Case 1

- Introduction

- Causes of Defects

- Good Practices

- Standards

- Maintenance and Diagnostics

- Remedial

- Similar Cases

- References

Maintenance and Diagnostics

Maintenance

Regular inspections and checking should be hence carried out periodically at regular intervals to detect these defects and to take remedial action to remove these defects. An efficient inspection system should be adopted to ensure the conduct of regular checks such as visual inspections periodically.

Suitable instruments and techniques should be used to diagnose defects properly. Diagnosis involves a process in which experts investigate the buildings’ conditions, carry out tests, evaluate, make recommendations for remedial actions where necessary and predict the future performance of a building.

Periodic maintenance to ensure its continued successful performance is necessary.

Although the brick units are quite durable over time, other materials in the wall system will require periodic repair and/or replacement.

Typical maintenance items which should be addressed are repairing of cracks in masonry, cleaning clogged weep holes, removing stains and efflorescence, repainting steel, replacing caps or copings, repointing mortar joints (tuckpointing), replacing deteriorated sealants and caulking, and cleaning the masonry. For decisions on surface repairs, consider the ease of access for future work, relative cost of hiring and erecting scaffolding, and the probable frequency of maintenance in accordance with BS 8221-2, SS 509-2 or equivalent. Record and retain documentation of all executed works on façades, including photographs and non-destructive survey techniques, to provide background information prior to further assessment or work. Carry out semi-annual inspections of stone-wall elements and inspect all elevations. Keep accurate and cumulative records of inspection findings in accordance with ASTM C1496, BS 8298-1 or equivalent.

Regular cleaning is critical for the long-term durability and appearance of natural stone façades. Perform periodic joint repairs (i.e., sealant replacement, tuck pointing, and cleaning) in accordance with ASTM C1496, BS 8298-1 or equivalent. Perform repairs and restoration works in accordance with ASTM C1722-18, BS 8221-2 or equivalent. For cases of cracked or broken stones, carry out the following:

a) Seek assistance for stone replacement;

b) Tuck point or caulk crack with sealant if fragments are stable and secure;

c) Monitor closely for additional cracking or movement.

Diagnostics of Defect (see also NDT)

Visual Inspection

The examination record should note their position and orientation (e.g. vertical, horizontal or diagonal), their length and their displacement (i.e. the amount by which their sides have moved apart).

Displacement should be measured on three axes, to record movement vertically, sideways and forwards.

If a crack has opened more at one end than at the other, this is a useful pointer as to its cause and therefore should be noted.

To assist in the observation of any future growth in the length of a crack, its current extent can be indicated by a small mark in waxed chalk or paint at each end.

A more common practice used to monitor the growth of cracks is by applying pads of cement mortar to the surface of the brickwall across the crack at suitable locations, with the date written on each pad. Further development of the crack fractured the pad and the resulting gap could be measured; reasonable accuracy was achieved by using a simple crack width gauge. Other ways of measuring crack width is shown in the figure.

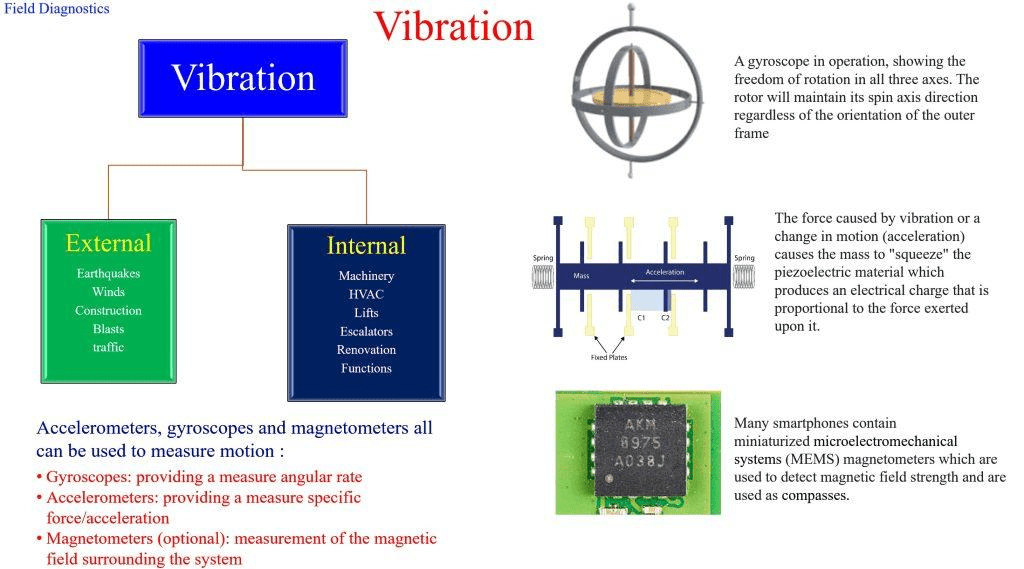

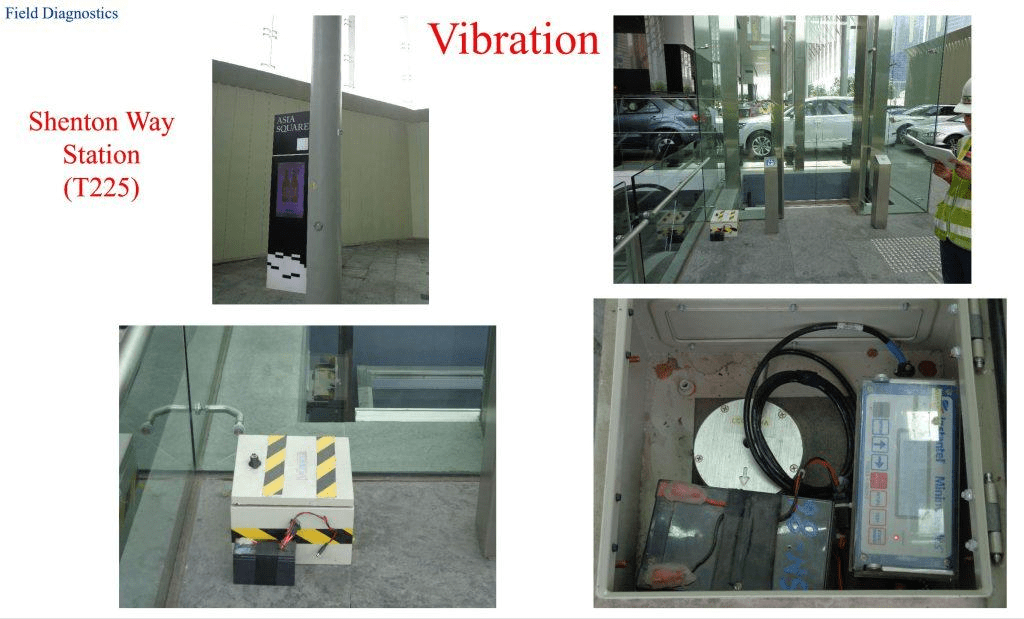

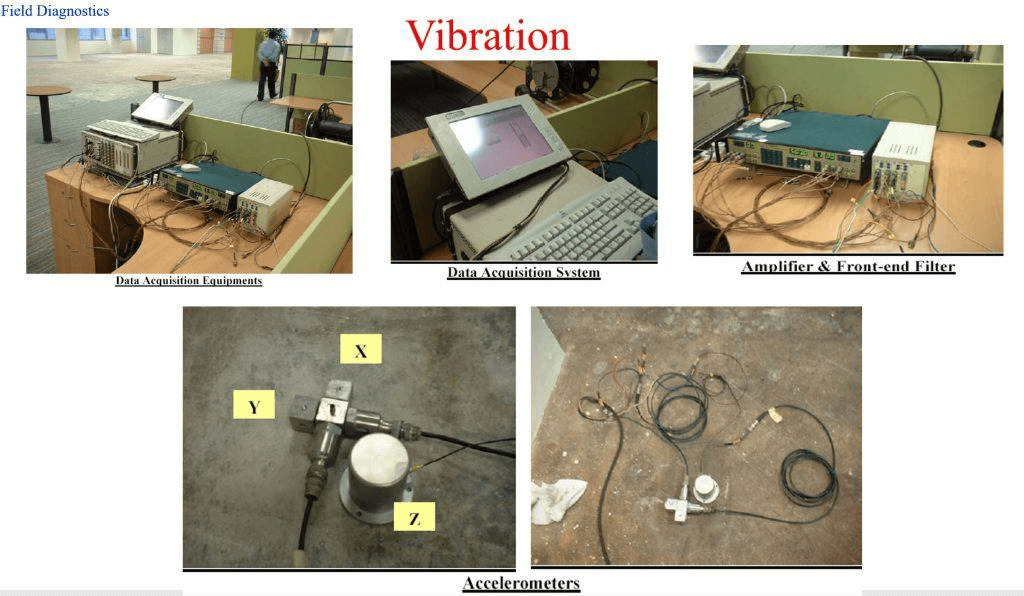

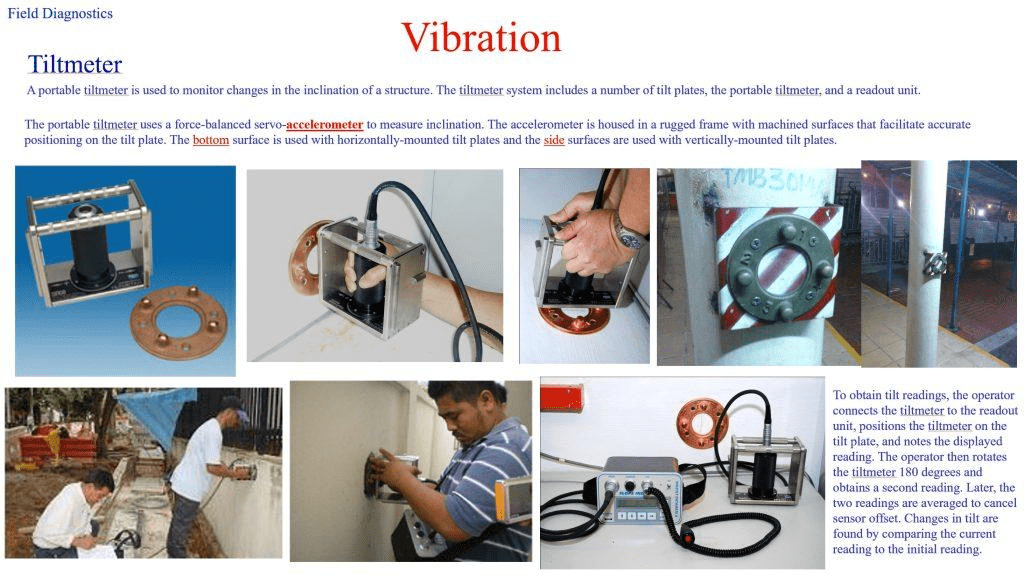

Vibration

Vibration may be (i) continuous (with magnitudes varying or remaining constant with time, e.g., machinery), (ii) impulsive (infrequent and occasional, e.g., heavy crane loading and unloading), or (iii) intermittent (with the magnitude of each event being either constant or varying with time, e.g., trains, impact pile driving, jackhammers). Common instrumentation used to measure such motions includes

gyroscopes, accelerometers and magnetometers.

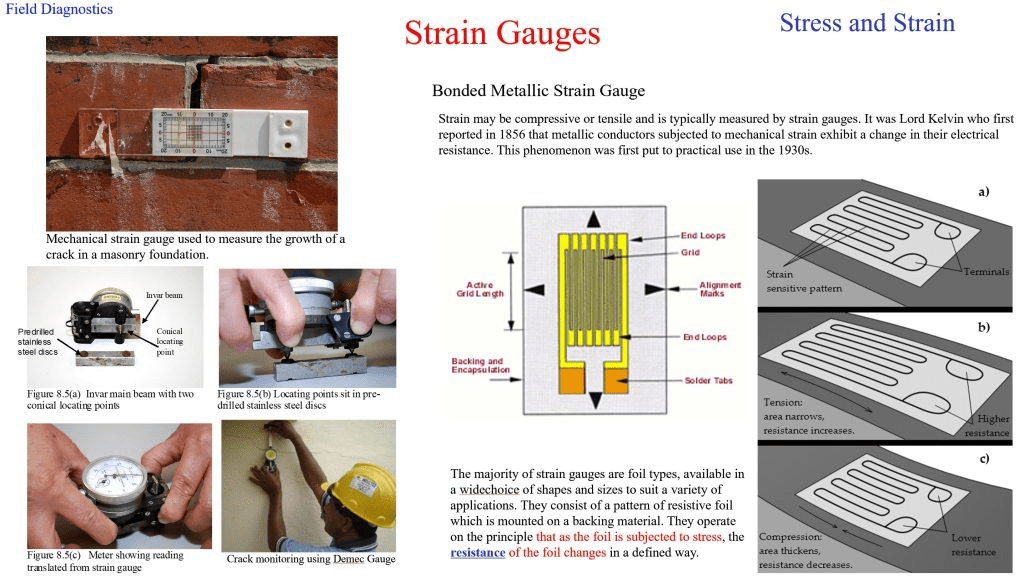

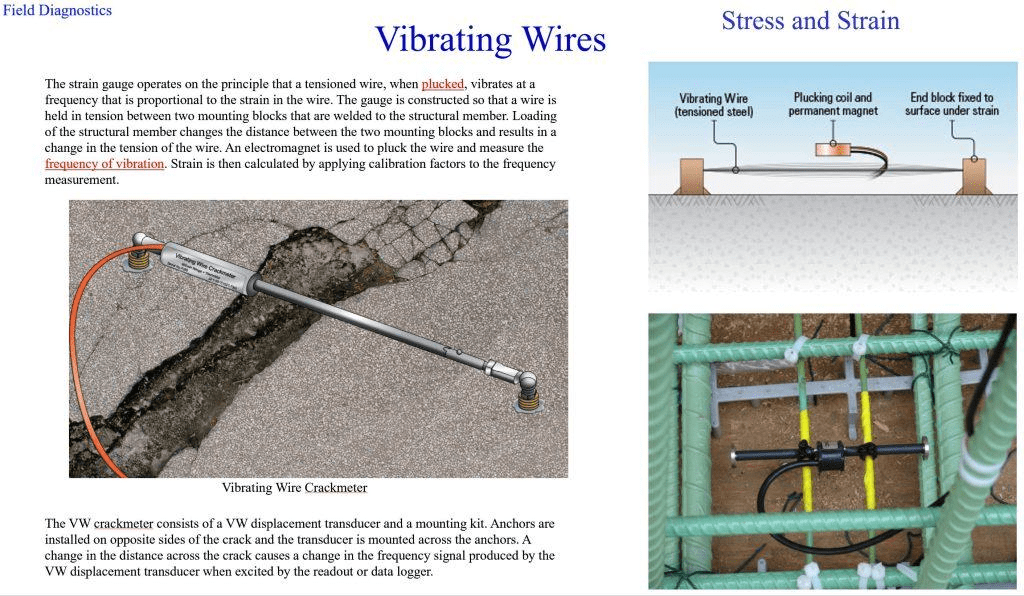

Strain Gauges

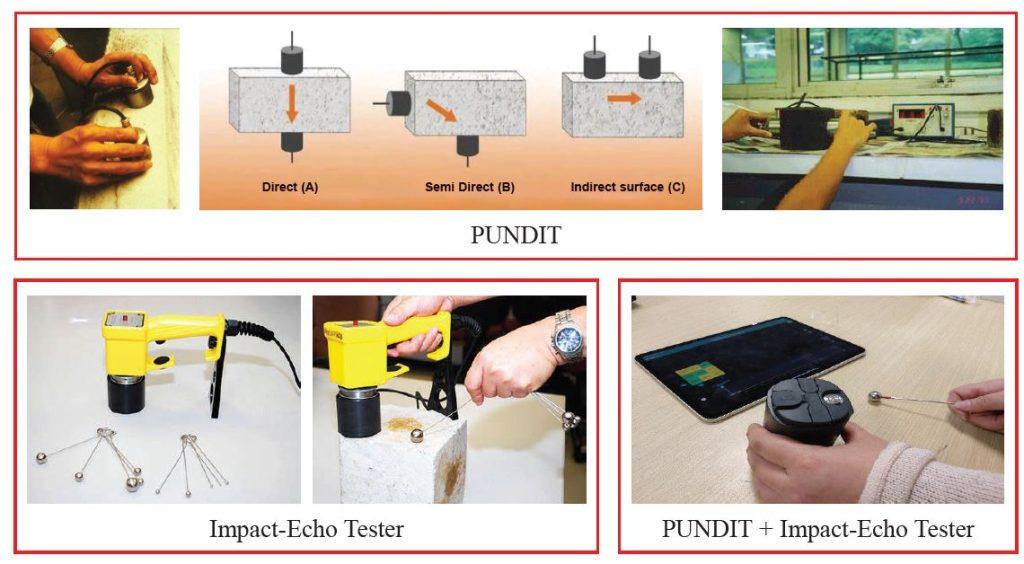

Ultrasonic Pulse Velocity (UPV)

UPV can identify non-homogeneous conditions such as voids, cracks and honeycombs using the optional hand-held terminal. This method can also be used to estimate the depth of cracks.