Aluminium

Property

Constituents

Commercial aluminium is generally 99.0% – 99.6% pure. Aluminium is not found in its pure state by reasons of its chemical reactivity, thus it is in combination with other elements.

It is the most common metallic element in the earth’s crust which contains approximately 15% of Al2O3 (8% aluminium). [2]

Typical composition of commercially pure aluminium:

| Al | Si | Fe | Cu | Mn | Mg | Zn | Ti |

| 99.5% | 0.2% | 0.2 % max | 0.04% max | 0.03 % max | 0.03 % max | 0.03 % max | 0.03 % max |

Source: Hornbostel, Caleb; Construction Material – Types, Uses and Application; John Wiley & Sons; New York; 1991 [3]

Colour and Profile

Alloy Types

Aluminium is seldom used in its pure form but is normally alloyed with small proportion of other elements [2,3]. Typical of those are:

- Copper

- Manganese

- Silicon

- Magnesium

- Zinc

In the alloying furnace, the aluminum ingot is melted, and mixed with alloying metals like Magnesium, silica, copper, etc to form an aluminium alloy which offers a wide range of specific material properties. The physical properties of the alloy are very much determined by the alloy content. For example:

- Manganese offers good corrosion resistance

- Magnesium is good for welding applications

- Copper yields excellent machinability

- Zinc tends to offer very high strength

Classification

According to BS 1490, casting alloys are designated by numbers in sequence of development which would be preceded by the letters LM (light metal), i.e. LM6.[2]

In US, 4 digit system is used [2,3]:

| First digit | Major alloying element |

| 1xx.x | Pure aluminium (> 99%) |

| 2xx.x | Copper |

| 3xx.x | Silicon + copper and/ or magnesium |

| 4xx.x | Silicon |

| 5xx.x | Magnesium |

| 6xx.x | Magnesium + Silicon |

| 7xx.x | Zinc |

| 8xx.x | Tin |

| 9xx.x | Other elements |

Source: Doran, DK; Newnes Construction Material – Pocket Book; Butterworth- Heinemann Ltd; Oxford; 1994 [2],

Hornbostel, Caleb; Construction Material – Types, Uses and Application; John Wiley & Sons; New York; 1991 [3]

Examples of 4 digits numerical alloy nomenclature system [2]:

| . | Alphanumerical system | Major alloying elements |

| 3103 | Al Mn1 | Manganese |

| 5083 | Al Mg 4.5Mn | Magnesium |

| 6082 | Al Si1 Mg Mn | Magnesium and silicon |

Source: Doran, DK; Newnes Construction Material – Pocket Book; Butterworth- Heinemann Ltd; Oxford; 1994 [2]

In Asia, the most popular 6xxx series alloys are 6xxx series aluminium extrusion alloys.

Workability

It can be riveted, bolted, welded, brazed and soldered. [3]

Solubility of Other Metals [3]

| Silicon, copper, iron, zinc, tin, manganese | Soluble |

| Sodium and potassium | Insoluble |

| Titanium, vanadium, boron, nickel, and chromium | Low solubility |

| Hydrogen | Soluble in aluminium |

Source: Hornbostel, Caleb; Construction Material – Types, Uses and Application; John Wiley & Sons; New York; 1991 [3]

Finishes

Anodized

The durability of anodising is a direct result of it fusing into the surface of the aluminium forming a hard oxide coating. It comes in a wide range of colours and recently it comes with much tighter control for colour matching.

It is difficult to obtain regularity in colour. However, anodising is being increasingly specified by architect for its durability and because it allows the metallic quality of the aluminium to remain visible.

Anodizing is an electrolytic coating process, and the metal deposit and colour is dependent upon time and current passed. [21]

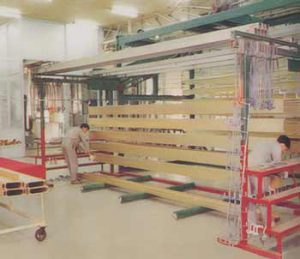

Liquid organic coating (i.e. Fluorocarbon or PVDF or PVF2)

Polyester powder coating

When using polyester powder coating careful specification and monitoring is required to ensure that a thoroughly tested polymer is used and good adhesion achieved. [21]

The powder coating process consists of three main stages: [19]

- Pre-treatment (involves the application of zinc phosphate conversion coatings)

- Spraying the powder

- Fusing the powder by heat treatment

It is possible to specify polyester powder coating, which includes anti-bacterial agents in the coating. This will kill common bacteria, such as Escherica coli, Salmonella and MSRA, which comes into contact with the coated component

Mill finished (= unfinished)

This is not a sufficient protection for a corrosive or marine environment and has a relatively consistent grey appearance, which can be describe as sugary. Marine cast aluminium component is often specified as polished, which can be expensive finish and needs regular maintenance. [21]

Density

The density of aluminium is approximately one-third that of steel and copper. The density of pure aluminium is 2.6898 g/cm-3. With alloying elements in form of cast and wrought alloys, aluminium density range from 2.66 to 2.80g/cm-3. [2]

Modulus Elasticity

Pure aluminium has Young modulus of 68.3GPa, whilst for high strength with copper alloy may be as high as 74GPa [2].

Thermal Expansion

Pure aluminium has a coefficient of thermal expansion approximately twice that of steel at 23.5 x 10-6 /ºC in the range 10-100 ºC.

Alloying elements have a small effect on this value. Figures in the range 20-25 x 10-6 /ºC (for casting alloys) to 20-24 x 10-6 /ºC for wrought alloys. [2]

Thermal Conductivity

Aluminium is a good conductor of heat with conductivity for pure aluminium of 244 W/m ºC (about 4.5 times that of steel).

The thermal conductivity reduces with the increased alloying to 109 W/m ºC for wrought alloys and to below 100 W/m ºC for some casting alloy. [2]

Service Temperature Limit

Melting point: 658.7ºC (but the melting point of some alloys can as low as 530ºC)

Boiling point: 2467ºC

At temperature below zero, aluminium and aluminium alloys exhibit higher tensile strength and elongation than at room temperatures. No alloys suffer low temperature brittleness and there is no point below which brittle fracture occurs.

Aluminium and its alloys show considerable reduction of strength at temperature above 100ºC. At 200ºC the strength is approximately half of that at room temperature. By 350ºC, most alloys will have lost most of their strength. Strength is not restored as temperature falls as the effect of work hardening will have been removed [2].

Strength

The strength of aluminium depends on the composition and on the thermal and mechanical treatment to which it has been subjected.

Its strength can be increased by alloying and proper working to as high as 689.5 MN/m².

Specific Gravity

2.6989 at 20ºC

Tensile Strength

48.265 MN/m2 for 99.996% pure aluminium

Corrosion Resistance

Aluminium is readily attacked by alkalis and hydrochloric acid and slowly attacked by dilute acids. It is inert to sulphur. In direct contact with metals other than zinc, cadmium, magnesium, and on magnetic stainless steel, aluminium is subject to certain types of galvanic action and should therefore be electrically insulated from other metals [3].

This normally occur in aggressive environments, particularly in industrial areas. Aluminium’s natural corrosion resistance stems from rapid dormation on untreated metal of a permanent film of the natural aluminium oxide, rendering the material inert resistance of the finished product.

Electrical Resistance and Conductivity

Pure aluminium has a high electrical conductivity at 63% of IACS and an electrical resistivity of 2.69 µ cm at 20ºC. These values increase with alloying to a resistance of over 6 µ cm at 20ºC for some alloys and conductivity down to below 28% IACS. [2]

Fire Resistance

Where fire resistance is required, sufficient insulation must be provided to prevent the temperature of metal from rising above 200ºC. [2]

Acid Resistance

Aluminium is found to be resistant to the attack of nitric acid, dissolves slowly in concentrated sulphuric acid and is soluble in hydrochloric acid. At normal temperature, it is not affected by sulphur, carbonic acid, carbonic oxide, vinegar, sea water, etc. But it is rapidly corroded by caustic alkalis. [19]

Fatigue

Typical value of fatigue strength at 50 x 106 cycles range from 20MPa for annealed commercially pure aluminium to 124 MPa for 6082-TG material. Alloys with high manganese contents will exhibit higher values. Fatigue strength may be drastically reduced by unsatisfactory weld details. [2]

Creep

Only commercially pure aluminium shows significant creep at room temperature. However, if the working temperature is held at around 200-250ºC, then the creep of some alloys will be significant. [2]

Reflectivity

For pure aluminium with a clean bright surface 80%-85% of visible incident radiation and about 90% of heat will be reflected. Emissivity is typically 0.30 for a wavelength of 0.65 µmm. [2]