Case 3

Navigation

- Introduction

- Causes of Defects

- Good Practices

- Standards

- Maintenance and Diagnostics

- Remedial

- Similar Cases

- References

Maintenance and Diagnostics

- It is known that good quality concrete does not require extensive maintenance. However, due to external factors it might deteriorate even before reaching its design life, resulting in cracking and spalling.

- An efficient inspection system should be adopted to ensure the conduct of regular checks such as visual regular inspections should be carried out periodically to detect defects.

- The instruments can be used extensively to diagnose defects and to take remedial action to keep the structure in good condition.

- The following instruments and techniques can be used to detect excessive carbonation and cracks in concrete structures.

Diagnostics of Defects (see also NDT)

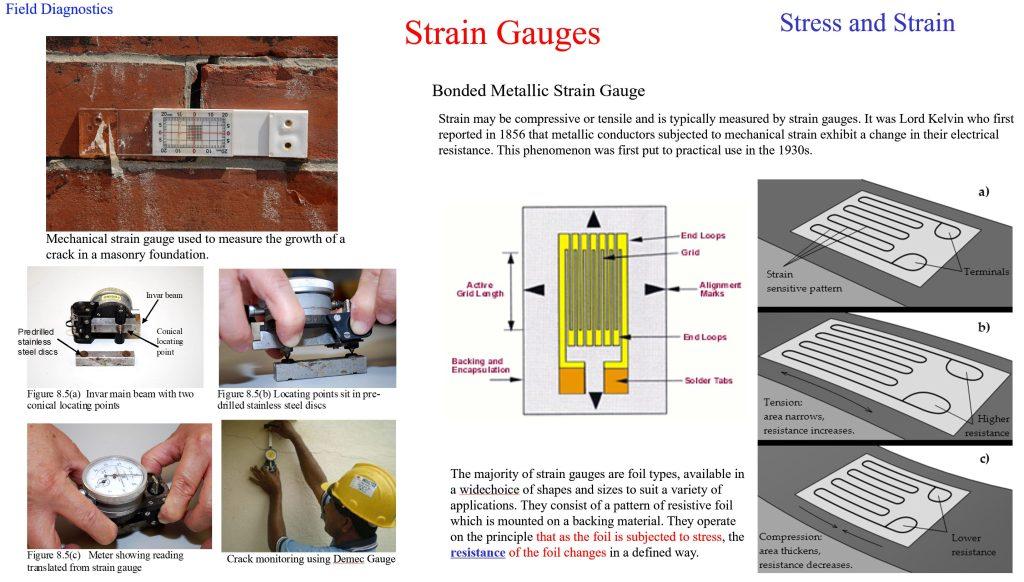

The crack type of crack should first be determined via testing (utilizing a mechanical strain gauge)

Hammer Tapping Test

Tapping test may be used to detect hollowness, delamination, spalled or debonded plaster.by listening to the ‘void’ sound.