the concrete surface without cracking of the concrete but usually it accompanies cracking or cracking of the concrete will happen shortly thereafter. For spalling the following information should be noted:

- Extent and number of affected areas

- Depth of failure

- Degree of detachment

- State of reinforcement corrosion

- Surface discolouration effects

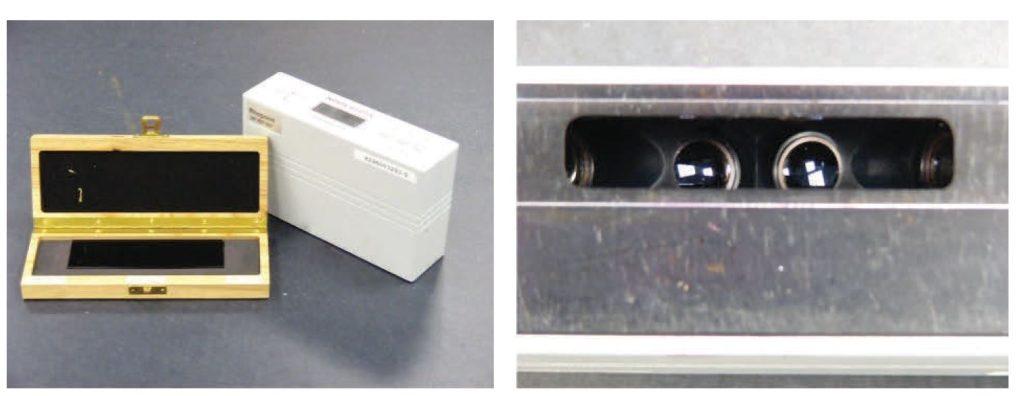

Glossmeter

A glossmeter measures specular reflection, or the capacity of a surface to reflect light. It is a scientific test internationally recognised to allow comparison of measurement values. As it is measuring the “gloss”

of the surface of a material, the more direct light that is reflected, the more obvious will be the impression of gloss. Hence, smooth and polished surfaces reflect more light than rough surfaces as the light is diffusely scattered in all directions.