Case 2

- Introduction

- Causes of Defects

- Good Practices

- Standards

- Maintenance and Diagnostics

- Remedial

- Similar Cases

- References

Maintenance and Diagnostics

- Discharge pipe system should be kept clean regularly in order to maintain maximum efficiency.

- Care should be taken when using chemical descaling agents which are often of a corrosive nature. Therefore, it is important to clearly identify the materials used in the system before using the chemicals.

Carry out regular cleaning by chemical and mechanical applications (e.g., alkaline or solvent cleaning

agents, hydrofluoric acid, air or water abrasive cleaning) and clear dirt regularly in accordance with SS 509-1, BS 8221-1 or equivalent. Remove moulds, lichens and other growths with a stiff brush and treat the residue with biocide chemicals. Use paint, which does not support mould growth. If affected, remove infected paint and sterilise the surface by applying a fungicide solution/algaecide solution to prevent recurrence in accordance with BS 6150, BS EN ISO 1513, SS 542 or equivalent.

The following solutions are recommended for different types of deposits:

| Type of scale | Cleaning method | Possible Locations |

| Deposits due to misuse of the discharge system | Blockage due to large objects or compacted masses such as toilet paper and sanitary towels can be loosened by rodding. | Discharge pipe |

| Lime scale | Periodic de-scaling using a suitable inhibited acid based cleaners (see Table NG.2 in BS EN:12056-2:2200). | Discharge stack and pipes from urinals |

| Accumulation of greases and soap residuals | This can partially be removed by the use of a plunger, but the most effective way is by flushing the system with a strong solution of soda crystals dissolved in hot water (see Table NG.2 in BS EN:12056-2:2200). | Discharge pipes from sinks or wash basins |

- Periodic inspection and tests are recommended to ascertain any other defects such as water leakages, wear and tear or negligence. Equipment can be used to detect defects accurately and quickly. It is recommended that the maintenance staff should respond as soon as possible once defect is detected.

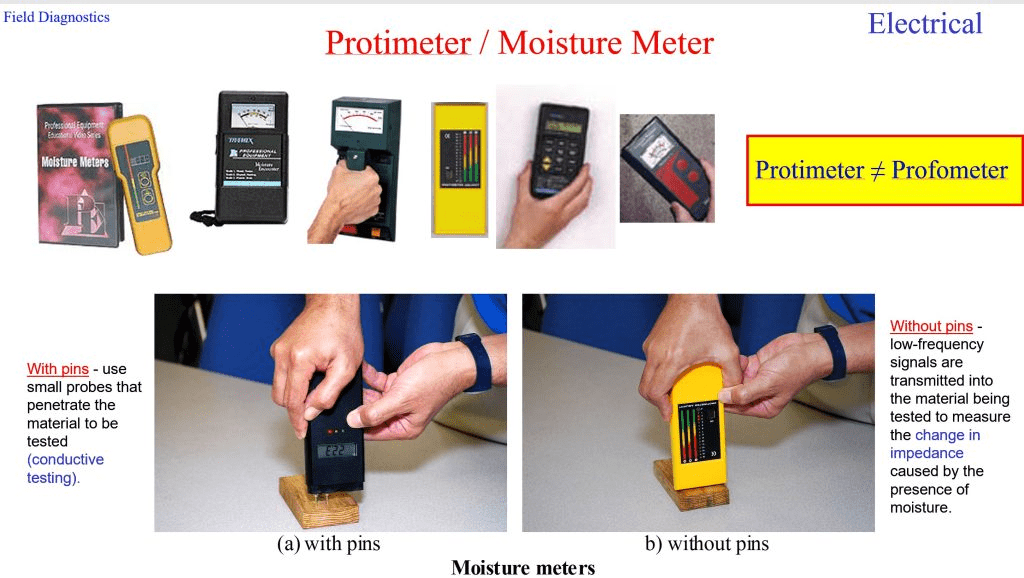

- The following instruments and techniques can be used to detect water leakages in sanitary pipes and biological growth.

Diagnostics of Defect (see also NDT)

Hygrometer

This test can be used to measure the relative humidity level in the room.

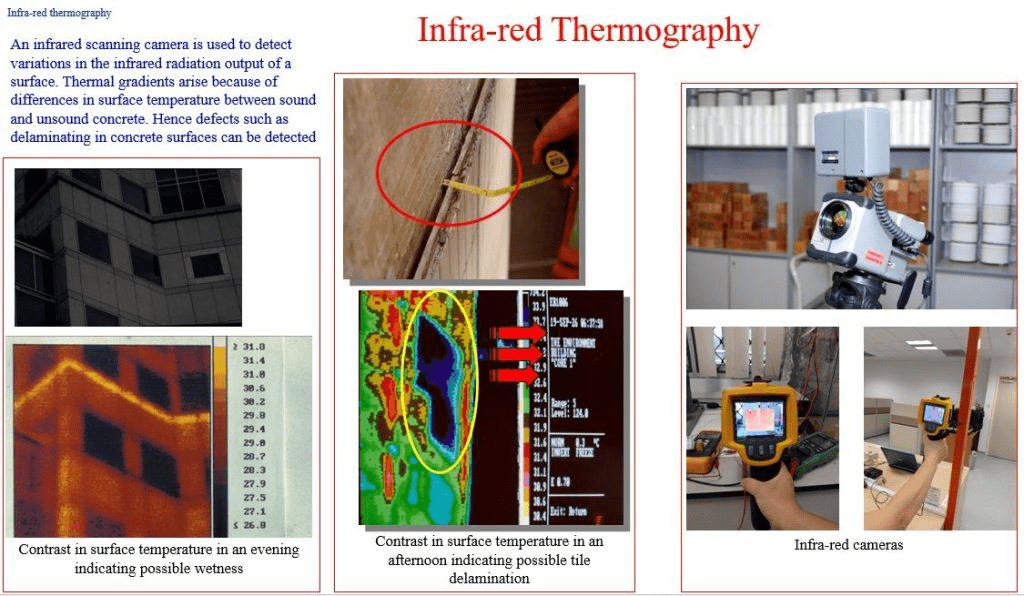

Thermography can be used to identify the position of cracks. A range of crack widths, representing mechanical damage, has been induced under controlled laboratory conditions. The method is based on the characteristics of heat flow phenomenon, in a conductive medium of specific geometry, which is intended to model predetermined boundary conditions.

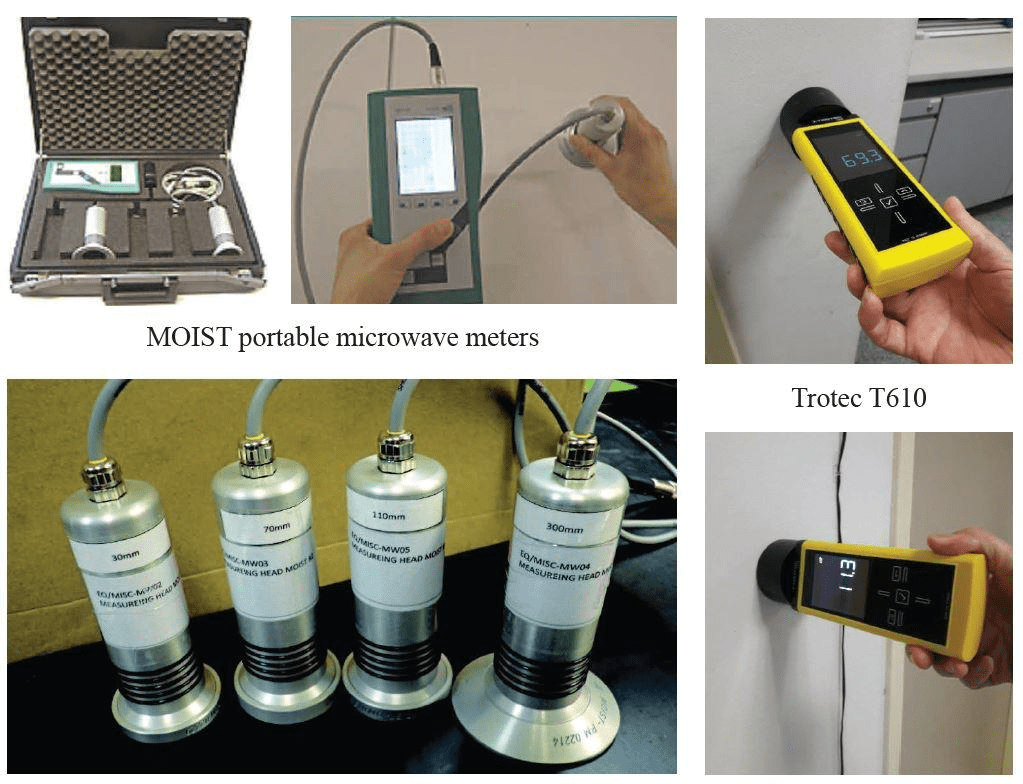

Microwave tomography is a technique to measure the moisture of various materials based on the relatively high dielectric constant of “water” in comparison to the dielectric properties of the material. An electrical field (microwave) is applied to the material, and the microwave induces oscillations of bipolar molecules (i.e., water). Water molecules will reflect and absorb an electrical field during oscillations. A higher electrical field reflected indicates higher water content.

The technique is non-destructive and applicable to wood, brickwork and concrete. The uniqueness of this technique is its ability to measure moisture content at various depths up to 110 mm, allowing the plotting of a 3-D contour of moisture content and facilitating the tracing of the water source.